In metallurgy and advanced manufacturing, a Vacuum Induction Melting (VIM) furnace is specialized equipment that uses electromagnetic induction to melt and refine metals within a high-vacuum environment. This process is not merely for melting; it is a sophisticated refining technique essential for creating the high-purity, high-performance alloys and superalloys demanded by industries like aerospace, biomedical, and high-performance electronics.

The core value of a VIM furnace is not just its ability to melt metal, but its power to control the material's fundamental chemistry. By removing the atmosphere, it eliminates contamination and allows for the production of exceptionally pure, homogenous alloys that are impossible to create using conventional methods.

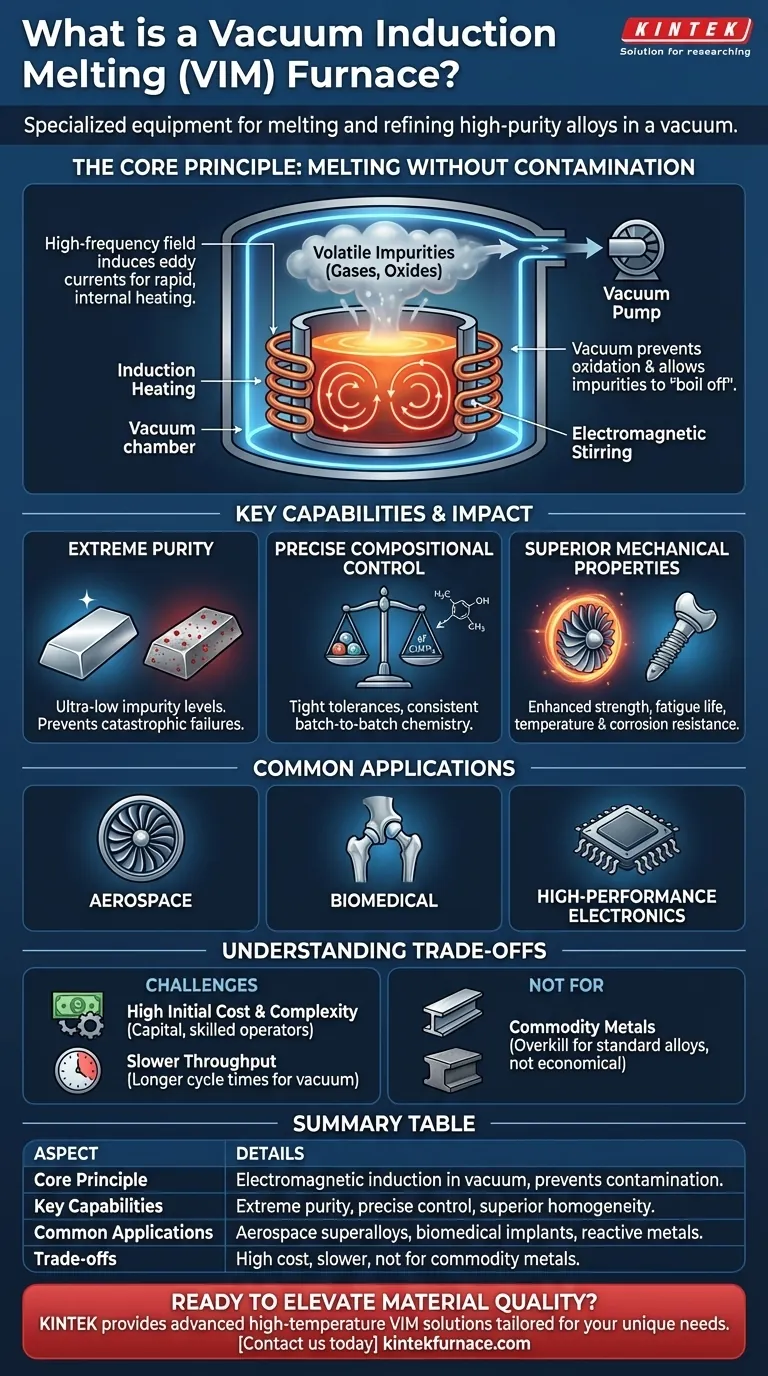

The Core Principle: Melting Without Contamination

At its heart, the VIM process solves one of the oldest problems in metallurgy: the unwanted reactions that occur when molten metal is exposed to air. Oxygen and nitrogen in the atmosphere readily react with hot metals, creating impurities (oxides and nitrides) that degrade the final material's properties.

How Induction Heating Works

A VIM furnace does not use flames or external heating elements. Instead, it generates a powerful, high-frequency electromagnetic field around a crucible containing the metal charge. This field induces strong electrical eddy currents within the metal itself, and the metal's natural electrical resistance causes it to heat up rapidly and melt from the inside out.

The Critical Role of the Vacuum

The entire process takes place inside a sealed chamber from which the air has been removed. This vacuum environment is fundamental to the furnace's capabilities. It prevents oxidation because there is no oxygen to react with the molten metal.

Furthermore, the low-pressure environment allows dissolved gases like hydrogen and nitrogen, along with other volatile, low-boiling-point impurities, to "boil off" and be removed from the melt.

Achieving Unmatched Homogeneity

The same electromagnetic field that heats the metal also creates a natural, vigorous stirring action within the molten bath. This electromagnetic stirring is crucial for ensuring that all alloying elements are distributed perfectly evenly, preventing segregation and resulting in a completely homogenous final product.

Key Capabilities and Their Impact

The unique combination of induction heating and a vacuum environment gives VIM furnaces capabilities that directly translate to superior material quality.

Extreme Purity

By preventing oxidation and removing dissolved gases and volatile trace elements, VIM produces metals with extremely low levels of impurities. This is critical for materials where even parts-per-million contamination can cause catastrophic failure.

Precise Compositional Control

With the base metal melted in a clean environment, metallurgists can introduce precise amounts of alloying elements. Because there are no unpredictable reactions with air, the final chemical composition can be controlled with exceptionally tight tolerances, ensuring batch-to-batch consistency.

Superior Mechanical Properties

The resulting purity and homogeneity directly lead to materials with enhanced properties. These include greater strength, improved fatigue life, higher temperature resistance, and superior corrosion resistance—all essential for high-stress, critical applications.

Understanding the Trade-offs

While powerful, VIM technology is a specialized tool with specific trade-offs that make it unsuitable for every application.

High Initial Cost and Complexity

VIM furnaces are sophisticated systems that involve vacuum pumps, high-power electrical supplies, and complex control systems. This results in a significantly higher capital investment and requires more highly skilled operators compared to conventional air-melt furnaces.

Slower Throughput

The operational cycle includes the time required to pump the chamber down to a deep vacuum and, in many cases, backfill it with an inert gas like argon. This makes the overall batch cycle time longer than for simple air-melting processes.

Overkill for Commodity Metals

For applications involving standard-grade steels, cast iron, or general-purpose aluminum where absolute purity is not the primary concern, VIM is an unnecessary expense. The cost outweighs the benefits, and simpler, higher-volume melting methods are far more economical.

Making the Right Choice for Your Application

Selecting the right melting technology depends entirely on the performance requirements of your final product. VIM is the solution when material integrity cannot be compromised.

- If your primary focus is producing high-performance superalloys or reactive metals: VIM is the industry standard for achieving the required purity, strength, and temperature resistance for applications like jet engine turbine blades.

- If your primary focus is manufacturing medical implants or high-purity electronics: The absolute cleanliness and precise compositional control of the VIM process are non-negotiable to ensure biocompatibility and reliable performance.

- If your primary focus is high-volume, low-cost casting of standard alloys: VIM is likely overkill, and more cost-effective technologies like conventional induction or electric arc furnaces are the appropriate choice.

Ultimately, adopting VIM technology is a strategic decision to gain absolute control over material chemistry at the highest level of precision.

Summary Table:

| Aspect | Details |

|---|---|

| Core Principle | Uses electromagnetic induction in a vacuum to melt metals, preventing contamination and removing impurities. |

| Key Capabilities | Extreme purity, precise compositional control, superior homogeneity, and enhanced mechanical properties. |

| Common Applications | Aerospace superalloys, biomedical implants, high-performance electronics, and reactive metals. |

| Trade-offs | High initial cost, slower throughput, and not suitable for commodity metals due to complexity. |

Ready to elevate your material quality with precision melting solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored for industries like aerospace and biomedical. Our deep customization capabilities ensure we meet your unique experimental needs. Contact us today to discuss how our expertise can enhance your alloy production and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control