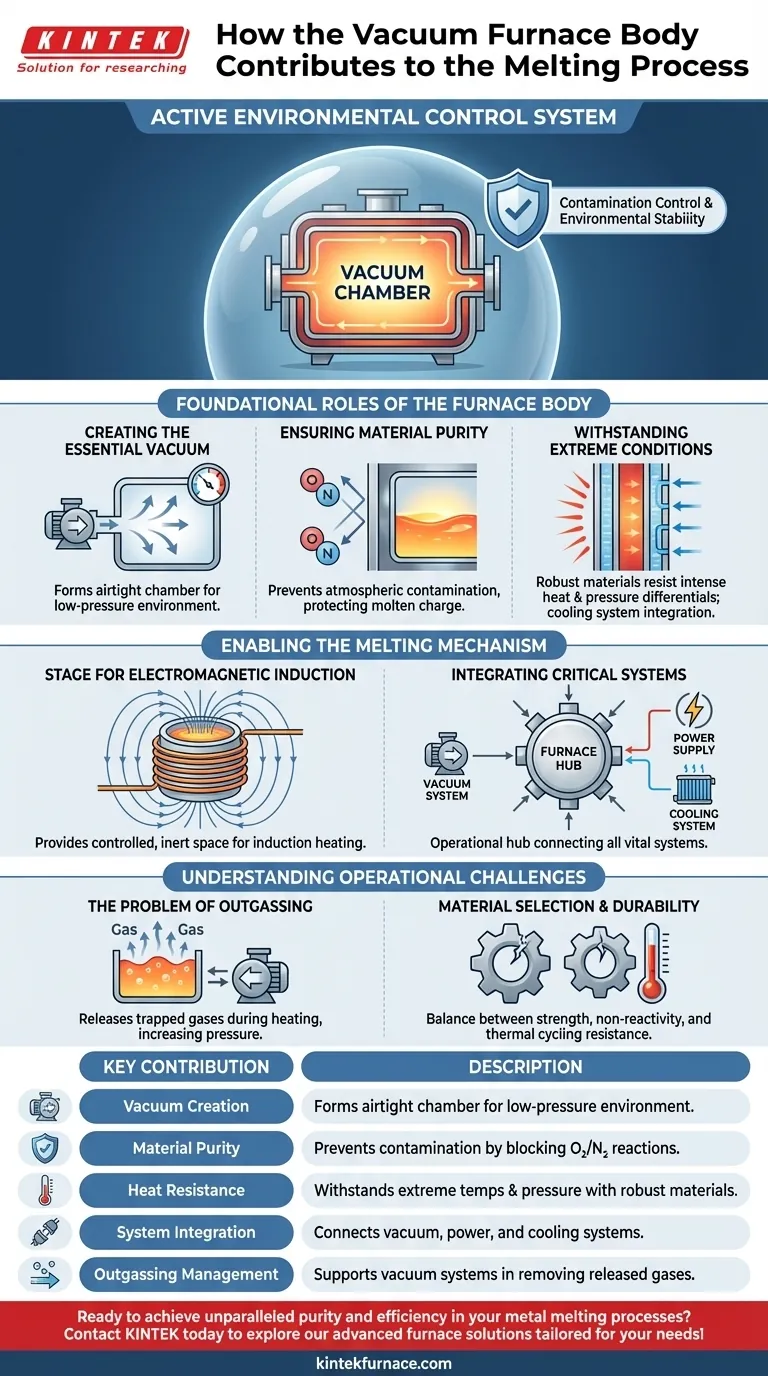

At its core, the vacuum furnace body is far more than a simple container. It is an active environmental control system that creates and maintains the pristine, airtight vacuum chamber essential for the melting process. By withstanding extreme temperatures and preventing atmospheric contamination, the body enables the production of high-purity materials that would otherwise be impossible to create.

The furnace body does not generate the heat for melting; rather, it creates the isolated, ultra-clean environment required for the induction heating process to work effectively. Its primary contribution is contamination control and environmental stability, which is the cornerstone of vacuum metallurgy.

The Foundational Roles of the Furnace Body

The furnace body serves as the physical foundation upon which the entire vacuum melting process is built. Its design directly impacts the quality of the final product.

Creating the Essential Vacuum

The most fundamental role of the furnace body is to form an airtight chamber. This sealed enclosure allows the connected vacuum system to pump out air and other gases, creating the low-pressure environment that defines the process.

Without a perfectly sealed body, a sufficient vacuum cannot be achieved or maintained.

Ensuring Material Purity

This vacuum environment is critical for preventing atmospheric contamination. Elements like oxygen and nitrogen in the air can react aggressively with molten metals, forming oxides and nitrides that compromise the material's integrity.

The furnace body acts as a barrier, protecting the molten charge from these unwanted reactions and ensuring the production of clean, high-purity alloys.

Withstanding Extreme Conditions

The body is constructed from robust, high-temperature-resistant materials like stainless steel. It must endure the intense heat radiating from the melt and the immense pressure differential between the internal vacuum and the outside atmosphere.

Furthermore, furnace bodies are often integrated with a cooling system, typically using water jackets, to manage their temperature and prevent structural failure during prolonged, high-heat operations.

How the Body Enables the Melting Mechanism

While the furnace body is not the source of heat, it is the stage where the melting occurs and the hub that connects all critical systems.

A Stage for Electromagnetic Induction

The actual melting is performed by electromagnetic induction, where a powerful alternating current in a coil generates a magnetic field. This field induces eddy currents within the metallic charge, and the material's own electrical resistance generates intense heat, causing it to melt.

The furnace body provides the controlled, inert space where this can happen without the metal reacting with outside air.

Integrating with Critical Systems

The body is the central structure that unites the furnace's various components. It features ports for the vacuum system, insulated feedthroughs for the power supply that energizes the induction coil, and connections for the cooling system.

This integration makes the body the operational hub of the furnace, physically connecting every system required for a successful melt.

Understanding Operational Challenges

The furnace body's role is not without its difficulties. Its design must account for inherent physical challenges that arise during operation.

The Problem of Outgassing

During the heating cycle, the raw materials being melted, and even the internal furnace components themselves, release trapped gases in a process called outgassing.

This phenomenon works against the vacuum system, increasing the pressure inside the chamber. A high-performance vacuum system, coupled with a properly sealed body, is essential to pump away these gases and maintain the desired vacuum level.

Material Selection and Durability

The choice of material for the furnace body, such as stainless steel, involves critical trade-offs. The material must be strong enough to resist vacuum pressure, non-reactive with the process, and capable of withstanding constant thermal cycling without warping or cracking.

This balance between performance, cost, and operational lifespan is a key consideration in furnace design and maintenance.

Applying This to Your Goal

Understanding the function of the furnace body helps you prioritize different aspects of the vacuum melting process based on your objective.

- If your primary focus is producing high-purity reactive alloys (like titanium or superalloys): The furnace body's ability to maintain a deep, contaminant-free vacuum is its most critical function.

- If your primary focus is process efficiency and consistency: The body's seamless integration with the cooling and vacuum systems is key to achieving stable, repeatable melting cycles.

- If your primary focus is equipment longevity and maintenance: The construction materials and design of the furnace body directly determine its resistance to thermal stress and its overall operational lifespan.

Ultimately, viewing the furnace body as the foundation of environmental control is the key to mastering the vacuum melting process.

Summary Table:

| Key Contribution | Description |

|---|---|

| Vacuum Creation | Forms an airtight chamber for low-pressure environment, essential for melting. |

| Material Purity | Prevents atmospheric contamination by blocking oxygen and nitrogen reactions. |

| Heat Resistance | Withstands extreme temperatures and pressure differentials with robust materials. |

| System Integration | Connects vacuum, power, and cooling systems for efficient operation. |

| Outgassing Management | Supports vacuum systems in removing gases released during heating for stability. |

Ready to achieve unparalleled purity and efficiency in your metal melting processes? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored for diverse laboratories. With our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring contamination control, durability, and seamless system integration. Contact us today to explore how our expertise can elevate your production goals!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications