A three-electrode batch electric melting furnace acts as a critical thermal bridge, supplying external energy when chemical reactions are insufficient to sustain themselves. Specifically, it compensates for the low heat output during the initial reduction of oxides, ultimately reducing specific energy consumption by 22 to 128 kWh per kilogram of product.

Core Takeaway: The furnace does not merely melt material; it actively balances the thermodynamic inefficiencies of the alumino-hydrogen process by jumpstarting weakly exothermic reactions and enabling the recovery of heat generated in later stages.

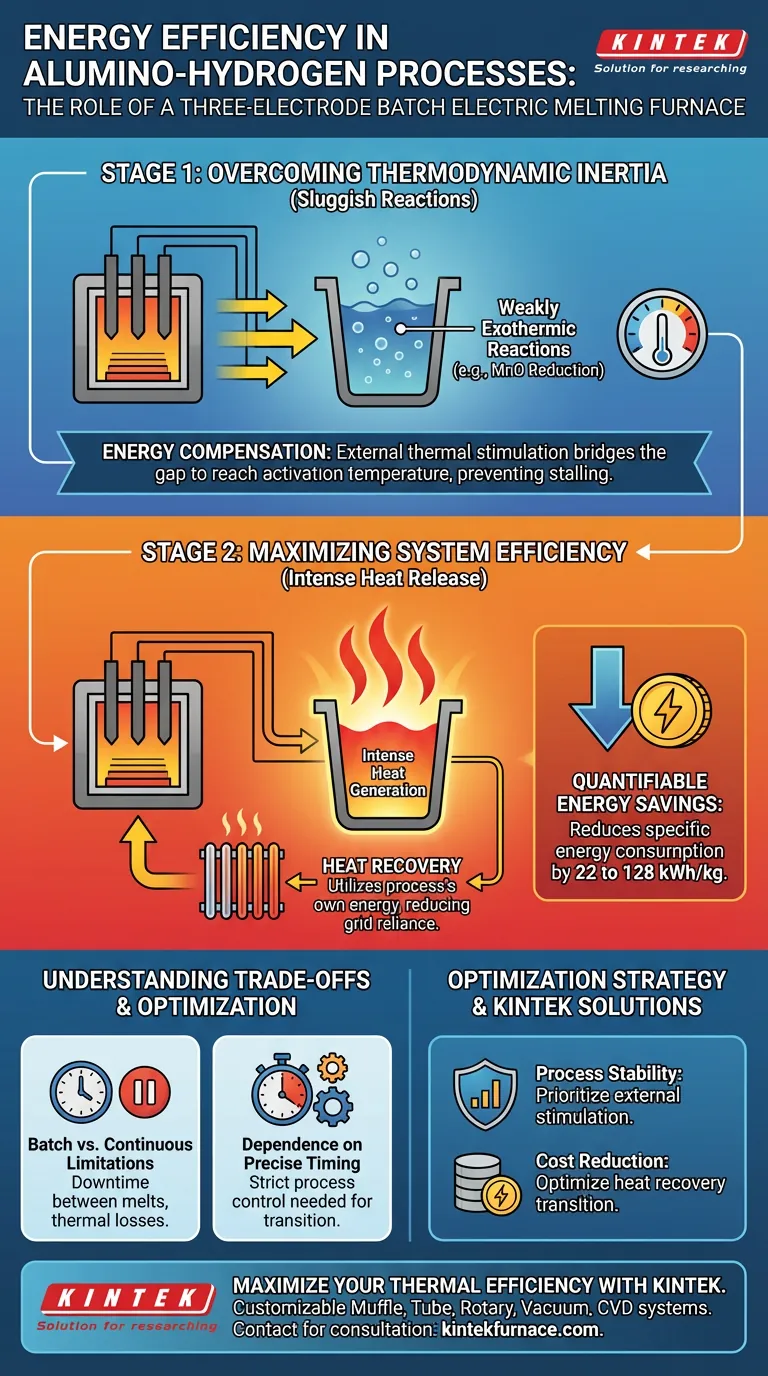

Overcoming Thermodynamic Inertia

Stimulating Weak Reactions

The primary challenge in combined alumino-hydrogen thermal reduction is that early reaction stages are often chemically sluggish.

The reduction of specific components, such as manganese oxides to MnO, is weakly exothermic.

Without external intervention, these reactions lack the naturally occurring thermal energy required to propagate effectively.

The Role of the Three-Electrode System

The electric furnace provides the necessary energy compensation to bridge this thermodynamic gap.

By applying external thermal stimulation, the furnace ensures the process reaches the necessary activation temperatures during the aluminothermic stage.

This prevents the reaction from stalling due to insufficient heat generation.

Maximizing System Efficiency

Facilitating Heat Recovery

Once the reaction moves past the initial sluggish stage, subsequent chemical interactions release intense heat.

The furnace infrastructure is not just an input device; it is designed to coordinate with this thermal shift.

This coordination allows the system to utilize the process's own generated energy rather than relying solely on the electrical grid for the duration of the cycle.

Quantifiable Energy Savings

The impact of this thermal management is measurable and significant.

By optimizing the heating cycle to match the reaction's needs, specific energy consumption drops by 22 to 128 kWh per kilogram.

This represents a massive improvement in overall energy utilization for the production line.

Understanding the Trade-offs

Batch vs. Continuous Limitations

While efficient per cycle, this is specifically a batch electric melting furnace.

This implies inherent downtime between melts for loading and discharging, which can impact overall throughput compared to fully continuous systems.

The energy savings during the melt must be weighed against the thermal losses that occur while the furnace is idle between batches.

Dependence on Precise Timing

The efficiency of this system relies heavily on "equipment coordination."

If the external heat is applied too long, electricity is wasted; if applied too briefly, the reaction stalls.

Operators must maintain strict process control to ensure the transition from external heating to internal heat recovery happens at the exact thermodynamic tipping point.

Optimizing Production Strategy

To maximize the benefits of this furnace setup, align your operational goals with the equipment's strengths.

- If your primary focus is process stability: Prioritize the furnace's ability to provide external stimulation during the volatile early reduction stages to prevent reaction failure.

- If your primary focus is cost reduction: Focus on optimizing the transition point to the heat recovery phase to hit the upper range of the 128 kWh/kg savings potential.

The three-electrode furnace transforms the alumino-hydrogen process from a thermally disjointed reaction into a cohesive, energy-efficient cycle.

Summary Table:

| Feature | Impact on Efficiency | Benefit |

|---|---|---|

| Energy Compensation | Stimulates weakly exothermic reactions | Prevents process stalling in early stages |

| Heat Recovery | Captures heat from intense later stages | Reduces reliance on external electrical grid |

| Thermal Management | Cuts 22–128 kWh/kg of specific energy | Significant reduction in production costs |

| Process Control | Balances thermodynamic inertia | Ensures stable, cohesive reaction cycles |

Maximize Your Thermal Efficiency with KINTEK

Are you looking to optimize your reduction processes and slash specific energy consumption? KINTEK provides the cutting-edge thermal technology your lab or production facility needs.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temperature furnaces—all fully customizable to meet your unique thermodynamic requirements. Whether you are balancing weak exothermic reactions or seeking advanced heat recovery, our solutions ensure precision and stability.

Take control of your production costs today. Contact KINTEK for a custom consultation and let our experts design the perfect furnace system for your unique application.

Visual Guide

References

- Gigo Jandieri, Giorgi Sakhvadze. Hydrated aluminum powder for direct alloying of steel and alloys - challenges of the future. DOI: 10.51582/interconf.19-20.03.2024.044

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a vacuum non-consumable arc furnace play in high-entropy alloys? Master Complex Alloy Synthesis

- What is a Vacuum Induction Melting Furnace and where is it commonly used? Unlock High-Purity Alloy Production

- How does induction heating contribute to pyrolysis? Unlock Precision and Efficiency in Biomass Processing

- Why is repeated melting necessary for AlCoCrFeNi2.1 HEA? Achieving Chemical Uniformity in High-Entropy Alloys

- Why is precise temperature control important in induction furnaces? Achieve Metallurgical Excellence

- What are the advantages of an IGBT induction melting furnace? Boost Efficiency & Productivity

- Why use vacuum arc furnaces and copper mold suction casting for Ti-xNb alloys? Key to Biomedical Material Excellence

- What is a resonant tank circuit and how is it used in the described induction heater? Boost Efficiency with Energy Oscillation