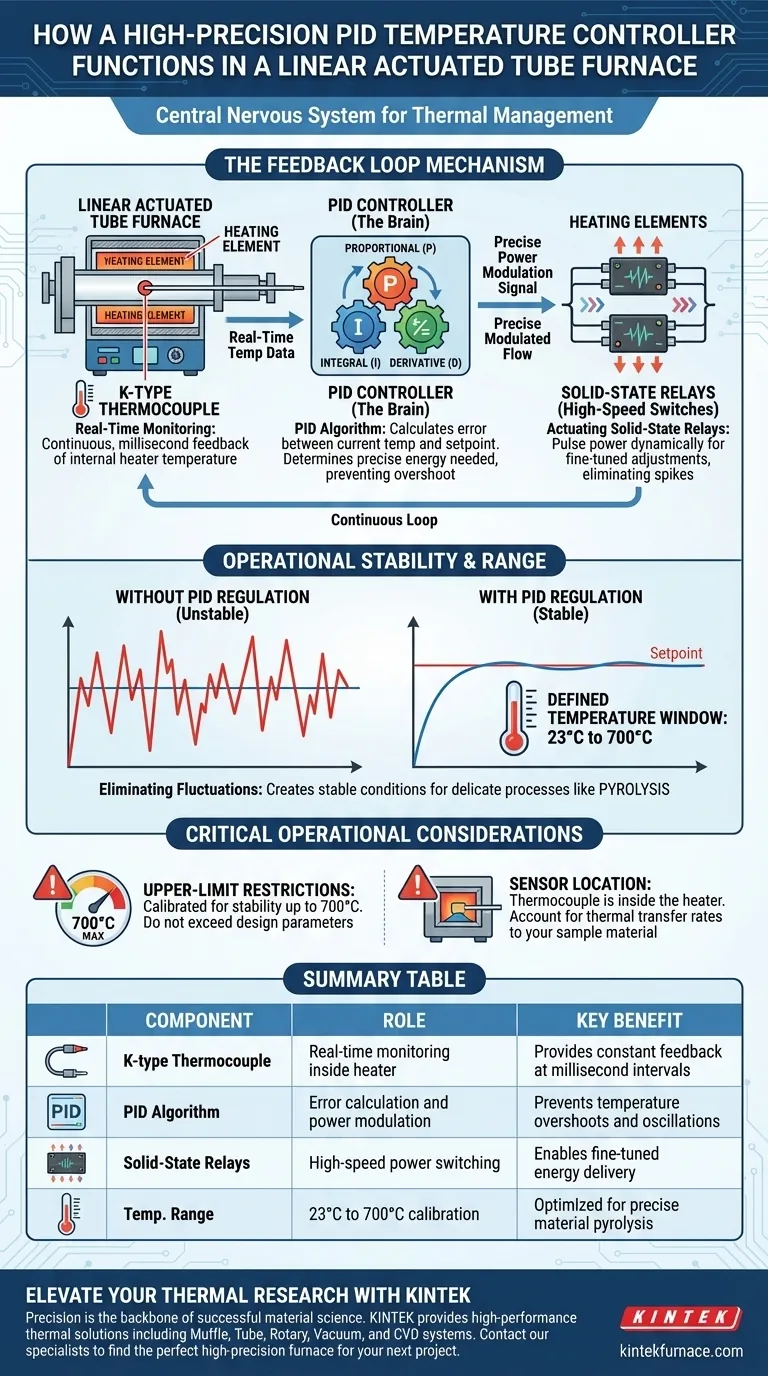

A high-precision PID temperature controller functions as the central nervous system of the furnace's thermal management. It continuously monitors real-time heat data from a K-type thermocouple positioned within the heater. By processing this feedback through a Proportional-Integral-Derivative (PID) algorithm, it dynamically regulates solid-state relays to modulate power flow, ensuring the temperature remains locked to your specific setpoint.

The PID controller transforms a standard heating element into a precision tool. By eliminating natural thermal fluctuations, it creates the stable thermodynamic conditions necessary for delicate processes like pyrolysis within a 23°C to 700°C range.

The Feedback Loop Mechanism

Real-Time Monitoring

The foundation of the system is the K-type thermocouple located directly inside the heater.

This sensor provides continuous, real-time feedback to the controller, reporting the exact internal temperature at any given millisecond.

The PID Algorithm

The controller does not simply turn the heat "on" or "off." It employs a proportional-integral-derivative algorithm.

This algorithm calculates the error between the current temperature and your target setpoint. It then determines the precise amount of energy required to close that gap without overshooting.

Actuating Solid-State Relays

To execute its calculations, the controller manages solid-state relays.

These relays act as high-speed switches. They pulse power to the heating elements dynamically, allowing for fine-tuned adjustments rather than crude temperature spikes.

Operational Stability and Range

Eliminating Fluctuations

The primary function of this rapid sensing and switching loop is to eliminate temperature fluctuations.

Without this dynamic regulation, the thermal environment would oscillate, potentially ruining sensitive materials.

Defined Temperature Window

This specific control system is engineered to maintain stable setpoints between 23°C and 700°C.

This range is specifically optimized to provide the precise thermodynamic conditions required for the pyrolysis of materials in specific combustion modes.

Critical Operational Considerations

Upper-Limit Restrictions

It is vital to note the hard ceiling of the system's capabilities.

The controller is calibrated for stability up to 700°C. Attempting to drive the system beyond this limit exceeds the specified design parameters for precise control.

Sensor Location

The reference indicates the thermocouple is located inside the heater, not necessarily inside the sample itself.

Users must be aware that while the heater temperature is perfectly regulated, they should account for thermal transfer rates to their specific material sample.

Making the Right Choice for Your Goal

To maximize the utility of this linear actuated tube furnace system, align your experimental goals with the controller’s specific capabilities:

- If your primary focus is material pyrolysis: Rely on the PID algorithm to eliminate fluctuations, ensuring the specific combustion modes are not compromised by thermal instability.

- If your primary focus is broad-range thermal cycling: Verify that your required protocols strictly adhere to the 23°C to 700°C operational window to maintain high-precision control.

By leveraging the controller's dynamic regulation, you ensure that your experimental results are a product of your chemistry, not thermal error.

Summary Table:

| Component | Role within System | Key Benefit |

|---|---|---|

| K-type Thermocouple | Real-time monitoring inside heater | Provides constant feedback at millisecond intervals |

| PID Algorithm | Error calculation and power modulation | Prevents temperature overshoots and oscillations |

| Solid-State Relays | High-speed power switching | Enables fine-tuned energy delivery to heating elements |

| Temp. Range | 23°C to 700°C calibration | Optimized for precise material pyrolysis and stability |

Elevate Your Thermal Research with KINTEK

Precision is the backbone of successful material science. KINTEK provides high-performance thermal solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your specific laboratory requirements. Backed by expert R&D and world-class manufacturing, we ensure your experiments benefit from the most stable thermodynamic conditions possible.

Don't let thermal fluctuations compromise your results. Contact our specialists today to find the perfect high-precision furnace for your next project.

Visual Guide

References

- Casey Coffland, Elliott T. Gall. An open-source linear actuated-quartz tube furnace with programmable ceramic heater movement for laboratory-scale studies of combustion and emission. DOI: 10.2139/ssrn.5687995

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the role of the tubular furnace annealing process in the synthesis of Si@SnO2? Achieve Precise Nanocoatings

- How does a vacuum tube furnace support the sintering process of np-CuSn films? Achieve High-Purity Intermetallic Joints

- Why is vacuum control critical when using a horizontal tube furnace for the 550 °C annealing of a-SiC:H films?

- What are the common uses of vertical fluidized bed tube furnaces in laboratory research? Discover Precision Thermal Solutions

- What critical process conditions does a tube atmosphere furnace provide for Sr2CuWO6? Control Atmosphere & Temperature

- What is the primary role of a tube furnace in CuGaO2 treatment? Enhance Crystallization and Film Performance

- What is the primary function of a high-temperature tube furnace in solid-state chemical synthesis? | Expert Guide

- Why is a tube reduction furnace used for the pre-reduction of CeAlOx/NiO/Ni-foam catalysts? Essential Catalyst Prep