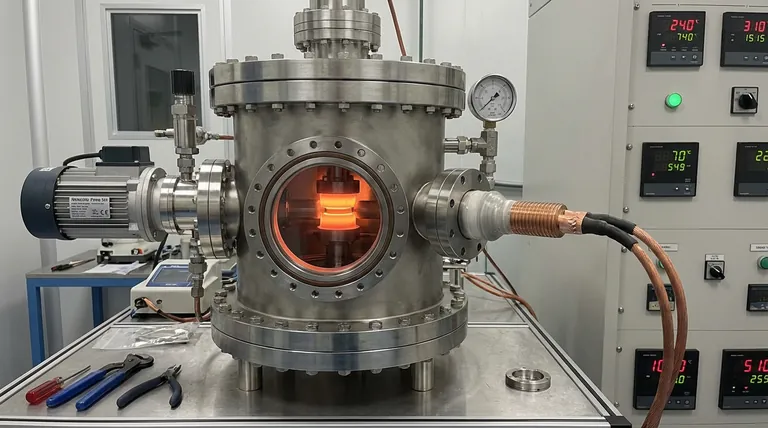

The function of the vacuum chamber is to create a high-purity environment that prevents chemical reactions during the heating phase. Specifically, it eliminates oxygen to stop the oxidation of the Inconel 718 base alloy and the BNi-2 interlayer, ensuring the materials remain chemically active for bonding.

Core Insight: The vacuum chamber is not merely a container; it is an active process variable. By maintaining an extremely low oxygen partial pressure, it guarantees the wettability of the molten interlayer, which is the absolute prerequisite for the atomic diffusion necessary to create a defect-free welded joint.

The Critical Role of Oxidation Prevention

Protecting Reactive Alloys

At the high temperatures required for Transient Liquid Phase (TLP) bonding, metal alloys become highly reactive.

The vacuum chamber protects the Inconel 718 alloy and the BNi-2 interlayer from atmospheric oxygen. Without this protection, these materials would rapidly form oxide layers that inhibit the bonding process.

Ensuring Surface Wettability

For a bond to form, the molten interlayer must spread effectively across the base metal.

Oxidation acts as a barrier, preventing this flow. The high-vacuum environment ensures the metal surfaces remain clean, facilitating excellent wettability of the molten interlayer on the base metal.

Enabling the Diffusion Mechanism

Facilitating Smooth Diffusion

TLP bonding relies on the movement of atoms (diffusion) between the interlayer and the base metal.

The vacuum environment facilitates a smooth diffusion process. By removing contaminants that would otherwise block atomic movement, the chamber allows the materials to homogenize effectively.

Achieving Defect-Free Joints

The ultimate output of this controlled environment is structural integrity.

By preventing gas entrapment and oxide inclusions, the vacuum chamber is directly responsible for producing defect-free welded joints, particularly in complex geometries like capillaries.

Operational Requirements and Trade-offs

The Necessity of High-Vacuum Equipment

Achieving this environment requires specialized hardware, typically utilizing a molecular pump set.

This equipment is essential for rapidly evacuating the chamber to the required processing level. It ensures the oxygen partial pressure is kept sufficiently low to avoid even trace contamination.

Common Pitfalls

While effective, reliance on high vacuum introduces specific constraints.

- Cycle Time: The time required to pump down the chamber can impact total processing speed.

- Leak Sensitivity: Even minor leaks in the chamber seals can raise oxygen levels enough to compromise the wettability of the BNi-2 interlayer, leading to weak joints.

Making the Right Choice for Your Project

If you are implementing electric current-assisted TLP bonding, consider the following based on your specific requirements:

- If your primary focus is Joint Integrity: Prioritize the maintenance of the molecular pump system to ensure consistent low oxygen partial pressure, as this is the core guarantee of contamination-free connections.

- If your primary focus is Process Repeatability: Monitor the vacuum levels strictly during the heating phase to ensure the wettability of the BNi-2 interlayer never fluctuates between batches.

Ultimately, the vacuum chamber determines the chemical success of the bond before the physical diffusion even begins.

Summary Table:

| Feature | Function in TLP Bonding | Impact on Joint Quality |

|---|---|---|

| Oxidation Prevention | Eliminates oxygen to protect Inconel 718 and BNi-2 | Ensures high chemical activity and surface purity |

| Wettability Control | Enables molten interlayer to spread across base metal | Prerequisite for atomic diffusion and bonding |

| Diffusion Facilitation | Removes contaminants blocking atomic movement | Allows for effective material homogenization |

| Atmospheric Control | Maintains low oxygen partial pressure | Prevents gas entrapment and oxide inclusions |

Optimize Your Advanced Bonding Processes with KINTEK

Precise atmospheric control is the foundation of successful TLP bonding and high-temperature material synthesis. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems tailored for the most demanding laboratory and industrial applications. Whether you are working with reactive Inconel alloys or complex capillary geometries, our customizable furnaces ensure the low oxygen partial pressure and thermal stability your research requires.

Ready to achieve defect-free results? Contact KINTEK today to discuss your custom furnace needs!

References

- Yueshuai Song, Min Wan. Electric Current-Assisted TLP: Bonding of Ultrathin-Walled Inconel 718 Capillaries Temperature Field Simulation and Microstructural Analysis. DOI: 10.1088/1742-6596/2679/1/012015

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What is the necessity of using a vacuum drying oven for Ni/NiO@GF precursors? Unlock Structural Precision

- What are the benefits of using graphite felt in vacuum furnaces? Achieve Superior Thermal Efficiency & Stability

- Why is it necessary to pre-bake vacuum chambers to 10^-10 mbar? Ensure High RRR in Niobium Thin Films

- How do custom vacuum furnaces ensure precise temperature control? Achieve Superior Thermal Uniformity for Your Lab

- How does resistance heating work in vacuum furnace elements? Master Precise Heat Control for Your Lab

- What are the key thermal properties of graphite for vacuum furnaces? Unlock High-Temperature Stability and Efficiency

- How is the vacuum created in a vacuum furnace? Master the Process for Superior Metallurgical Results

- What are the steps in the microwave sintering process? Unlock Faster, Superior Material Densification