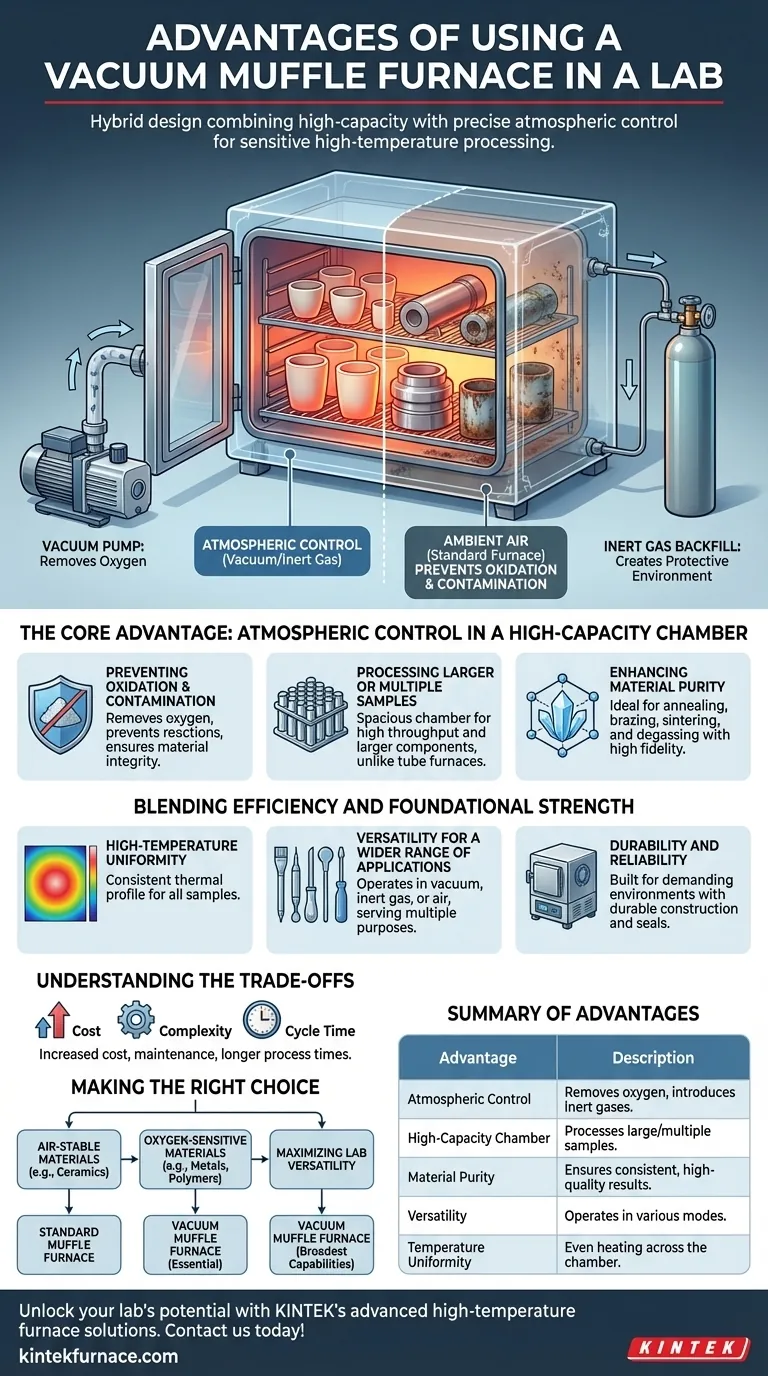

In a modern laboratory, a vacuum muffle furnace represents a significant upgrade in processing capability by combining the high-capacity chamber of a traditional muffle furnace with the precise atmospheric control of a tube furnace. This unique hybrid design allows for the high-temperature treatment of sensitive materials, preventing oxidation and contamination while enabling higher throughput than more restrictive furnace types.

The core value of a vacuum muffle furnace is its ability to protect materials from air at high temperatures. By first removing oxygen with a vacuum and then introducing an inert gas, it provides a large, stable, and controlled environment for processes where purity and material integrity are paramount.

The Core Advantage: Atmospheric Control in a High-Capacity Chamber

The defining feature of a vacuum muffle furnace is its ability to manipulate the atmosphere within its spacious chamber. This unlocks capabilities that are impossible with a standard furnace that operates in ambient air.

Preventing Oxidation and Contamination

Many advanced materials, metals, and ceramics react with oxygen at high temperatures. This oxidation can ruin samples, alter their chemical properties, and compromise research results.

A vacuum muffle furnace solves this by first using a vacuum pump to remove the air (and thus, the oxygen) from the chamber. The chamber can then be backfilled with an inert gas, such as argon or nitrogen, creating a protective, non-reactive environment for the heating process.

Processing Larger or Multiple Samples

While tube furnaces also offer atmospheric control, their small-diameter tube limits the size and quantity of samples you can process at one time.

A vacuum muffle furnace provides a much larger, box-shaped chamber. This allows you to process large individual components or run batches of many smaller samples simultaneously, dramatically improving laboratory efficiency and throughput.

Enhancing Material Purity and Properties

For applications in materials science, metallurgy, and electronics, the final properties of a component are directly tied to the purity of its processing environment.

By eliminating reactive gases, a vacuum muffle furnace ensures that processes like annealing, brazing, sintering, and degassing are performed with maximum fidelity. This leads to more consistent, reliable, and higher-quality end products.

Blending Efficiency and Foundational Strength

A vacuum muffle furnace is not just about atmospheric control; it's about integrating that capability into a robust and efficient platform. It builds upon the established benefits of a standard muffle furnace.

High-Temperature Uniformity

Like their conventional counterparts, vacuum muffle furnaces are designed with heating elements distributed around the chamber to provide excellent temperature uniformity. This ensures that all samples, regardless of their position, experience the same thermal profile.

Versatility for a Wider Range of Applications

Because it can be operated with a vacuum, with an inert gas atmosphere, or simply in air like a standard furnace, this single piece of equipment can serve multiple purposes. This versatility can save significant lab space and capital expense compared to purchasing separate furnaces for different tasks.

Durability and Reliability

These furnaces are built for demanding industrial and research environments. They typically feature durable construction, high-quality insulation for thermal efficiency, and robust sealing systems to maintain the integrity of the vacuum or inert atmosphere.

Understanding the Trade-offs

While powerful, a vacuum muffle furnace is not the default choice for every application. Understanding its limitations is key to making a sound investment.

Increased Cost and Complexity

The addition of a vacuum pump, gas plumbing, seals, and control systems makes a vacuum muffle furnace more expensive and complex than a standard muffle furnace. The system requires proper maintenance of vacuum seals and pumps to function correctly.

Vacuum Level Limitations

These furnaces are designed to create a low or medium vacuum environment sufficient for purging oxygen. They are not ultra-high vacuum (UHV) systems. For applications requiring extremely low pressures, a dedicated UHV chamber is necessary.

Longer Process Cycle Times

The steps of pumping the chamber down to a vacuum and then backfilling it with inert gas add time to each process cycle. If your application does not require atmospheric control, a standard muffle furnace will offer faster cycle times.

Making the Right Choice for Your Application

Selecting the correct furnace requires a clear understanding of your material, process, and throughput goals.

- If your primary focus is high-temperature processing of air-stable materials (e.g., ceramics): A standard muffle furnace is the most cost-effective and straightforward solution.

- If your primary focus is processing oxygen-sensitive materials (e.g., metal alloys, certain polymers): A vacuum muffle furnace is essential to prevent oxidation and ensure material integrity.

- If your primary focus is maximizing lab versatility with a single instrument: The vacuum muffle furnace offers the broadest range of capabilities, serving as both an air and inert-atmosphere furnace.

- If your primary focus is small, highly-controlled samples or chemical vapor deposition (CVD): A dedicated tube furnace might provide more specialized control for your specific geometry.

By aligning the furnace's capabilities with your specific scientific needs, you ensure your investment directly supports your research and production goals.

Summary Table:

| Advantage | Description |

|---|---|

| Atmospheric Control | Removes oxygen and introduces inert gases to prevent oxidation and contamination. |

| High-Capacity Chamber | Allows processing of large or multiple samples, improving throughput. |

| Material Purity | Ensures consistent results in annealing, sintering, and other processes. |

| Versatility | Operates in vacuum, inert gas, or air modes for diverse applications. |

| Temperature Uniformity | Provides even heating across the chamber for reliable thermal profiles. |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Whether you're processing sensitive materials or aiming for higher throughput, our vacuum muffle furnaces deliver precise atmospheric control and efficiency. Contact us today to discuss how we can enhance your research and production processes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing