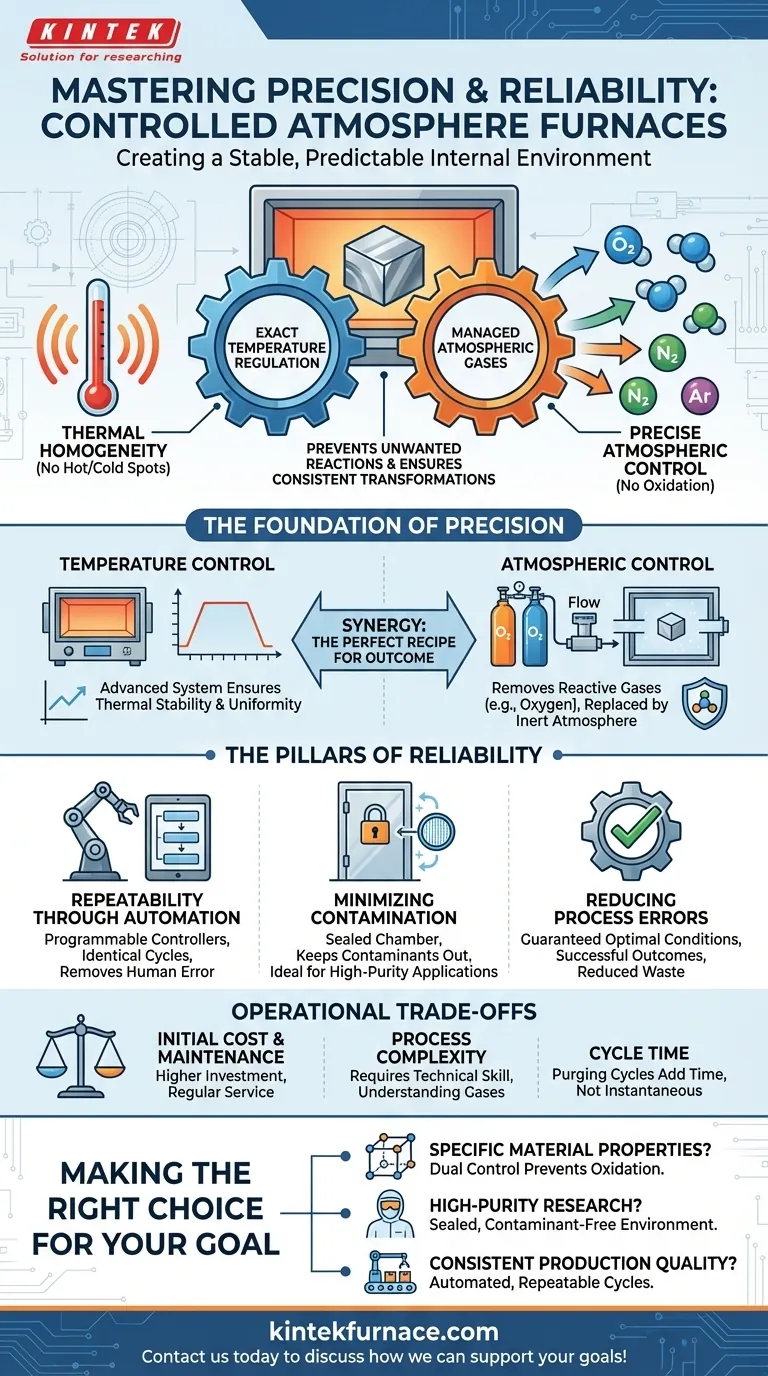

In essence, a controlled atmosphere furnace ensures precision and reliability by creating a highly stable and predictable internal environment. It achieves this through two core functions: exacting temperature regulation and the deliberate management of the atmospheric gases surrounding the workpiece, which together prevent unwanted chemical reactions and ensure consistent material transformations.

For any process where material properties are paramount, uncontrolled variables are the primary source of failure. A controlled atmosphere furnace systematically eliminates the two most critical variables—atmospheric reactivity and thermal fluctuation—thereby turning a sensitive process into a scientifically repeatable one.

The Foundation of Precision: Mastering the Environment

True precision in material processing comes from absolute control over the conditions of transformation. A controlled atmosphere furnace is designed specifically to establish and maintain this control.

Exact Temperature Control

An advanced temperature control system is the furnace's central nervous system. It does more than just reach a setpoint; it ensures thermal homogeneity, meaning the temperature is uniform throughout the entire heating chamber.

This prevents hot or cold spots on the material, which could otherwise lead to inconsistent results, internal stresses, or failed treatments. The system constantly monitors and adjusts to maintain this stability with minimal deviation.

Precise Atmospheric Control

This is what distinguishes a controlled atmosphere furnace from a standard one. The goal is to remove reactive gases, primarily oxygen, and replace them with a specific, controlled atmosphere.

By purging the chamber and introducing a specific gas—often inert gases like nitrogen or argon—the furnace prevents oxidation and other unwanted chemical reactions that can ruin a material's surface finish, purity, or structural integrity at high temperatures.

The Synergy of Temperature and Atmosphere

Neither control is sufficient on its own. A perfect temperature profile is useless if the material oxidizes and becomes brittle. Likewise, a perfectly inert atmosphere cannot achieve the desired metallurgical phase change without the correct thermal cycle.

Precision is achieved when these two systems work in concert, creating a "recipe" of temperature and atmosphere that dictates the exact physical and chemical outcome for the material.

The Pillars of Reliability: From Design to Operation

Reliability is not just about a single successful run; it's about achieving the exact same successful outcome every single time. This is built into the furnace's design and operational principles.

Repeatability Through Automation

Modern furnaces use programmable controllers to automate the entire process. Once a successful recipe of temperature ramps, holds, and gas flow rates is established, it can be saved and executed identically for every subsequent batch.

This automation removes the risk of human error from cycle to cycle, which is the cornerstone of producing a stable, reliable product.

Minimizing Contamination

The sealed nature of the furnace chamber serves a dual purpose. It not only keeps the controlled atmosphere in but also keeps external contaminants out.

This is critical for high-purity applications, such as in the electronics or medical device industries, where even trace amounts of foreign particles can cause a component to fail.

Reducing Process Errors

By controlling the key variables, the furnace dramatically minimizes the chance of project failure. Processes like brazing, sintering, or annealing are guaranteed to occur under optimal conditions, leading to successful outcomes and reducing costly rework or material waste.

Understanding the Operational Trade-offs

While powerful, these furnaces are not without their complexities. Acknowledging the trade-offs is key to successful implementation.

Initial Cost and Maintenance

The precision comes at a price. The initial investment for a controlled atmosphere furnace is higher than for a standard air furnace due to the need for a sealed chamber, gas delivery systems, and more sophisticated controls. Regular maintenance of seals, sensors, and gas purifiers is also required.

Process Complexity

Operating the furnace requires a greater degree of technical skill. Users must understand the properties of different gases, safety protocols (especially for flammable gases like hydrogen), and the principles of creating and maintaining a specific atmosphere. It is not a simple "plug-and-play" device.

Cycle Time

Achieving a pure atmosphere is not instantaneous. The process involves purging cycles to remove ambient air, which adds time to the overall process. This can be a consideration for high-throughput production environments.

Making the Right Choice for Your Goal

To determine if this technology fits your needs, align its core strengths with your primary objective.

- If your primary focus is achieving specific material properties: The dual control of temperature and atmosphere is the most critical feature, as it prevents oxidation and ensures the desired metallurgical structure.

- If your primary focus is high-purity research or sensitive component manufacturing: The furnace's ability to create a sealed, inert, and contaminant-free environment is its key advantage.

- If your primary focus is consistent production quality: The automated control systems that enable perfectly repeatable process cycles are what will guarantee reliability and minimize defects.

Ultimately, mastering the furnace's environment empowers you to master your material's final outcome.

Summary Table:

| Key Aspect | Function | Benefit |

|---|---|---|

| Temperature Control | Ensures uniform heating and stability | Prevents material defects and inconsistencies |

| Atmospheric Control | Manages gases to prevent oxidation | Maintains material purity and integrity |

| Automation | Uses programmable controllers for repeatable cycles | Reduces human error and ensures batch consistency |

| Sealed Chamber | Keeps contaminants out and atmosphere in | Ideal for high-purity applications in electronics and medical devices |

Ready to elevate your material processing with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in research, electronics, or production, our controlled atmosphere furnaces ensure consistent, high-quality outcomes. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality