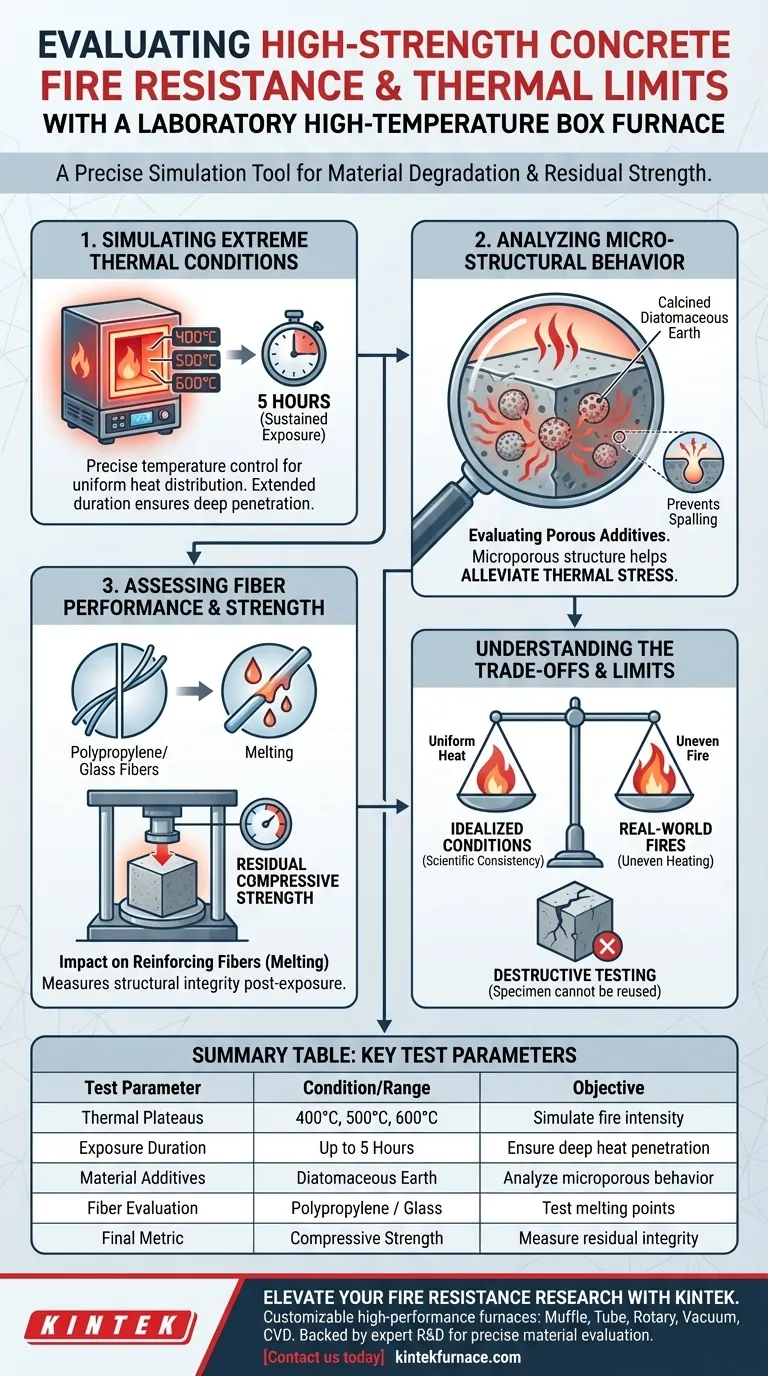

A laboratory high-temperature box furnace serves as a precise simulation tool for evaluating how high-strength concrete withstands extreme heat. By exposing specimens to specific thermal plateaus of 400°C, 500°C, and 600°C for durations of up to five hours, researchers can isolate and measure the material's degradation and residual strength.

By maintaining a controlled environment, this equipment allows for the critical analysis of internal micro-structures and fiber behavior, quantifying exactly how additives alleviate thermal stress before structural failure occurs.

Simulating Extreme Thermal Conditions

Precise Temperature Control

The box furnace allows researchers to target specific high-temperature levels crucial for fire safety testing.

According to standard protocols, the equipment creates a stable environment at 400°C, 500°C, and 600°C.

Sustained Heat Exposure

Reaching high temperatures is not enough; the duration of exposure determines the depth of heat penetration.

The furnace maintains these target temperatures for 5 hours.

This extended duration ensures that the thermal stress affects the entire concrete specimen, not just the outer surface layer.

Analyzing Micro-Structural Behavior

Evaluating Porous Additives

The furnace is instrumental in testing the efficacy of additives like Calcined Diatomaceous Earth.

Researchers use the data from these tests to examine the additive's microporous structure.

Alleviating Thermal Stress

The primary goal of this analysis is to understand how the microporous structure functions under heat.

Specifically, the test reveals how these pores help alleviate thermal stress within the concrete matrix, potentially preventing explosive spalling or cracking.

Assessing Fiber Performance and Strength

Impact on Reinforcing Fibers

High-strength concrete often contains fibers that react differently to heat than the cement paste.

The furnace creates conditions that melt materials like polypropylene or glass fibers.

Measuring Residual Compressive Strength

Once the fibers have melted or degraded, the core structural question remains.

The test allows engineers to measure the residual compressive strength of the concrete.

This data point confirms whether the concrete retains structural integrity after the internal reinforcement has been compromised by heat.

Understanding the Trade-offs

Idealized vs. Real-World Conditions

A box furnace provides a uniform heat distribution, which is necessary for scientific consistency.

However, this differs from real-world fires, which often subject structures to uneven heating and rapid thermal gradients.

The Limits of Destructive Testing

The process described is inherently destructive.

Once the concrete is exposed to these temperatures for 5 hours to measure residual strength, the specimen cannot be re-tested or used for other analyses.

Making the Right Choice for Your Goal

To utilize a high-temperature box furnace effectively for concrete evaluation, consider your specific testing objectives:

- If your primary focus is material formulation: Use the furnace to determine if the microporous structure of Calcined Diatomaceous Earth is effectively reducing thermal stress at the 500-600°C range.

- If your primary focus is structural safety: Concentrate on the residual compressive strength data to understand how the melting of polypropylene or glass fibers affects the load-bearing capacity after a 5-hour exposure.

Reliable fire resistance data depends on rigorous, sustained thermal simulation to reveal the true limits of your material.

Summary Table:

| Test Parameter | Condition/Range | Objective |

|---|---|---|

| Thermal Plateaus | 400°C, 500°C, 600°C | Simulate specific fire intensity levels |

| Exposure Duration | Up to 5 Hours | Ensure deep heat penetration into the specimen |

| Material Additives | Diatomaceous Earth | Analyze microporous behavior under thermal stress |

| Fiber Evaluation | Polypropylene / Glass | Test melting points and impact on reinforcement |

| Final Metric | Compressive Strength | Measure residual structural integrity post-exposure |

Elevate Your Fire Resistance Research with KINTEK

Precise material evaluation requires high-performance heating solutions that you can trust. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique testing protocols.

Whether you are analyzing micro-structural behavior or measuring residual compressive strength, our furnaces provide the stability and control your lab needs. Contact us today to discover how KINTEK’s advanced thermal technology can empower your next breakthrough in high-strength concrete and material science.

Visual Guide

References

- Muttaqin Hasan, Taufiq Saidi. Properties of High-Strength Concrete Incorporating Calcined Diatomaceous Earth, Polypropylene, and Glass Fibers. DOI: 10.3390/buildings15020225

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What types of workpieces are suitable for box type high-temperature resistance furnaces? Versatile Solutions for Metals, Ceramics, and More

- What are the common applications of benchtop furnaces? Unlock Precision in Materials Science and More

- What are the advantages of using a vacuum muffle furnace in a lab? Boost Efficiency and Purity in Material Processing

- How does a high-temperature box resistance furnace synthesize WC/C@N-S nanocatalysts? Precision Thermal Control

- How are box furnaces used in industrial applications? Versatile Batch Processing for Heat Treating and More

- What are the advantages of using a muffle furnace? Achieve Precise, Contamination-Free Heat Treatment

- What is the process logic of a muffle furnace for tungsten oxynitride thin films? Optimize Your Thermal Cycle

- What role does an industrial muffle furnace play in the calcination of Y211? Master Single-Phase Synthesis