Pre-baking vacuum chambers is a mandatory purification step specifically designed to desorb volatile contaminants—primarily water vapor and carbon oxides—from the internal walls of the deposition system. For niobium thin films, reaching an ultra-high vacuum (UHV) level of $10^{-10}$ mbar is critical because it prevents these residual impurities from integrating into the niobium lattice during the deposition process.

The Core Insight Niobium acts as a "getter" material, meaning it readily absorbs surrounding gases. Pre-baking ensures that the background environment is sufficiently clean to prevent oxygen and nitrogen inclusion, which is the only way to guarantee a high Residual Resistance Ratio (RRR) and optimal superconducting transition characteristics.

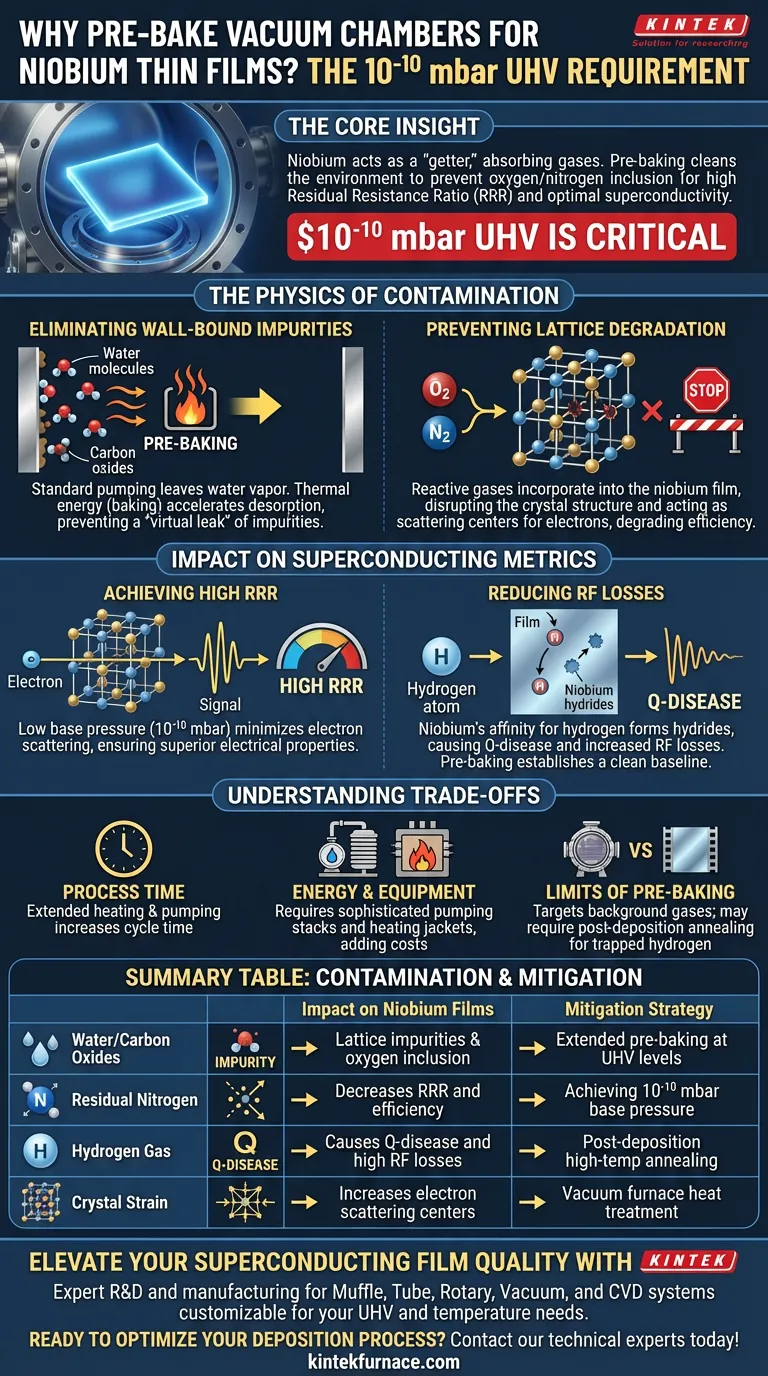

The Physics of Contamination

Eliminating Wall-Bound Impurities

Standard pumping alone is often insufficient to reach the ultra-high vacuum levels required for high-quality superconductors. Water vapor, in particular, adheres stubbornly to the internal surfaces of the vacuum chamber.

Without thermal energy (baking), this water slowly desorbs over time, acting as a "virtual leak" that creates a continuous background pressure of impurities. Extended pre-baking accelerates this desorption process, thoroughly stripping the walls of water and carbon oxides.

Preventing Lattice Degradation

During the deposition phase, the niobium atoms form a crystal lattice. If reactive gases like oxygen or nitrogen are present in the vacuum chamber, they do not merely bounce off the surface; they become chemically incorporated into the film.

This inclusion disrupts the purity of the crystal structure. Even trace amounts of these gases can act as scattering centers for electrons, effectively destroying the material's superconducting efficiency.

Impact on Superconducting Metrics

Achieving High RRR

The primary metric for the purity and quality of a superconducting material is the Residual Resistance Ratio (RRR). This is a measure of how easily electrons flow through the material at low temperatures.

A low base pressure of $10^{-10}$ mbar directly correlates to a higher RRR. By removing the source of oxygen and nitrogen via pre-baking, you minimize electron scattering, ensuring the film retains superior electrical properties.

Reducing Radio-Frequency (RF) Losses

Beyond the chemical purity of the lattice, the presence of specific impurities like hydrogen leads to distinct performance failures. Niobium has a strong affinity for hydrogen, which can form niobium hydrides upon cooling.

These hydrides are responsible for a phenomenon known as Q-disease, which drastically increases RF losses. While pre-baking helps establishes a clean baseline, it is part of a broader hygiene strategy to mitigate these microscopic defects.

Understanding the Trade-offs

Process Time vs. Film Quality

Reaching $10^{-10}$ mbar is not instant; it requires extended durations of heating and pumping. This significantly increases the cycle time for film production compared to standard high-vacuum processes.

Energy and Equipment Demands

Achieving this level of vacuum necessitates a sophisticated pumping stack, typically combining turbo molecular pumps and dry scroll pumps to move from atmosphere to UHV. Additionally, the system must be equipped with heating jackets or furnaces capable of sustaining bake-out temperatures, adding to both capital and operational costs.

The Limits of Pre-Baking

It is crucial to note that pre-baking the chamber primarily targets background gases like water and oxygen. However, it may not fully address hydrogen trapped within the niobium film after deposition.

To fully mitigate hydrogen-induced issues like the mid-field Q-slope effect, high-temperature vacuum furnaces are often employed for post-deposition annealing (e.g., at 800°C). This secondary step is required to drive out hydrogen and release micro-strains generated during the initial deposition.

Making the Right Choice for Your Goal

To optimize your niobium thin film production, align your vacuum protocol with your specific performance requirements:

- If your primary focus is maximizing RRR: Prioritize the pre-baking phase to reach $10^{-10}$ mbar, ensuring the elimination of oxygen and nitrogen that degrade lattice purity.

- If your primary focus is preventing Q-disease: Supplement your pre-baking with post-deposition annealing at high temperatures to dehydrogenate the film and relax micro-strains.

- If your primary focus is process efficiency: Evaluate if a slightly lower RRR is acceptable for your application, as this may allow for a less rigorous, time-consuming bake-out cycle.

In superconducting fabrication, extreme vacuum hygiene is not a luxury—it is the foundational requirement for functional performance.

Summary Table:

| Factor | Impact on Niobium Films | Mitigation Strategy |

|---|---|---|

| Water/Carbon Oxides | Causes lattice impurities & oxygen inclusion | Extended pre-baking at UHV levels |

| Residual Nitrogen | Decreases RRR and superconducting efficiency | Achieving $10^{-10}$ mbar base pressure |

| Hydrogen Gas | Causes Q-disease and high RF losses | Post-deposition high-temp annealing |

| Crystal Strain | Increases electron scattering centers | Vacuum furnace heat treatment |

Elevate Your Superconducting Film Quality with KINTEK

Precise vacuum hygiene is the difference between a high-performance superconductor and a failed batch. At KINTEK, we understand the rigorous demands of UHV environments. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your specific temperature and pressure requirements.

Whether you need advanced heating jackets for chamber bake-outs or specialized high-temperature vacuum furnaces for post-deposition annealing, our solutions are engineered to help you achieve maximum RRR and eliminate Q-disease.

Ready to optimize your deposition process? Contact our technical experts today to discuss your unique laboratory needs!

Visual Guide

References

- Bektur Abdisatarov, Anna Grassellino. Optimizing superconducting Nb film cavities by mitigating medium-field <i>Q</i>-slope through annealing. DOI: 10.1088/1361-6668/ade635

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Ultra High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass for KF

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Magnesium Extraction and Purification Condensing Tube Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What are the signs that a vacuum furnace hot zone needs replacement? Avoid Costly Downtime & Ensure Quality

- What is the function of a non-consumable vacuum arc furnace? Achieve Purity in FeSiBPCCuNb Alloy Synthesis

- How does a laboratory vacuum drying oven facilitate the thermal treatment of graphene/polyimide films? Enhance Purity

- What is the basic working principle of a vacuum furnace? Unlock Pure, Controlled Heat Treatment

- Why is a vacuum annealing furnace required for WSe2 Schottky detectors? Optimize Interfaces for Peak Performance

- What are the main components of a vacuum annealing furnace? Essential Systems for Precision Heat Treatment

- How does optimizing the graphite base material improve the quality of cemented carbide sintering? Master Thermal Uniformity

- Why must Graphene Oxide be dried in a vacuum at 60°C? Protect Your Nanomaterial Integrity