An industrial-grade vacuum sintering furnace acts as the critical vessel for transforming a fragile, binder-laden preform into a solid, high-performance metal component. It operates at specific high temperatures, such as 1310°C, to thermally decompose residual binders like High-Density Polyethylene (HDPE) while simultaneously fusing metal particles through atomic diffusion. This process solidifies the shape, prevents oxidation, and densifies the material to near-theoretical limits.

The vacuum sintering furnace is not merely an oven; it is a controlled environment that manages the transition from a "green" or "brown" part to a finished metal alloy. It bridges the gap between molding and final application by eliminating contaminants and locking in mechanical properties.

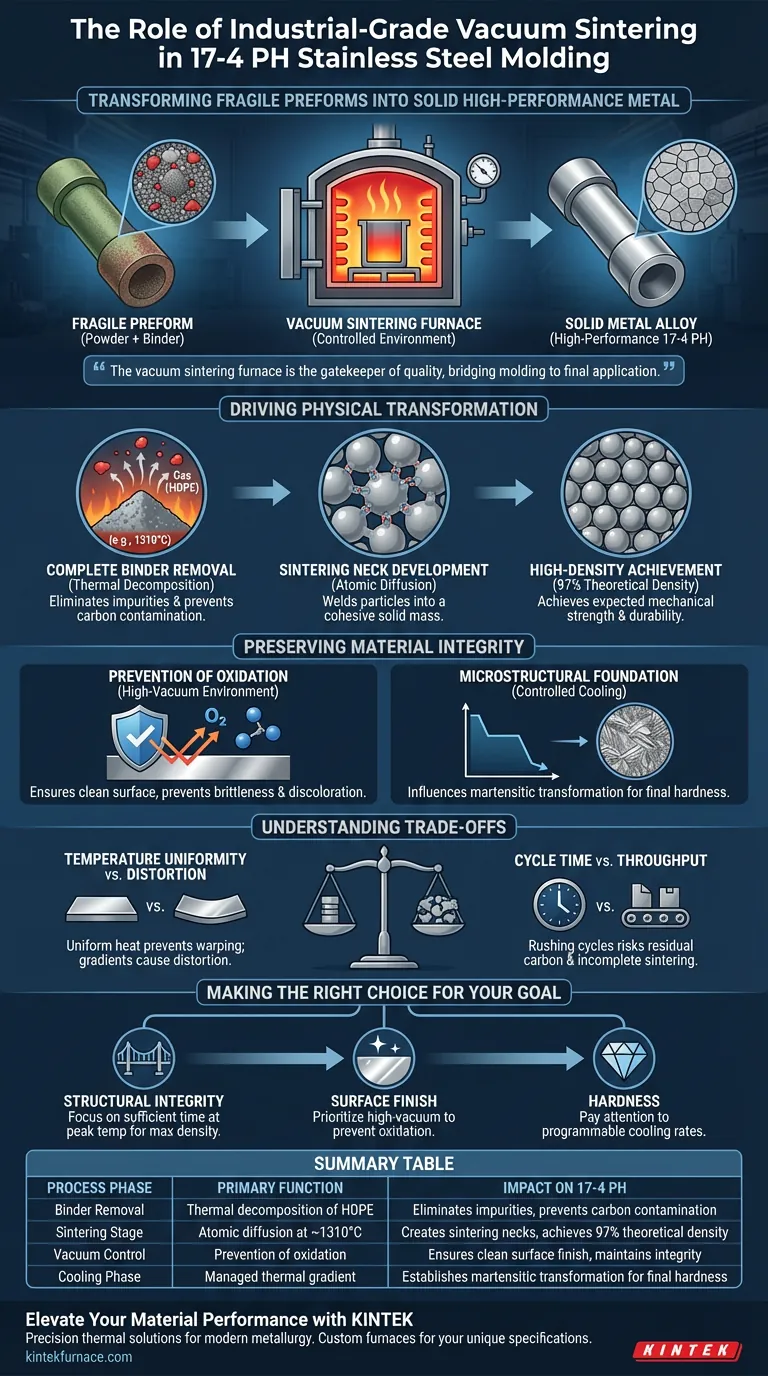

Driving Physical Transformation

To understand the furnace's role in "final molding" (more accurately termed densification or sintering), one must look at the atomic changes occurring within the chamber.

Complete Binder Removal

Before the steel particles can fuse, the remaining binding agents must be evacuated.

The furnace uses high heat to trigger the thermal decomposition of residual binders, such as High-Density Polyethylene (HDPE). This ensures that no non-metallic impurities remain within the internal structure of the part.

Sintering Neck Development

Once the binder is removed, the furnace facilitates atomic diffusion.

At elevated temperatures, the metal particles begin to bond at their contact points. This creates "sintering necks," effectively welding the individual particles together into a cohesive solid mass.

High-Density Achievement

The ultimate goal of this thermal cycle is densification.

Through controlled heating, the furnace enables the 17-4 PH parts to reach up to 97% of their theoretical density. This reduction in porosity is essential for achieving the material's expected mechanical strength and durability.

Preserving Material Integrity

17-4 PH stainless steel is sensitive to its environment. The "vacuum" aspect of the furnace is just as critical as the heat.

Prevention of Oxidation

Stainless steel contains elements that can easily react with oxygen at high temperatures.

The high-vacuum environment actively prevents oxidation during the sintering process. This ensures the final parts maintain a clean surface and superior mechanical properties, rather than becoming brittle or discolored due to oxide formation.

Microstructural Foundation

The cooling phase within the furnace sets the stage for the metal's final hardness.

Precise control over the cooling rate influences the martensitic transformation of the steel. This thermal management establishes the microstructural baseline required for any subsequent precipitation hardening or aging treatments.

Understanding the Trade-offs

While vacuum sintering is powerful, it requires precise calibration to avoid common manufacturing pitfalls.

Temperature Uniformity vs. Distortion

Ideally, the furnace provides uniform heat to ensure even shrinkage. However, if thermal gradients exist, parts may warp or distort during densification, compromising dimensional accuracy.

Cycle Time vs. Throughput

Achieving 97% density and ensuring complete binder removal takes time. Rushing the heating or cooling cycles to increase production speed can lead to residual carbon contamination or incomplete sintering, resulting in parts with inferior fatigue life.

Making the Right Choice for Your Goal

The vacuum sintering furnace is the gatekeeper of quality for 17-4 PH parts. How you utilize it depends on your specific performance requirements.

- If your primary focus is Structural Integrity: Ensure the furnace cycle allows sufficient time at peak temperature (e.g., 1310°C) to maximize atomic diffusion and achieve the highest possible density.

- If your primary focus is Surface Finish: Prioritize a high-vacuum environment to rigorously prevent oxidation, ensuring the part emerges clean and ready for electrochemical testing or polishing.

- If your primary focus is Hardness: Pay close attention to the programmable cooling rates to correctly influence the martensitic transformation, setting the stage for effective precipitation hardening later.

The vacuum sintering furnace transforms a mixture of powder and plastic into a durable engineering marvel by mastering the balance between heat, vacuum, and time.

Summary Table:

| Process Phase | Primary Function | Impact on 17-4 PH Stainless Steel |

|---|---|---|

| Binder Removal | Thermal decomposition of HDPE | Eliminates impurities and prevents carbon contamination |

| Sintering Stage | Atomic diffusion at ~1310°C | Creates sintering necks and achieves 97% theoretical density |

| Vacuum Control | Prevention of oxidation | Ensures clean surface finish and maintains material integrity |

| Cooling Phase | Managed thermal gradient | Establishes martensitic transformation for final hardness |

Elevate Your Material Performance with KINTEK

Precision is non-negotiable when sintering 17-4 PH stainless steel. KINTEK provides industry-leading thermal solutions designed to meet the rigorous demands of modern metallurgy. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temp furnaces—all fully customizable to your unique specifications.

Whether you need to achieve near-theoretical density or ensure a perfect oxide-free finish, our technical experts are ready to help you optimize your process.

Contact KINTEK today to discuss your custom furnace needs.

Visual Guide

References

- Development of 17-4 PH Stainless Steel for Low-Power Selective Laser Sintering. DOI: 10.3390/ma18020447

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a vacuum chamber during the TLP bonding process? Achieve High-Purity Defect-Free Joints

- What are the environmental requirements for vacuum sintering? Achieve Superior Material Density and Purity

- How does a vacuum distillation system function in REE extraction? Master LME Separation with Precision

- Why is a high-purity quartz tube used for vacuum sealing NbTaTiV alloys? Ensure Purity & Prevent Embrittlement

- Why is a high vacuum level required for a thermal evaporator? Ensure Pure Transition Metal Oxide (TMO) Deposition

- What are the advantages of a vertical vacuum furnace for heat treating parts with increased structure? Achieve Superior Uniformity and Minimal Distortion

- How does a high vacuum annealing furnace contribute to 2D Bi2Te3-Sb2Te3 superlattices? Precision Thermal Engineering

- What is the necessity of using a vacuum chamber before curing epoxy? Eliminate Defects for Superior Material Integrity