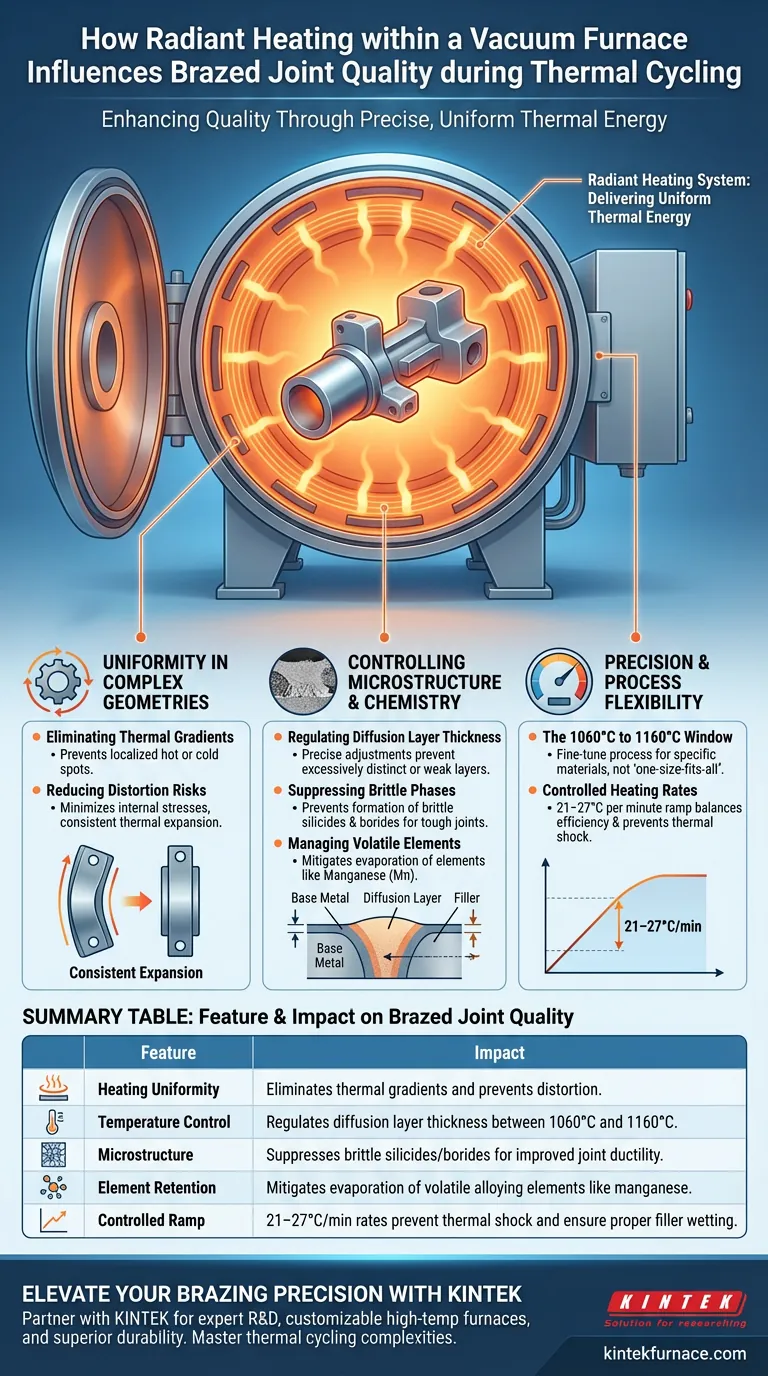

Radiant heating systems significantly enhance brazed joint quality by delivering precise, uniform thermal energy to components, even those with complex geometries. By enabling controlled heating rates of typically 21–27°C per minute, this method ensures microstructural stability and prevents the formation of defects that compromise joint integrity during thermal cycling.

By maintaining strict temperature control between 1060°C and 1160°C, radiant heating regulates the diffusion layer thickness and suppresses the precipitation of brittle phases. This precision is the defining factor in preventing element evaporation and ensuring a ductile, durable bond.

The Role of Uniformity in Complex Geometries

Eliminating Thermal Gradients

Radiant heating provides a stable thermal environment that surrounds the component. This ensures that parts with complex geometries heat evenly from all sides, rather than suffering from localized hot or cold spots.

Reducing Distortion Risks

When heating is uniform, the thermal expansion across the component remains consistent. This minimizes the internal stresses that often lead to distortion or warping during the brazing cycle.

Controlling Microstructure and Chemistry

Regulating Diffusion Layer Thickness

The strength of a brazed joint relies heavily on the diffusion layer between the base metal and the filler. Radiant heating allows for precise temperature adjustments that regulate the thickness of this layer, preventing it from becoming too distinct or weak.

Suppressing Brittle Phases

A major cause of joint failure is the precipitation of brittle intermetallics. Precise thermal control effectively suppresses the formation of brittle silicides and borides, ensuring the joint remains tough rather than fragile.

Managing Volatile Elements

Certain alloying elements, such as manganese, are prone to evaporation under high heat and vacuum. The control offered by radiant systems mitigates this loss, preserving the chemical composition and intended properties of the brazing alloy.

Precision and Process Flexibility

The 1060°C to 1160°C Window

Radiant systems offer exceptional flexibility within the critical brazing range of 1060°C and 1160°C. This adjustability allows operators to fine-tune the process for specific materials rather than relying on a "one-size-fits-all" approach.

Controlled Heating Rates

The ability to maintain a heating rate of 21–27°C per minute provides a balance between efficiency and thermal shock prevention. This controlled ramp-up is essential for allowing the brazing filler metal to flow and wet the surface properly without degradation.

Understanding the Trade-offs

Cycle Time vs. Quality

While a rate of 21–27°C per minute ensures high quality, it is a deliberate process. This method prioritizes microstructural integrity over rapid throughput, potentially extending cycle times compared to less precise heating methods.

Process Sensitivity

The flexibility to adjust temperatures between 1060°C and 1160°C requires precise process development. Operators must determine the exact parameters to balance diffusion thickness against element evaporation, as slight deviations can alter the joint's mechanical properties.

Optimizing Your Brazing Strategy

To leverage radiant heating effectively, align your process parameters with your specific component needs:

- If your primary focus is Geometric Complexity: Utilize the uniform heating distribution to minimize distortion in parts with intricate shapes or varying cross-sections.

- If your primary focus is Joint Ductility: Target the suppression of silicides and borides by strictly controlling the dwell time and temperature within the 1060°C–1160°C range.

- If your primary focus is Alloy Integrity: Monitor the vacuum and temperature ramp rates to prevent the evaporation of volatile elements like manganese.

Precise thermal management is the difference between a joint that survives thermal cycling and one that fails prematurely.

Summary Table:

| Feature | Impact on Brazed Joint Quality |

|---|---|

| Heating Uniformity | Eliminates thermal gradients and prevents distortion in complex geometries. |

| Temperature Control | Regulates diffusion layer thickness between 1060°C and 1160°C. |

| Microstructure | Suppresses brittle silicides/borides for improved joint ductility. |

| Element Retention | Mitigates evaporation of volatile alloying elements like manganese. |

| Controlled Ramp | 21–27°C/min rates prevent thermal shock and ensure proper filler wetting. |

Elevate Your Brazing Precision with KINTEK

Don't let thermal instability compromise your critical components. KINTEK provides industry-leading vacuum furnace solutions designed to master the complexities of thermal cycling.

Why partner with KINTEK?

- Expert R&D: Access advanced thermal processing insights for complex geometries.

- Customizable Systems: From Muffle and Tube to Vacuum and CVD systems, we tailor our high-temp furnaces to your exact specifications.

- Superior Durability: Ensure ductile, reliable bonds that resist brittle phase formation.

Ready to optimize your thermal management strategy? Contact our expert team today to discover how our customizable lab furnaces can transform your manufacturing outcomes.

Visual Guide

References

- S.V. Maksymova, P.V. Kovalchuk. Brazing stainless steel with high chromium nickel alloy. DOI: 10.21203/rs.3.rs-7259392/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the primary functions of an industrial-grade vacuum furnace? Optimize Magnet Recycling Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the applications of high-temperature vacuum sintering furnaces? Essential for Aerospace, Electronics, and Medical Materials

- What features contribute to the high degree of electromechanical integration in a vacuum furnace? Unlock Precision and Automation

- What role does an industrial-grade vacuum sintering furnace play in the final molding of 17-4 PH stainless steel parts?

- What are the primary functions of a laboratory drying oven in banana peel activated carbon? Optimize Every Process Step

- How should a crucible be handled after being heated in a vacuum furnace? Ensure Material Integrity & Accurate Results

- How does optimizing the graphite base material improve the quality of cemented carbide sintering? Master Thermal Uniformity