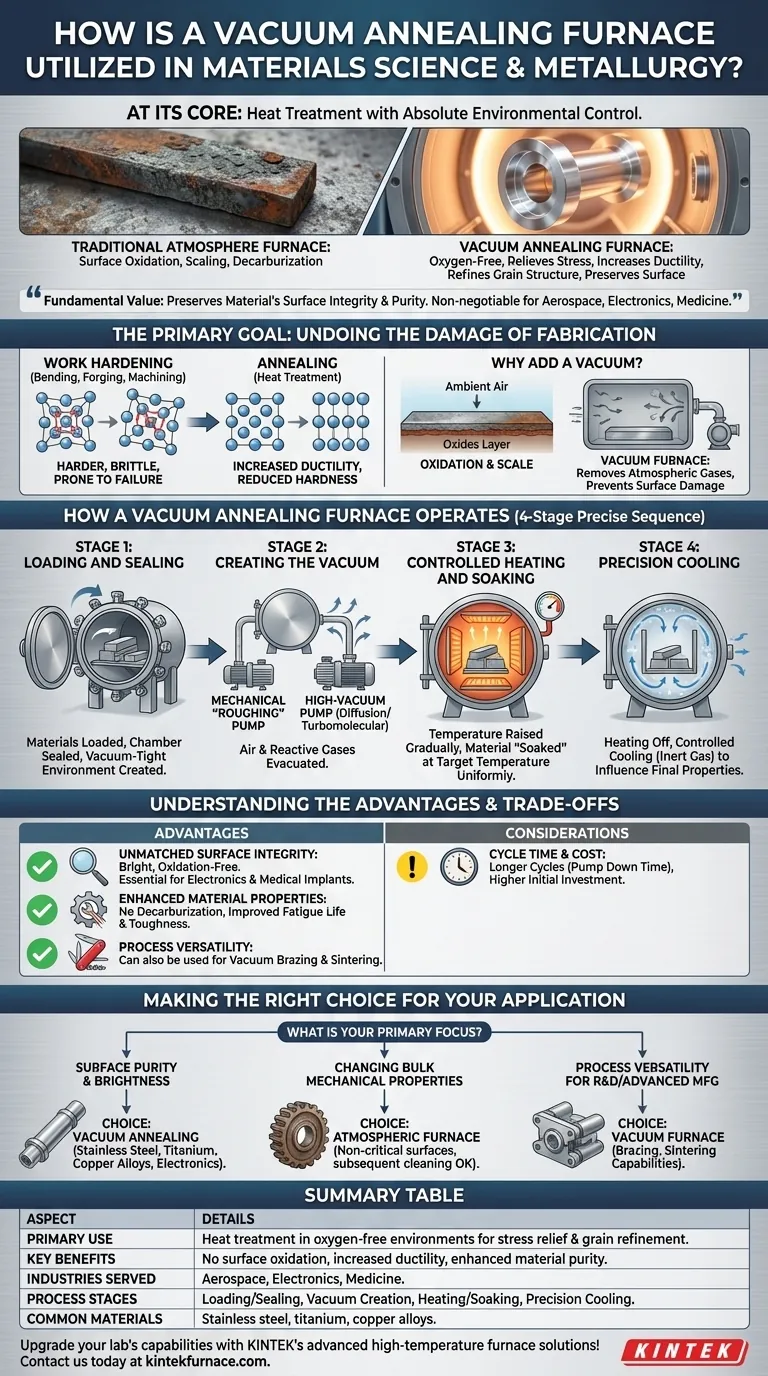

At its core, a vacuum annealing furnace is used in materials science and metallurgy to heat materials in an oxygen-free environment. This process relieves internal stresses, increases ductility, and refines the material’s grain structure without causing the surface oxidation, scaling, or decarburization that occurs in traditional atmosphere furnaces.

The fundamental value of vacuum annealing is not just heat treatment, but heat treatment with absolute environmental control. This preserves the material's surface integrity and purity, which is non-negotiable for high-performance applications in aerospace, electronics, and medicine.

The Primary Goal: Undoing the Damage of Fabrication

Any time a metal is bent, forged, machined, or drawn, it undergoes a process called work hardening. This introduces significant internal stress, making the material harder but also more brittle and prone to failure.

What is Annealing?

Annealing is a heat treatment process that reverses the effects of work hardening. By heating a material to a specific temperature and holding it there, the atoms within its crystal structure can rearrange into a more stable, stress-free state.

This controlled thermal cycle fundamentally changes the material's mechanical properties, primarily increasing its ductility (ability to deform without fracturing) and reducing its hardness.

Why Add a Vacuum?

Heating metal in the presence of oxygen, even in the small amounts found in ambient air, causes oxidation. This creates a layer of scale on the surface that is often undesirable, requires secondary cleaning processes, and can compromise the dimensions of a precision part.

A vacuum furnace removes virtually all atmospheric gases from the chamber before heating begins. This protective, inert environment ensures the material's surface remains bright, clean, and chemically unchanged throughout the process.

How a Vacuum Annealing Furnace Operates

The process is a precise, multi-stage sequence designed for repeatability and control. Each stage is critical to achieving the desired material properties.

Stage 1: Loading and Sealing

Materials are loaded into the furnace chamber. The door is then sealed to create a vacuum-tight environment, isolating the interior from the outside atmosphere.

Stage 2: Creating the Vacuum

A system of pumps, typically a combination of a mechanical "roughing" pump and a high-vacuum pump (like a diffusion or turbomolecular pump), evacuates the air from the chamber. This removes the oxygen and other reactive gases.

Stage 3: Controlled Heating and Soaking

Once the target vacuum level is reached, heaters inside the furnace gradually raise the material's temperature at a controlled rate. The material is then "soaked" by holding it at the target annealing temperature for a specific duration to ensure the entire part is heated uniformly.

Stage 4: Precision Cooling

After soaking, the heating elements are turned off. The material cools down, often through controlled means such as forced cooling with an inert gas like nitrogen or argon. The cooling rate is a critical variable that influences the final microstructure and properties of the material.

Understanding the Advantages and Trade-offs

While highly effective, vacuum annealing involves a distinct set of benefits and considerations compared to other heat treatment methods.

Advantage: Unmatched Surface Integrity

The most significant benefit is a clean, bright, oxidation-free surface. This is essential for electronic components where surface chemistry is critical, or for medical implants where purity is paramount.

Advantage: Enhanced Material Properties

The oxygen-free environment prevents surface decarburization in steels, which can weaken the material. The result is improved and more consistent mechanical properties, such as fatigue life and toughness.

Advantage: Process Versatility

Many vacuum furnaces are not limited to annealing. The same equipment can often be used for other thermal processes that benefit from a controlled atmosphere, such as vacuum brazing (joining materials) and sintering (fusing powders).

Consideration: Cycle Time and Cost

Vacuum furnace cycles are generally longer than conventional furnace cycles due to the time required to pump down the chamber. The equipment is also more complex and represents a higher initial capital investment.

Making the Right Choice for Your Application

Selecting the right thermal process depends entirely on your end goal and material requirements.

- If your primary focus is surface purity and brightness: Vacuum annealing is the definitive choice, especially for stainless steel, titanium, copper alloys, and electronic components.

- If your primary focus is changing bulk mechanical properties on non-critical surfaces: A less expensive atmospheric furnace may be sufficient, provided you can accommodate subsequent surface cleaning.

- If your primary focus is process versatility for R&D or advanced manufacturing: A vacuum furnace's ability to also perform brazing and sintering provides significant long-term value.

Ultimately, vacuum annealing is the standard for applications where material performance and surface quality cannot be compromised.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Use | Heat treatment in oxygen-free environments for stress relief and grain refinement |

| Key Benefits | No surface oxidation, increased ductility, enhanced material purity |

| Industries Served | Aerospace, electronics, medicine |

| Process Stages | Loading/sealing, vacuum creation, heating/soaking, precision cooling |

| Common Materials | Stainless steel, titanium, copper alloys |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum annealing furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing material purity and performance in your applications. Contact us today to discuss how we can support your projects and deliver tailored solutions!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today