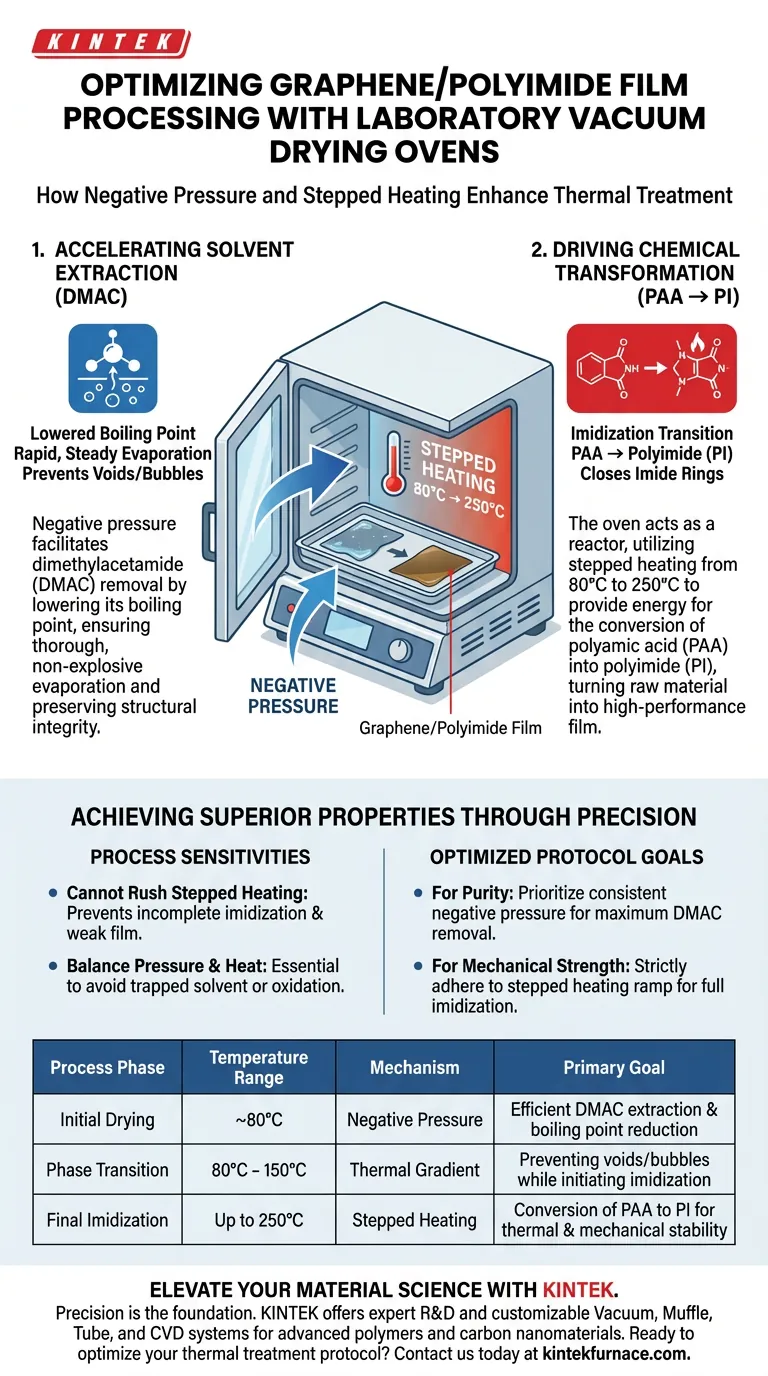

A laboratory vacuum drying oven is the critical processing tool for graphene/polyimide films because it creates a specific environment combining negative pressure with gradient-controlled temperature. This dual mechanism accelerates the removal of the solvent dimethylacetamide (DMAC) while simultaneously driving the chemical conversion of polyamic acid (PAA) into polyimide (PI). The result is a film with superior thermal stability and enhanced mechanical properties.

By integrating vacuum pressure with a stepped heating profile from 80°C to 250°C, these ovens ensure both efficient solvent extraction and complete chemical imidization, preventing defects common in standard drying methods.

The Role of Negative Pressure

Accelerating Solvent Extraction

The primary function of the vacuum environment is to facilitate the removal of dimethylacetamide (DMAC).

By creating negative pressure, the oven lowers the boiling point of the solvent.

This allows DMAC to evaporate more rapidly and thoroughly than it would under atmospheric pressure, ensuring the film is free of residual solvents that could degrade performance.

Preventing Structural Defects

Removing solvent under vacuum helps prevent the formation of voids or bubbles in the film.

A controlled negative pressure environment ensures the evaporation is steady rather than explosive.

This preserves the integrity of the graphene/polyimide composite structure during the initial drying phase.

Driving Chemical Transformation

Facilitating the Imidization Transition

Beyond simple drying, the oven acts as a reactor for a specific chemical change: the imidization of polyamic acid (PAA) into polyimide (PI).

This transition is the defining step that turns the raw precursor material into a usable, high-performance film.

The thermal field provided by the oven supplies the energy necessary to close the imide rings in the molecular chain.

Implementing Stepped Heating

The process relies on gradient-controlled temperature, specifically applying stepped heating ranging from 80°C to 250°C.

Ramping the temperature in steps is crucial for controlling the reaction rate.

It allows the material to cure uniformly, ensuring the complete transformation of the chemical structure without inducing thermal stress.

Understanding the Process Sensitivities

The Necessity of Precision

While the vacuum oven accelerates processing, the stepped heating profile cannot be rushed.

Skipping temperature steps or ramping too quickly can lead to incomplete imidization, leaving the film mechanically weak.

Balancing Pressure and Heat

Success depends on the synchronization of negative pressure and temperature.

If the vacuum is applied without the correct thermal gradient, solvent may be trapped deep within the polymer matrix as the surface skins over.

Conversely, heat without vacuum may result in oxidation or inefficient solvent removal, compromising the film's thermal stability.

Optimizing Your Thermal Treatment Protocol

To achieve consistent high-quality films, you must tailor the oven's operation to the specific chemical needs of the composite.

- If your primary focus is purity: Prioritize the maintenance of consistent negative pressure to ensure maximum removal of the DMAC solvent.

- If your primary focus is mechanical strength: Strictly adhere to the stepped heating ramp from 80°C to 250°C to guarantee full imidization of the PAA precursor.

Controlled thermal processing under vacuum is the definitive method for producing graphene/polyimide films that meet rigorous industrial standards.

Summary Table:

| Process Phase | Temperature Range | Mechanism | Primary Goal |

|---|---|---|---|

| Initial Drying | ~80°C | Negative Pressure | Efficient DMAC solvent extraction & boiling point reduction |

| Phase Transition | 80°C - 150°C | Thermal Gradient | Preventing voids/bubbles while initiating imidization |

| Final Imidization | Up to 250°C | Stepped Heating | Conversion of PAA to PI for thermal & mechanical stability |

Elevate Your Material Science with KINTEK

Precision is the foundation of high-performance graphene/polyimide composites. At KINTEK, we understand that achieving full imidization and zero-defect films requires more than just heat; it requires absolute control.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Vacuum, Muffle, Tube, and CVD systems. Whether you are processing advanced polymers or exploring new carbon nanomaterials, our lab high-temp furnaces are fully customizable to meet your specific thermal gradients and pressure requirements.

Ready to optimize your thermal treatment protocol? Contact our technical experts today to find the perfect customizable solution for your laboratory’s unique needs.

Visual Guide

References

- Zhengwu Xu, Mingxu Lu. Flexible, high temperature resistant and highly efficient E-heating graphene/polyimide film. DOI: 10.1063/5.0180858

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a vacuum drying oven play in graphene cathode manufacturing? Achieve High-Performance Battery Components

- What are the key applications of laboratory vacuum furnaces? Unlock High-Purity Material Processing

- How is temperature controlled in a vacuum heat treatment furnace? Achieve Precision and Uniformity

- What are the main applications of vacuum furnaces? Achieve Superior Material Quality and Performance

- What is the role of a constant temperature vacuum drying oven? Essential Electrode Sheet Processing Solutions

- What are the main advantages of continuous furnaces? Boost Efficiency and Cut Costs in Mass Production

- What materials are used in a vacuum furnace? Key Components for Extreme Heat & Purity

- What is the importance of the furnace shell casing in a vacuum furnace? Ensure Purity and Reliability in High-Temp Processing