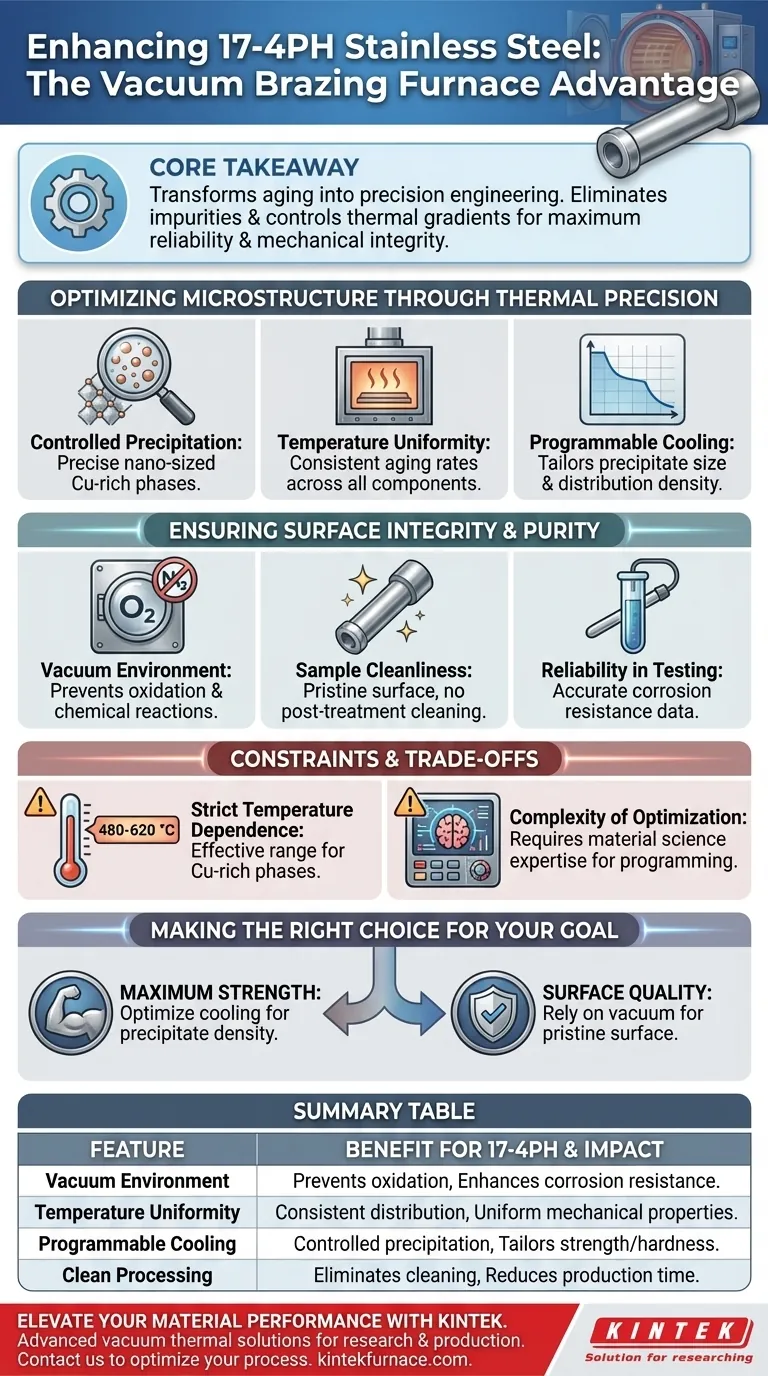

Using a vacuum brazing furnace for the aging treatment of 17-4PH stainless steel significantly enhances material performance by providing superior temperature uniformity and programmable cooling rates. This precise thermal environment allows for the controlled precipitation of nano-sized copper-rich phases within the critical 480-620 °C range, while simultaneously preventing surface oxidation.

Core Takeaway The vacuum brazing furnace transforms the aging process from a simple heat cycle into a precision engineering step. By eliminating environmental impurities and strictly controlling thermal gradients, it tailors the size and distribution of strengthening precipitates to ensure maximum reliability and mechanical integrity.

Optimizing Microstructure Through Thermal Precision

Controlled Precipitation

The primary mechanical advantage of using a vacuum brazing furnace is the ability to dictate the microstructure of the steel. The furnace allows for the precise precipitation of nano-sized copper-rich (Cu-rich) phases.

Temperature Uniformity

Achieving the correct phase distribution requires exact temperatures. The vacuum furnace offers superior temperature uniformity compared to standard atmosphere furnaces, ensuring every part of the component ages at the exact same rate.

Programmable Cooling

The equipment features programmable cooling rates. This capability allows operators to tailor the cooling process to achieve specific size and distribution density requirements for the precipitates.

Ensuring Surface Integrity and Purity

Elimination of Environmental Impurities

The vacuum environment isolates the 17-4PH stainless steel from the outside atmosphere. This effectively prevents chemical reactions between the material and environmental contaminants during the heating cycle.

Sample Cleanliness

Because the process occurs in a vacuum, the treated samples remain exceptionally clean. This eliminates the need for post-treatment cleaning and ensures that the surface is pristine.

Reliability in Testing

The high degree of cleanliness directly impacts quality assurance. By preventing surface contamination, the furnace ensures the reliability of subsequent electrochemical testing results, providing accurate data on the material's corrosion resistance.

Understanding the Constraints and Trade-offs

Strict Temperature Dependence

While the furnace offers high precision, the effectiveness of the aging treatment is strictly bound to the 480-620 °C temperature range. Operating outside this window, even with high-end equipment, will fail to produce the desired Cu-rich phases.

Complexity of Optimization

The benefit of "tailored" distribution density implies that the process is not automatic. Utilizing programmable cooling rates requires a deep understanding of the material science involved to set the correct parameters for the specific mechanical properties desired.

Making the Right Choice for Your Goal

To maximize the benefits of a vacuum brazing furnace for 17-4PH, align your process settings with your specific engineering objectives:

- If your primary focus is Maximum Strength: Prioritize the programming of cooling rates to optimize the density and size of the nano-sized Cu-rich precipitates.

- If your primary focus is Surface Quality: Rely on the vacuum environment to prevent oxidation, ensuring the material is ready for electrochemical testing without aggressive cleaning.

By leveraging the precision of vacuum brazing technology, you convert the aging process from a routine step into a critical opportunity for material enhancement.

Summary Table:

| Feature | Benefit for 17-4PH Stainless Steel | Impact on Material Performance |

|---|---|---|

| Vacuum Environment | Prevents surface oxidation and contamination | Enhances corrosion resistance and testing reliability |

| Temperature Uniformity | Ensures consistent phase distribution | Guarantees uniform mechanical properties across parts |

| Programmable Cooling | Controlled precipitation of Cu-rich phases | Tailors strength, hardness, and ductility parameters |

| Clean Processing | Eliminates post-treatment cleaning steps | Reduces production time and maintains pristine surfaces |

Elevate Your Material Performance with KINTEK

Maximize the mechanical integrity of your 17-4PH stainless steel components with KINTEK’s advanced vacuum thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-precision Vacuum, CVD, and Muffle systems designed to meet the strictest aging and brazing specifications.

Whether you need customizable thermal gradients or specialized cooling rates, our lab high-temp furnaces are engineered for your unique research and production needs. Contact KINTEK today to optimize your aging treatment process.

Visual Guide

References

- Chengshuang Zhou, Lin Zhang. The Effect of Aging Treatment on the Corrosion Behavior of 17-4PH Stainless Steel. DOI: 10.3390/ma18081823

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a high-temperature vacuum furnace contribute to the temperature calibration of Co3O2BO3? Unlock Data Precision

- How does the vacuum furnace body contribute to the melting process? Unlock High-Purity Metal Production

- How is a vacuum annealing furnace utilized in the materials science and metallurgy industry? Enhance Material Purity and Performance

- What are the primary benefits of vacuum tempering? Achieve Superior Surface Quality and Enhanced Material Properties

- What is the purpose of using industrial heating during non-productive vacuum degassing phases? Protect Your Assets

- What are the benefits of the degassing effect during vacuum heating? Unlock Superior Metal Performance and Durability

- How does a vacuum furnace improve smelting quality? Achieve Purer, Stronger Metals for Your Applications

- How does a vertical vacuum furnace facilitate MgB2 wire fabrication? Master Internal Magnesium Coating Processes