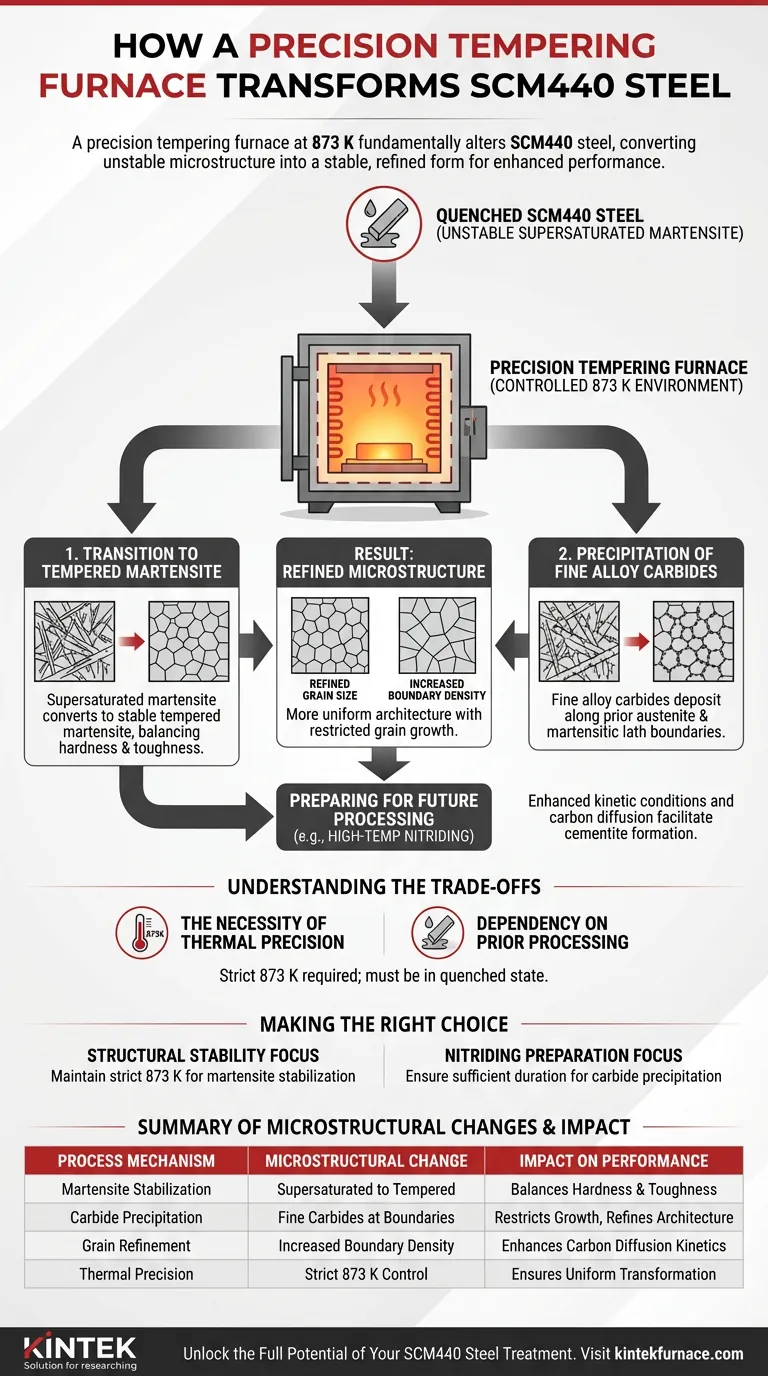

A precision tempering furnace fundamentally alters SCM440 steel by subjecting quenched specimens to a controlled thermal environment at 873 K. This specific temperature regime drives the phase transformation of unstable supersaturated martensite into stable tempered martensite while simultaneously triggering the precipitation of fine alloy carbides along specific microstructural boundaries.

Precision tempering is not merely a stress-relief step; it is a critical pre-treatment that refines grain architecture and establishes the kinetic conditions necessary for effective high-temperature nitriding.

Mechanisms of Microstructural Transformation

Transitioning to Tempered Martensite

The primary function of the furnace at 873 K is to stabilize the steel's matrix. The process facilitates the transformation of supersaturated martensite, which is inherently unstable following quenching, into tempered martensite. This conversion is essential for balancing the hardness and toughness of the material.

Precipitation of Fine Alloy Carbides

During this thermal soak, fine alloy carbides begin to precipitate out of the matrix. These carbides do not form randomly; they deposit specifically along the prior austenite grain boundaries and the martensitic lath boundaries. This targeted precipitation is a hallmark of precision pre-treatment.

The Impact on Grain Architecture

Refinement of Grain Size

The formation of tempered martensite and the strategic placement of carbides result in a significant refinement of the grain size. By restricting grain growth, the furnace ensures a more uniform and robust microstructure.

Increasing Boundary Density

As the grain size decreases, the total interfacial area within the steel increases. This leads to a higher grain boundary density, which physically alters how elements can move through the material structure.

Preparing for Future Processing

Enhancing Carbon Diffusion Kinetics

The microstructural changes induced by the furnace are not an end in themselves but a preparation for subsequent steps. The refined structure provides the necessary kinetic conditions to support chemical changes in later stages.

Facilitating Cementite Formation

Specifically, this pre-treatment prepares the steel for high-temperature nitriding. The increased grain boundary density and stable matrix aid in carbon diffusion and the eventual formation of cementite during the nitriding process.

Understanding the Trade-offs

The Necessity of Thermal Precision

The benefits of this process rely entirely on maintaining the specific temperature of 873 K. Deviations from this precise thermal point can fail to trigger the correct precipitation of carbides.

Dependency on Prior Processing

This tempering process assumes the steel is already in a quenched state. Attempting this treatment on non-quenched SCM440 would not yield the transition from supersaturated to tempered martensite, rendering the pre-treatment ineffective for its intended kinetic purpose.

Making the Right Choice for Your Goal

To maximize the utility of SCM440 steel, align your furnace parameters with your specific processing objectives.

- If your primary focus is structural stability: Ensure the furnace maintains a strict 873 K profile to fully resolve supersaturated martensite into tempered martensite.

- If your primary focus is preparing for nitriding: Verify that the heat treatment duration allows for sufficient precipitation of fine alloy carbides to maximize grain boundary density.

By controlling the tempering phase with precision, you effectively program the steel's microstructure for optimal performance in subsequent surface hardening treatments.

Summary Table:

| Process Mechanism | Microstructural Change | Impact on Material Performance |

|---|---|---|

| Martensite Stabilization | Supersaturated to Tempered Martensite | Balances hardness and toughness |

| Carbide Precipitation | Fine alloy carbides at boundaries | Restricts grain growth and refines architecture |

| Grain Refinement | Increased grain boundary density | Enhances carbon diffusion kinetics |

| Thermal Precision | Strict 873 K temperature control | Ensures uniform phase transformation |

Unlock the Full Potential of Your SCM440 Steel Treatment

Precision matters when your material's performance depends on exact microstructural transformations. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnaces designed to maintain the strict thermal profiles required for high-end metallurgy.

Our expert R&D and customizable manufacturing solutions ensure that your lab achieves the precise 873 K environment necessary for carbide precipitation and grain refinement. Don't leave your pre-treatment results to chance—partner with KINTEK for reliable, high-temp lab systems tailored to your unique SCM440 processing needs.

Ready to elevate your heat treatment precision? Contact us today to find your custom furnace solution!

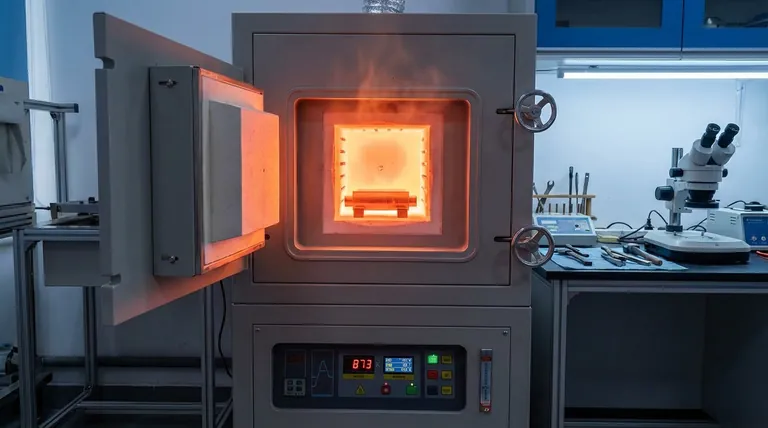

Visual Guide

References

- M.H. Kim, Osamu Umezawa. Influence of Prior Quenching and Tempering Treatment on Cementite Formation during Nitriding at 913 K for SCM440 Steel. DOI: 10.2355/isijinternational.isijint-2024-367

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is an argon atmosphere used? Ensure Material Purity in High-Temp Processes

- How does a controlled atmosphere furnace ensure precision and reliability? Unlock Consistent Material Processing

- What is the significance of the flow distribution coefficient (fdi)? Optimize Heat Transfer in Annealing Furnaces

- What role does a high-temperature inert atmosphere furnace play in carbonization? Optimize Your Carbon Yield

- What role does a high-temperature furnace play in uranyl silicate crystal growth? Master Precision Thermal Control

- What is a box type annealing atmosphere furnace? Master Controlled Heat Treatment for Superior Materials

- What is the function of an air annealing furnace? Enhance Ho:Y2O3 Ceramics Transparency and Performance

- Why is a high-temperature reaction furnace with CO2 control necessary for activated carbon? Unlock Maximum Porosity