In the medical field, vacuum brazing is the definitive process for manufacturing critical components where failure is not an option. It is used to create exceptionally strong, pure, and hermetically sealed joints for devices like surgical instruments, diagnostic equipment, and life-sustaining implants. The process is chosen because its controlled vacuum environment prevents oxidation and eliminates the need for corrosive fluxes, ensuring the highest level of biocompatibility and cleanliness required for patient safety.

The core challenge in medical device manufacturing is achieving absolute reliability and purity in every component. Vacuum brazing directly addresses this by creating flawless, contaminant-free bonds that are stronger and more sterile than those made by nearly any other joining method.

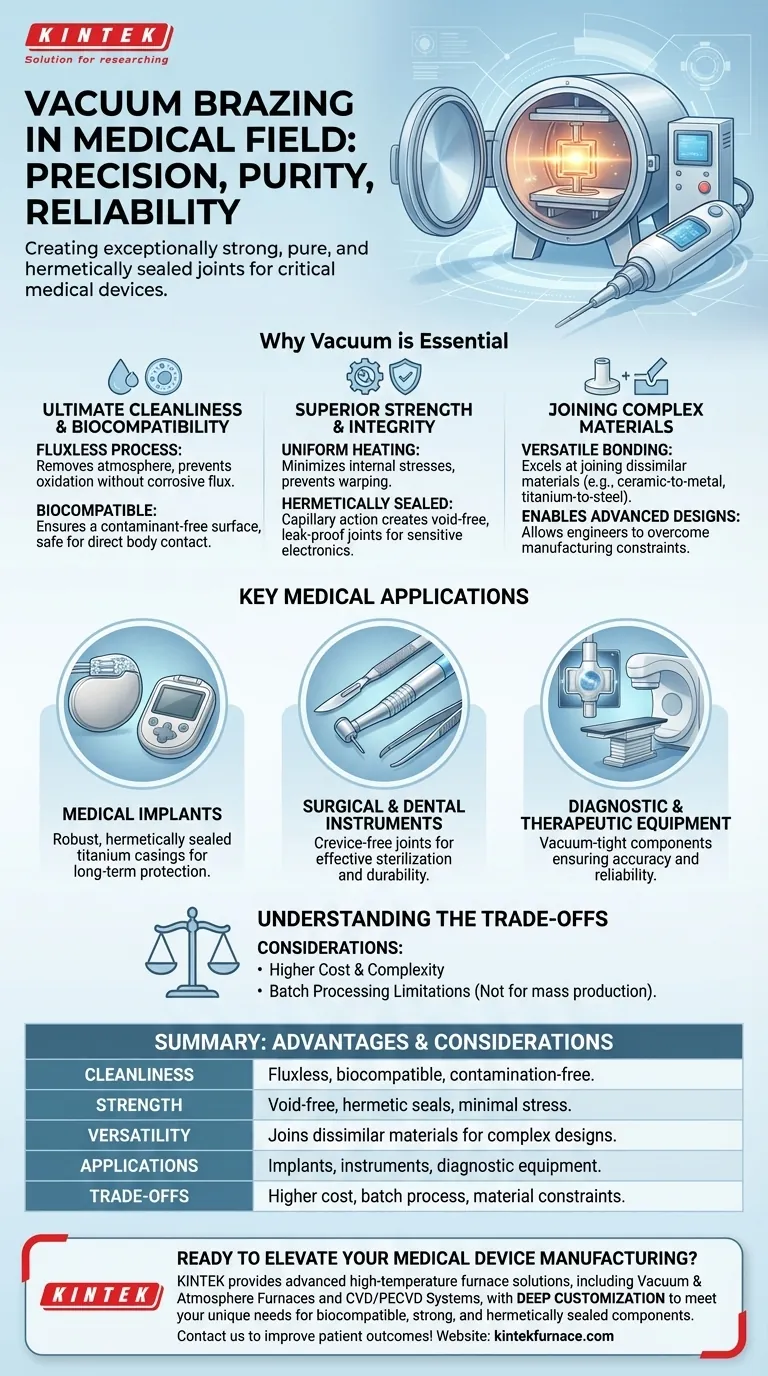

Why Vacuum is Essential for Medical Devices

The decision to use vacuum brazing is driven by the uncompromising demands of the medical industry. The unique environment of a vacuum furnace provides three fundamental advantages: ultimate cleanliness, superior structural integrity, and the ability to join complex materials.

Achieving Ultimate Cleanliness and Biocompatibility

Traditional joining methods often use a chemical flux to clean metal surfaces, which can leave behind corrosive or toxic residue. In a medical context, this is unacceptable.

Vacuum brazing is a fluxless process. By removing the atmosphere, the vacuum itself prevents oxides from forming on the metal parts during high-temperature heating, ensuring a perfectly clean surface for the braze filler to bond with. This results in a joint free of contaminants, making it inherently biocompatible and safe for direct contact with the human body.

Ensuring Uncompromised Joint Strength and Integrity

A vacuum furnace provides slow, uniform heating and cooling for the entire assembly. This minimizes internal stresses that can cause parts to warp or crack, a common issue with localized heating methods like welding.

The filler metal is drawn into the gap between components by capillary action, creating a complete, void-free joint. This results in connections that are hermetically sealed and leak-proof, which is essential for protecting sensitive electronics inside an implant or containing materials within diagnostic equipment.

Joining Complex and Dissimilar Materials

Modern medical devices are often complex assemblies of different materials chosen for their specific properties. Vacuum brazing excels at joining dissimilar materials, such as bonding a ceramic insulator to a titanium casing or a carbide tip to a stainless steel instrument. This versatility allows engineers to design more advanced and effective devices without being limited by manufacturing constraints.

Key Medical Applications of Vacuum Brazing

The principles of cleanliness, strength, and versatility make vacuum brazing the go-to solution for a range of high-stakes medical applications.

Medical Implants

For devices like pacemakers, defibrillators, and drug-delivery pumps, the outer casing must be perfectly sealed to protect the internal electronics from bodily fluids for decades. Vacuum brazing creates the robust, hermetically sealed titanium casings that make these life-saving devices possible.

Surgical and Dental Instruments

Reusable surgical tools must withstand repeated, aggressive sterilization cycles. Vacuum brazing creates smooth, crevice-free joints between different parts of an instrument, such as a hardened steel tip and a stainless steel handle. This eliminates microscopic gaps where bacteria could hide, ensuring effective sterilization.

Diagnostic and Therapeutic Equipment

Complex machinery like X-ray tubes, linear accelerators, and other radiation therapy equipment rely on vacuum-tight components to function. Vacuum brazing is used to assemble these components, ensuring the integrity and reliability needed for accurate diagnostics and safe patient treatment.

Understanding the Trade-offs

While powerful, vacuum brazing is a specialized process with specific considerations. It is not the right choice for every application.

High Cost and Complexity

Vacuum furnaces represent a significant capital investment, and operating them requires highly skilled technicians. The overall process is more expensive and time-consuming than standard welding or soldering.

Batch Processing Limitations

Vacuum brazing is a batch process. Parts must be carefully assembled, loaded into the furnace, run through a long heating and cooling cycle, and then unloaded. This limits throughput compared to continuous joining methods and is best suited for high-value components rather than mass production.

Design and Material Constraints

The process requires that parts be designed to allow for capillary action and that all materials involved are stable under high heat and vacuum. Materials with high vapor pressures, for instance, cannot be used as they would contaminate the vacuum environment.

Applying This to Your Project

When evaluating vacuum brazing, your primary goal will determine if its benefits justify the investment.

- If your primary focus is implantable devices: Vacuum brazing is often non-negotiable for achieving the required hermetic sealing and absolute biocompatibility.

- If your primary focus is reusable surgical tools: Use this process to create durable, crevice-free joints that guarantee sterilizability and a long service life.

- If your primary focus is high-performance equipment: Choose vacuum brazing for joining dissimilar materials in complex assemblies that demand vacuum integrity or superior strength.

Ultimately, vacuum brazing empowers engineers to create safer, more reliable, and more advanced medical devices that directly improve patient outcomes.

Summary Table:

| Aspect | Key Details |

|---|---|

| Cleanliness | Fluxless process prevents oxidation, ensures biocompatibility, and eliminates contaminants for safe medical use. |

| Strength | Capillary action creates void-free, hermetically sealed joints with minimal stress for high reliability. |

| Versatility | Joins dissimilar materials like ceramics and metals, enabling complex device designs. |

| Applications | Used in implants (e.g., pacemakers), surgical instruments, and diagnostic equipment for durability and sterility. |

| Trade-offs | Higher cost, batch processing, and material constraints compared to other methods. |

Ready to elevate your medical device manufacturing with precision and reliability? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for biocompatible, strong, and hermetically sealed components. Contact us today to discuss how our expertise can enhance your projects and improve patient outcomes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing