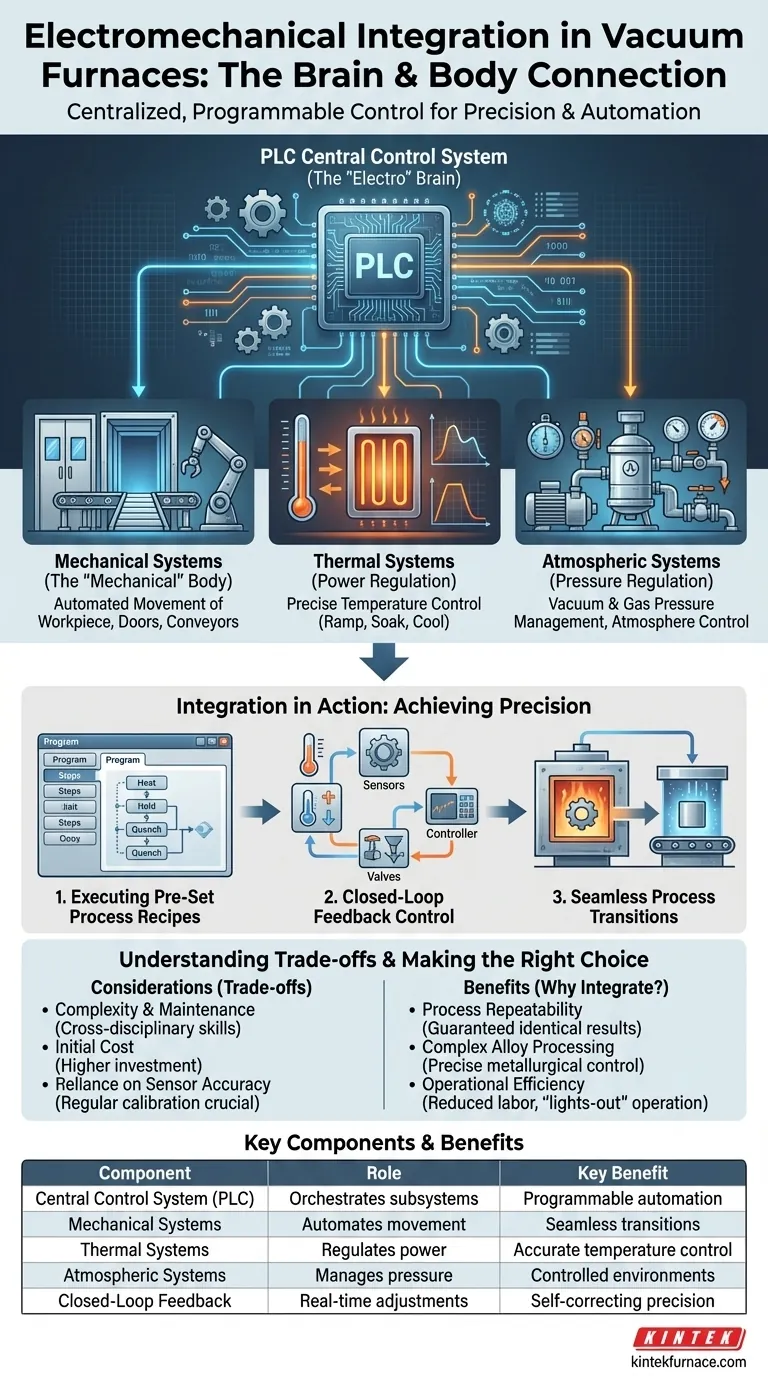

At its core, the high degree of electromechanical integration in a vacuum furnace stems from its use of a centralized computer to precisely control all mechanical actions, thermal cycles, and atmospheric conditions. This system allows for programmable automation of complex processes like workpiece movement, power regulation to heating elements, and vacuum or gas pressure adjustments, all without manual intervention.

The key insight is not the presence of individual automated parts, but how a single, programmable control system seamlessly orchestrates every mechanical and electrical component to execute a complex heat treatment recipe with extreme precision and repeatability.

The Core Components of Integration

True integration is achieved when the furnace's "brain" (the electrical control system) has complete and precise command over its "body" (the mechanical, thermal, and atmospheric systems).

The Central Control System (The "Electro")

The heart of the integrated furnace is a Programmable Logic Controller (PLC) or an industrial computer. This central controller acts as the brain of the entire operation.

It is responsible for reading the pre-set process steps (the "recipe") and sending real-time commands to all other subsystems.

Mechanical Systems (The "Mechanical")

This refers to all the moving parts of the furnace, which are controlled electronically rather than manually.

Key examples include automated loading and unloading doors, internal conveyor or hearth systems that move the workpiece between heating and cooling zones, and high-speed doors that separate different chambers.

Thermal Systems (Power Regulation)

Integration allows for incredibly precise temperature control. The central controller manages the power regulation to the heating elements (whether resistance or induction).

The system follows a programmed temperature profile, managing ramp-up speeds, holding times (soaks), and cooling rates with high accuracy.

Atmospheric Systems (Pressure Regulation)

A vacuum furnace's primary function is to control the processing atmosphere. Integrated systems automate this entire process.

This includes controlling vacuum pumps to achieve the required vacuum level, managing gas inlet valves for controlled air pressure regulation, and introducing specific backfill gases like nitrogen or argon for cooling or inert processing.

How Integration Delivers Precision and Automation

The seamless connection between these systems is what transforms the furnace from a simple oven into a sophisticated, automated tool for modern manufacturing.

Executing Pre-Set Process Recipes

The user inputs a complete process "recipe" into the control system. This recipe dictates every variable: temperature, time, pressure levels, and when to move the workpiece.

The furnace then executes these pre-set steps for processes like quenching and tempering automatically, ensuring that every cycle is identical to the last. This is the foundation of automation.

Closed-Loop Feedback Control

This is the key to precision. Sensors—such as thermocouples for temperature and vacuum gauges for pressure—constantly feed live data back to the central controller.

The controller compares this real-time data to the desired setpoints in the recipe. If there's any deviation, it instantly adjusts power to the heaters or modulates the gas valves, creating a closed-loop system that self-corrects.

Seamless Process Transitions

Complex treatments often require rapid changes in conditions. For instance, after a high-temperature soak, a part may need to be moved instantly to a separate chamber for rapid gas-fan quenching.

Electromechanical integration makes this transition seamless and automatic, controlling the doors, workpiece movement, and gas flow in a perfectly timed sequence that would be impossible to achieve manually with the same speed or consistency.

Understanding the Trade-offs

While powerful, this high level of integration comes with inherent considerations.

Complexity and Maintenance

An integrated system has interconnected electrical, mechanical, and software components. Troubleshooting a problem can be more complex than on a simple manual furnace and may require a technician with cross-disciplinary skills.

Initial Cost

The sophisticated control systems, sensors, and automated mechanical components result in a significantly higher initial capital investment compared to less-automated or manual furnace systems.

Reliance on Sensor Accuracy

The entire system's precision is fundamentally dependent on the accuracy of its sensors. A faulty thermocouple or a miscalibrated pressure gauge can cause the controller to make incorrect adjustments, potentially compromising the entire batch. Regular calibration is critical.

Making the Right Choice for Your Goal

Understanding electromechanical integration helps you align the furnace's capabilities with your specific manufacturing needs.

- If your primary focus is process repeatability and certification: The automation and precision from an integrated system are non-negotiable for guaranteeing identical results for every batch, which is crucial for aerospace or medical applications.

- If your primary focus is processing complex alloys or sensitive parts: The precise, closed-loop control over heating, cooling, and atmosphere is essential to meet the stringent metallurgical requirements of advanced materials.

- If your primary focus is operational efficiency and reducing labor: A highly integrated furnace minimizes the need for operator intervention, allowing for "lights-out" operation and reducing the potential for human error.

Ultimately, this deep integration elevates heat treatment from a manual craft to a precise and repeatable industrial science.

Summary Table:

| Feature | Role in Integration | Key Benefit |

|---|---|---|

| Central Control System (PLC) | Orchestrates all subsystems | Enables programmable automation and precise recipe execution |

| Mechanical Systems | Automates movement of workpieces and doors | Facilitates seamless process transitions and reduces manual labor |

| Thermal Systems | Regulates power to heating elements | Ensures accurate temperature control for consistent results |

| Atmospheric Systems | Manages vacuum and gas pressures | Maintains controlled environments for sensitive processes |

| Closed-Loop Feedback | Uses sensors for real-time adjustments | Provides self-correcting precision and repeatability |

Elevate your laboratory's capabilities with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering superior precision, automation, and efficiency for complex heat treatments. Contact us today to discuss how our integrated systems can transform your processes and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity