A high-precision box muffle furnace secures the final performance of alumina ceramics by strictly controlling the thermal environment to manage grain structure development. Through superior temperature control precision and thermal field uniformity, these furnaces regulate grain boundary migration rates, ensuring the material achieves full densification while inhibiting abnormal grain growth.

The core value of high precision lies in its ability to decouple densification from grain coarsening. By executing accurate programmed heating curves, the furnace ensures that solid-phase reactions and grain growth occur synchronously across the entire workpiece, resulting in superior mechanical strength and a defect-free microstructure.

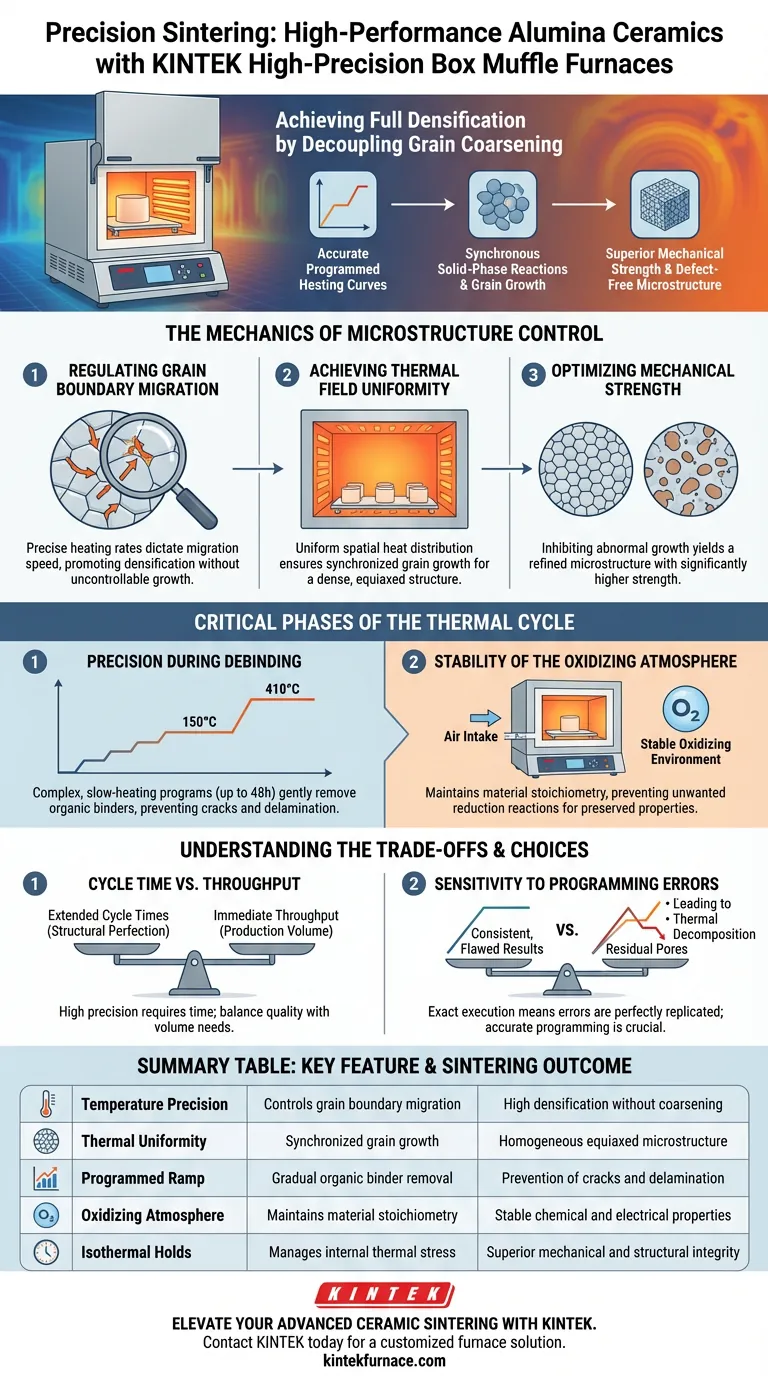

The Mechanics of Microstructure Control

Regulating Grain Boundary Migration

The primary mechanism for ensuring performance is the precise control of heating rates. Accurate programmed heating curves allow operators to dictate the speed of grain boundary migration.

By controlling this rate, the furnace promotes the elimination of pores (densification) without allowing grains to grow uncontrollably. This balance is critical for achieving high mechanical strength in the finished ceramic.

Achieving Thermal Field Uniformity

Beyond simple temperature control, the spatial distribution of heat—the thermal field—must be uniform. A high-precision furnace ensures that every part of the ceramic green body experiences the exact same thermal conditions simultaneously.

This uniformity ensures synchronized grain growth throughout the material. As the ceramic reaches phase transition temperatures, the structure evolves evenly, resulting in a dense, equiaxed grain structure rather than a distorted or uneven one.

Optimizing Mechanical Strength

The ultimate goal of this control is to refine the microstructure. When abnormal grain growth is inhibited, the resulting ceramic possesses a fine, uniform grain structure.

This directly correlates to the material's final properties. A microstructure free of large, abnormal grains and residual porosity exhibits significantly higher mechanical strength and structural integrity.

Critical Phases of the Thermal Cycle

Precision During Debinding

Before final sintering, the furnace plays a vital role in removing organic binders. High-precision furnaces can execute complex debinding programs, sometimes lasting up to 48 hours, with specific isothermal holds (e.g., at 150°C and 410°C).

This slow, uniform heating allows for the gentle decomposition and discharge of organics. Precise regulation minimizes internal stress caused by temperature gradients, effectively preventing cracks or delamination, particularly in thick-walled or large-scale structures.

Stability of the Oxidizing Atmosphere

For oxide ceramics like alumina, the furnace environment is just as critical as the temperature. A box muffle furnace typically utilizes an air atmosphere to provide a stable oxidizing environment.

This atmosphere maintains the material's stoichiometry and prevents unwanted reduction reactions. By preserving the chemical balance of the alumina during sintering, the furnace ensures the material retains its intended physical and electrical properties.

Understanding the Trade-offs

Cycle Time vs. Throughput

Achieving high precision often requires extended cycle times. As noted with debinding programs, the process can take days to ensure organic binders are removed without damaging the structure.

While this guarantees quality, it limits immediate throughput. Operators must balance the need for structural perfection against production volume requirements, accepting that high-performance ceramics cannot be rushed.

Sensitivity to Programming Errors

The capabilities of a high-precision furnace are only as good as the programmed heating curve. Because the furnace follows commands with exactness, an incorrectly calculated ramp rate or hold time will be executed perfectly, leading to consistent but flawed results.

For example, temperatures set too low will result in residual pores and poor densification. Conversely, excessive temperatures can cause thermal decomposition or agglomeration, degrading the material's performance.

Making the Right Choice for Your Goal

To maximize the utility of a high-precision box muffle furnace, align your thermal profile with your specific material requirements:

- If your primary focus is mechanical strength: Prioritize a heating curve that optimizes grain boundary migration rates to achieve full densification without abnormal grain growth.

- If your primary focus is structural integrity of complex shapes: Utilize extended debinding cycles with precise isothermal holds to prevent internal stresses and cracking during binder removal.

- If your primary focus is microstructural consistency: Ensure your loading configuration allows for maximum thermal field uniformity to promote synchronized grain growth across all parts.

Precision in sintering is not just about reaching a target temperature; it is about controlling the entire history of the material's thermal exposure to engineer specific physical properties.

Summary Table:

| Key Feature | Impact on Alumina Ceramics | Sintering Outcome |

|---|---|---|

| Temperature Precision | Controls grain boundary migration | High densification without coarsening |

| Thermal Uniformity | Synchronized grain growth | Homogeneous equiaxed microstructure |

| Programmed Ramp | Gradual organic binder removal | Prevention of cracks and delamination |

| Oxidizing Atmosphere | Maintains material stoichiometry | Stable chemical and electrical properties |

| Isothermal Holds | Manages internal thermal stress | Superior mechanical and structural integrity |

Elevate Your Advanced Ceramic Sintering with KINTEK

Precision is the difference between a flawed part and a high-performance material. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems engineered to deliver the exact thermal control required for sensitive alumina ceramic applications.

Backed by expert R&D and world-class manufacturing, our lab high-temperature furnaces are fully customizable to meet your unique materials science challenges.

Ready to optimize your grain structure and mechanical strength?

Contact KINTEK today for a customized furnace solution

Visual Guide

References

- Wencke Mohring, Christiane Stephan‐Scherb. High-Temperature Corrosion of High- and Medium-Entropy Alloys CrMnFeCoNi and CrCoNi Exposed to a Multi-Oxidant Atmosphere H2O–O2–SO2. DOI: 10.1007/s44210-023-00026-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the main structural components of a muffle furnace? Discover the Engineered System for Contamination-Free Heating

- What are the placement requirements for a muffle furnace? Ensure Safety and Performance in Your Lab

- How does a high-temperature box resistance furnace contribute to the synthesis of silicon-doped ruthenium dioxide catalysts?

- What are the general characteristics and advantages of box type resistance furnaces? Discover Versatile Heating Solutions for Your Lab

- Why is a laboratory muffle furnace necessary for nickel-based superalloys? Expert Stabilization & Hardening Guide

- What is the primary role of a Muffle Furnace in the synthesis of LLZTO? Achieve High-Purity Ceramic Electrolyte Fillers

- What is the critical role of a laboratory high-temperature muffle furnace in TiO2/LDH? Unlock Superior Crystallization

- What role does a muffle furnace play in the preparation of expanded graphite? Achieve Maximum Expansion through Thermal Shock