For heat treating parts with complex structures, a vertical vacuum furnace provides a decisive advantage by ensuring superior temperature uniformity and minimizing distortion. Its design is engineered to handle geometrically challenging or vertically stackable components, delivering consistent metallurgical properties even under high load densities and for parts with intricate cross-sections.

The core challenge with complex parts isn't just heating them, but heating and cooling them perfectly evenly to prevent warping and internal stress. A vertical furnace's orientation naturally promotes uniform gas flow and stable part positioning, directly addressing this fundamental problem.

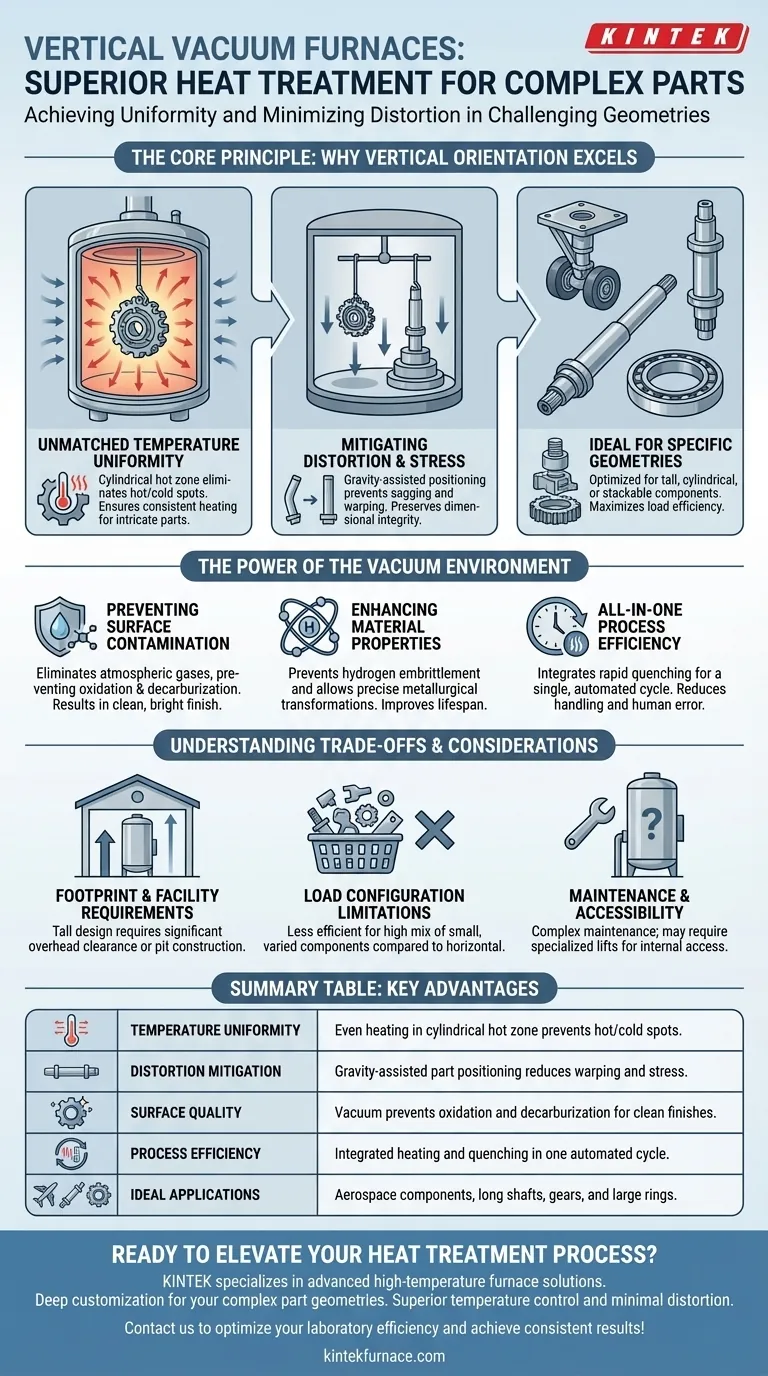

The Core Principle: Why Vertical Orientation Excels

The primary benefit of a vertical furnace is not just the vacuum environment, but the physical orientation of the heating chamber itself. This design directly counters common issues faced when treating complex or sensitive components.

Unmatched Temperature Uniformity

A cylindrical, vertical hot zone promotes exceptionally uniform heating. Convective gas flow and radiant heat are distributed more evenly around the load, eliminating the hot and cold spots that can occur in other configurations.

This is critical for parts with varying thicknesses or complex geometries, ensuring the entire component reaches the target temperature at the same rate.

Mitigating Distortion and Stress

Parts can be hung from fixtures or stacked stably on the furnace base. This orientation uses gravity to its advantage, preventing the sagging, bending, or warping that can occur when long or delicate parts are laid horizontally.

By minimizing thermal stress during rapid heating and quenching cycles, the vertical design preserves the part's dimensional integrity.

Ideal for Specific Geometries

This furnace configuration is purpose-built for parts with cylindrical cross-sections or those that can be efficiently stacked.

Common examples include aerospace landing gear components, long shafts, gears, and large bearing rings. The vertical layout maximizes load efficiency for these specific shapes.

The Power of the Vacuum Environment

While the vertical orientation is key, the vacuum environment provides foundational benefits that are essential for producing high-quality, high-performance parts.

Preventing Surface Contamination

Operating in a vacuum eliminates atmospheric gases, which prevents oxidation (scaling) and decarburization on the part's surface.

This results in a clean, bright finish straight from the furnace, often eliminating the need for post-treatment cleaning or machining. The vacuum also provides degassing and degreasing effects, further purifying the surface.

Enhancing Material Properties

The controlled environment allows for precise metallurgical transformations without introducing impurities. Processes in a vacuum can prevent hydrogen embrittlement, a critical failure risk for high-strength steels.

The result is improved mechanical properties, greater component lifespan, and a higher, more reliable product pass rate.

All-in-One Process Efficiency

Modern vertical vacuum furnaces are complete systems. They often integrate rapid gas quenching capabilities, allowing the entire heat treat cycle—from heating to holding to cooling—to occur in a single, sealed, and automated process.

This reduces part handling, minimizes the risk of human error, and ensures exceptional repeatability from one load to the next.

Understanding the Trade-offs and Considerations

While powerful, a vertical vacuum furnace is a specialized piece of equipment. Objectivity requires acknowledging its specific operational context and limitations.

Footprint and Facility Requirements

By their nature, vertical furnaces are tall. This demands significant overhead clearance in a facility. Bottom-loading models may even require a pit to be constructed, representing a substantial infrastructure investment.

Load Configuration Limitations

The furnace is optimized for tall, cylindrical, or easily stackable parts. It can be less efficient for processing a high mix of small, randomly shaped components compared to the broad hearth area of a horizontal furnace.

Maintenance and Accessibility

Performing maintenance inside a tall, vertical chamber can be more complex than in a horizontal furnace. Accessing heating elements or fixtures at the top or bottom of the chamber may require specialized lifts or procedures.

Making the Right Choice for Your Application

Selecting the correct furnace type depends entirely on the geometry of your parts and your primary manufacturing goal.

- If your primary focus is minimizing distortion in tall, slender, or large-ring parts: A vertical vacuum furnace is the superior technical choice for ensuring dimensional stability.

- If your primary focus is processing a high volume of varied, smaller parts: A horizontal batch furnace might offer greater loading flexibility and a more conventional facility footprint.

- If your primary focus is achieving pristine surface quality and metallurgical purity: Both furnace types are excellent, but the vertical design provides an edge for complex shapes prone to uneven gas flow or distortion.

Ultimately, choosing a vertical furnace is an investment in process control and final part quality for components where dimensional integrity is paramount.

Summary Table:

| Aspect | Key Advantage |

|---|---|

| Temperature Uniformity | Even heating in cylindrical hot zone prevents hot/cold spots |

| Distortion Mitigation | Gravity-assisted part positioning reduces warping and stress |

| Surface Quality | Vacuum prevents oxidation and decarburization for clean finishes |

| Process Efficiency | Integrated heating and quenching in one automated cycle |

| Ideal Applications | Aerospace components, long shafts, gears, and large rings |

Ready to elevate your heat treatment process with precision and reliability? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we can design a vertical vacuum furnace that perfectly matches your complex part geometries, delivering superior temperature control and minimal distortion. Don't let part warping hold you back—contact us today to discuss how KINTEK can optimize your laboratory efficiency and achieve consistent, high-quality results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance