Precise thermal regulation is the cornerstone of processing quasicrystal-reinforced aluminum matrix composites. A laboratory high-temperature furnace ensures structural integrity by maintaining an exacting temperature, typically around 530 °C, to fully dissolve strengthening elements into the aluminum matrix without inducing localized melting or surface degradation.

Core Insight The furnace’s primary function is not just heating, but achieving thermal uniformity to create a supersaturated solid solution. This precise control prevents "over-burning" of low-melting phases and sets the microstructural stage for precipitation hardening, which is the actual source of the composite's final strength.

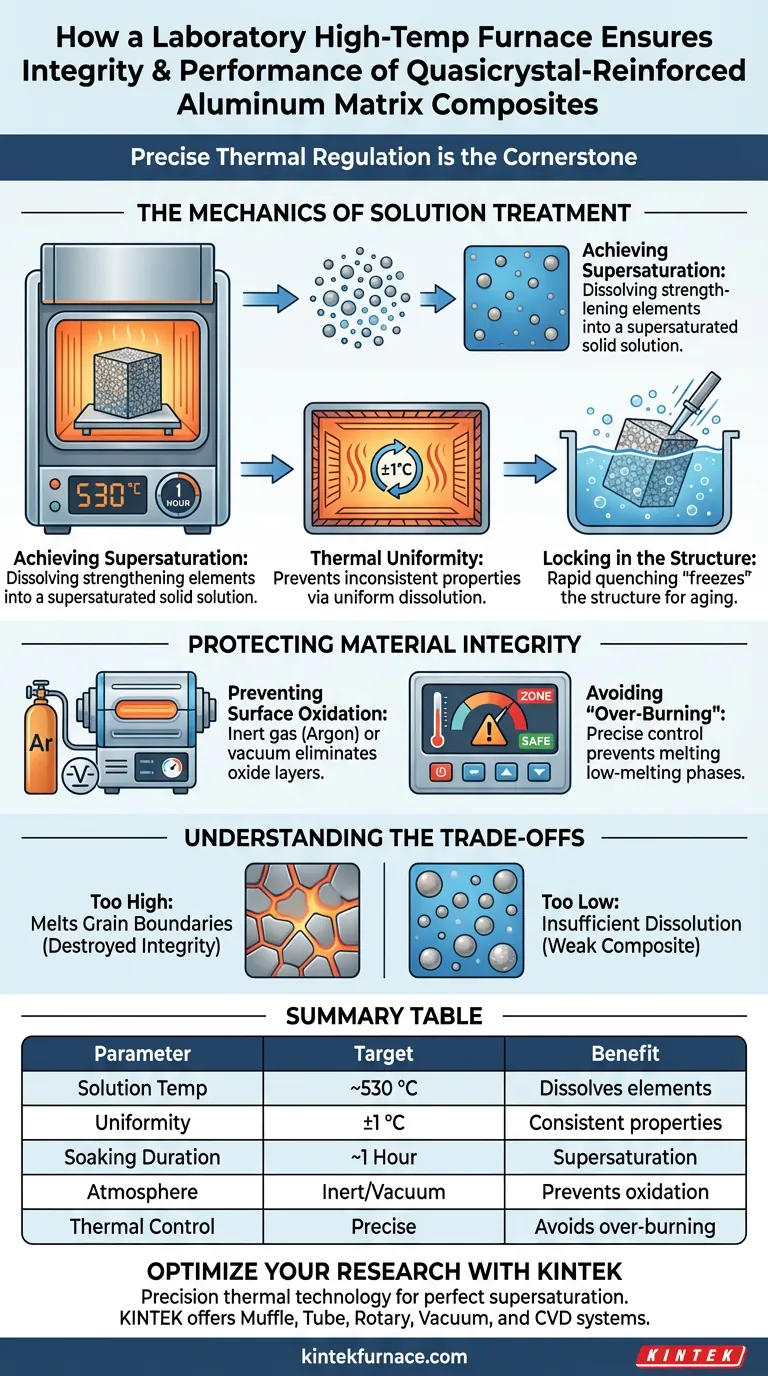

The Mechanics of Solution Treatment

Achieving Supersaturation

The fundamental goal of using a high-temperature furnace for these composites is to dissolve strengthening elements into the aluminum matrix.

By holding the material at a specific temperature (e.g., 530 °C) for a set duration (e.g., one hour), the furnace forces these elements to integrate into a single-phase solid solution.

This state is termed a supersaturated solid solution, which is chemically unstable but physically necessary for future strengthening.

The Role of Thermal Uniformity

Uniformity within the furnace chamber is more critical than the maximum temperature capability.

The furnace must ensure that the temperature does not fluctuate across the sample’s geometry.

If the temperature varies, the dissolution of elements will be uneven, leading to inconsistent mechanical properties across the composite.

Locking in the Structure

Once the solid solution is formed, the furnace's job involves preparing the material for rapid water quenching.

This sudden cooling "freezes" the supersaturated structure in place.

This step is the prerequisite for the subsequent aging process, where dispersed strengthening phases (such as beta double prime, beta prime, and Al2CuMg) precipitate to reinforce the material.

Protecting Material Integrity

Preventing Surface Oxidation

At high solution temperatures, aluminum composites are highly reactive to oxygen.

Advanced furnaces, particularly tube vacuum types, mitigate this by evacuating air and backfilling with inert gas (like argon).

This creates an oxygen-free environment that preserves the surface finish and prevents the formation of brittle oxide layers that could initiate cracks.

Avoiding "Over-Burning"

Aluminum composites often contain eutectic phases with melting points lower than the primary matrix.

If the furnace temperature overshoots even slightly, these phases can melt, a defect known as localized over-burning.

Precise control prevents this incipient melting, ensuring the structural framework remains solid while the alloying elements dissolve.

Understanding the Trade-offs

The Risk of Thermal Overshoot

Pushing the temperature too high to accelerate dissolution is a common error.

While it ensures all elements dissolve, it risks melting grain boundaries (eutectic phases), which permanently destroys the material's structural integrity.

The Cost of Insufficient Heating

Conversely, being too conservative with temperature settings leads to insufficient solid solution.

If the temperature is too low, the strengthening elements remain undissolved.

This means that during the subsequent aging phase, there will be no precipitates to strengthen the material, rendering the composite significantly weaker than designed.

Making the Right Choice for Your Goal

To maximize the performance of quasicrystal-reinforced aluminum matrix composites, align your furnace capabilities with your specific processing needs.

- If your primary focus is Maximum Mechanical Strength: Prioritize a furnace with exceptional thermal uniformity (±1°C) to safely approach the solution limit without over-burning.

- If your primary focus is Surface Integrity: Select a vacuum or atmosphere-controlled furnace to eliminate oxidation during the high-temperature soak.

Success lies in the balance between dissolving strengthening elements and preserving the matrix structure through rigorous temperature control.

Summary Table:

| Process Parameter | Target Value/Requirement | Benefit to Composite |

|---|---|---|

| Solution Temperature | ~530 °C | Dissolves strengthening elements into matrix |

| Thermal Uniformity | ±1 °C | Ensures consistent mechanical properties |

| Soaking Duration | ~1 Hour | Achieves supersaturated solid solution |

| Atmosphere | Inert (Argon) or Vacuum | Prevents surface oxidation and brittleness |

| Thermal Control | Precise Regulation | Avoids localized melting (over-burning) |

Optimize Your Composite Research with KINTEK

Precision is the difference between a high-performance composite and a failed experiment. KINTEK provides the cutting-edge thermal technology required to achieve perfect supersaturation while protecting your material’s structural integrity.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all specifically designed for the rigorous demands of laboratory metallurgy. Whether you need exceptional thermal uniformity or controlled atmosphere processing, our lab high-temp furnaces are fully customizable to meet your unique material needs.

Ready to elevate your material science outcomes? Contact us today to find your custom furnace solution!

Visual Guide

References

- Juan Wang, Zhong Yang. Microstructure and Properties of Al-Cu-Fe-Ce Quasicrystalline-Reinforced 6061 Aluminum Matrix Composites after Aging. DOI: 10.3390/coatings14030372

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a vacuum oven required during the preparation of Al-CNTs/h-BN composites? Prevent Defects & Ensure Purity

- Why is thermal growth oxidation preferred for SiO2 gate dielectrics? Superior Quality for a-IGZO TFTs

- What are the core technical advantages of an industrial microwave sintering system? Gain Speed and Material Integrity

- Why is graphite furnace AAS more sensitive than flame AAS? Unlocking Trace-Level Detection

- Why is dual heat treatment required for SnO2 nanoparticles? Optimize Oxidation for Superior Performance

- What role do high-temperature sintering furnaces play in ceramic SLA? Unlock 99% Density in 3D Printed Ceramics

- How do thermal stripping tools and heating equipment facilitate solar panel recycling? High-Value Glass Recovery Guide

- What are some common types of batch furnaces? Find Your Perfect Heat Treatment Solution