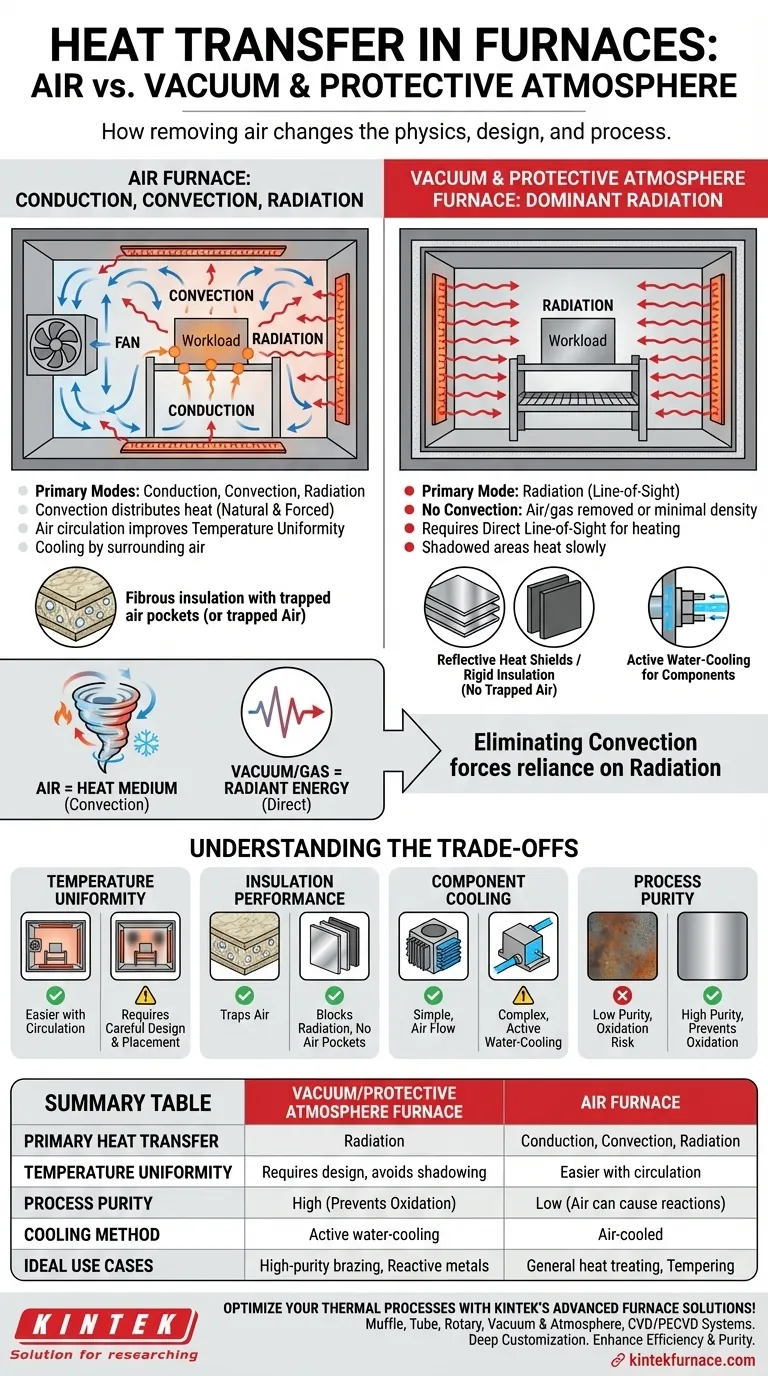

In a vacuum or protective atmosphere furnace, the primary method of heat transfer is radiation, whereas a standard air furnace relies on a combination of conduction, convection, and radiation. The absence of air fundamentally changes the physics of how heat moves from the heating elements to the workload, impacting furnace design, material selection, and temperature uniformity.

The core difference is the elimination of convection. Removing air (the medium for heat convection) forces the system to rely almost entirely on line-of-sight thermal radiation, which has significant consequences for both heating efficiency and component design.

The Three Modes of Heat Transfer: A Primer

To understand the difference, it's essential to recognize the three ways heat can move. Every furnace uses these, but their balance shifts dramatically based on the furnace's internal environment.

Conduction

Conduction is heat transfer through direct physical contact. Heat moves from a hotter part of an object to a colder part, or from one object to another touching it. This occurs in all furnace types, for example, through the racks holding a part or within the part itself.

Convection

Convection is heat transfer through the movement of a fluid, such as a gas or liquid. In an air furnace, air near the heating elements gets hot, becomes less dense, and rises. Cooler, denser air sinks to take its place, creating a current that circulates heat throughout the chamber.

Radiation

Radiation is heat transfer via electromagnetic waves, primarily in the infrared spectrum. A hot object, like a heating element, emits this energy, which travels through space (or a vacuum) until it is absorbed by another object, such as the workpiece.

How Air Furnaces Transfer Heat

Air furnaces are the workhorses of many thermal processes because they leverage all three modes of heat transfer, with convection playing a starring role.

The Power of Convection

The air inside the furnace acts as a medium, creating natural convection currents that distribute heat. This process helps to average out the temperature within the chamber, reducing hot and cold spots.

Forcing Uniformity

Many air furnaces also include fans to create forced convection. This powerful circulation of hot air dramatically increases the rate of heat transfer and promotes excellent temperature uniformity, even for parts with complex geometries.

The Physics of Vacuum & Protective Atmosphere Furnaces

When you remove the air from a furnace, you fundamentally alter the heat transfer equation.

Eliminating Convection

Pulling a vacuum removes the air molecules necessary for convection. Similarly, while a protective atmosphere (like argon or nitrogen) is present, its density and heat-carrying capacity are far lower than air, drastically reducing the effect of convection.

Radiation Becomes Dominant

With convection gone, thermal radiation is the only significant way to move heat from the elements to the workload. This means heat travels in a straight line from the hot surface to any cooler surface that can "see" it.

The Impact on Furnace Design

This reliance on radiation has critical design implications. Heating elements must be placed to ensure they have a direct line of sight to all surfaces of the workpiece. Any part of the workload "shadowed" by another part or a fixture will heat up much more slowly.

Understanding the Trade-offs

The choice between furnace types is a decision based on balancing process requirements with physical limitations. The difference in heat transfer creates distinct advantages and disadvantages.

Temperature Uniformity

Air furnaces can often achieve superior temperature uniformity more easily due to air circulation. Achieving uniformity in a vacuum furnace requires careful part placement and sophisticated heating element design to avoid radiant "shadowing."

Insulation Performance

Conventional fibrous insulation works by trapping air in small pockets, which stops convection. In a vacuum, this insulation is useless because the trapped air is removed. Vacuum furnaces must instead use multi-layer heat shields made of reflective metals (like molybdenum) or specialized rigid graphite insulation boards designed to block radiant heat.

Component Cooling

In an air furnace, components like electrical connections and induction coils are cooled by the surrounding air. In a vacuum, there is no air for cooling. Therefore, critical components in a vacuum furnace must be actively water-cooled, adding complexity and cost to the system.

Process Purity

The key advantage of a vacuum or protective atmosphere is the prevention of oxidation and other surface reactions. For reactive metals like titanium or for high-purity brazing and medical implant applications, this non-reactive environment is non-negotiable.

Making the Right Choice for Your Process

Your specific goal determines which thermal environment is appropriate.

- If your primary focus is process purity and preventing oxidation: A vacuum furnace is essential. It provides the cleanest possible environment for sensitive materials and applications like brazing or medical device manufacturing.

- If your primary focus is cost-effective, uniform heating of non-reactive materials: An air furnace, especially one with forced convection, is often the most efficient and economical choice for general heat treating, tempering, and curing.

- If your primary focus is precise control over complex thermal cycles: A vacuum furnace with rapid gas-quenching capabilities offers unparalleled control. It allows for pure radiant heating followed by rapid, convection-assisted cooling in a single, controlled cycle.

Ultimately, choosing the correct furnace is about matching the physics of heat transfer to the specific metallurgical or chemical outcome you need to achieve.

Summary Table:

| Aspect | Vacuum/Protective Atmosphere Furnace | Air Furnace |

|---|---|---|

| Primary Heat Transfer | Radiation | Conduction, Convection, Radiation |

| Temperature Uniformity | Requires careful design to avoid shadowing | Easier to achieve with air circulation |

| Process Purity | High (prevents oxidation) | Low (air can cause reactions) |

| Cooling Method | Active water-cooling | Air-cooled |

| Ideal Use Cases | High-purity brazing, reactive metals | General heat treating, tempering |

Optimize your thermal processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs, enhancing efficiency and purity. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation