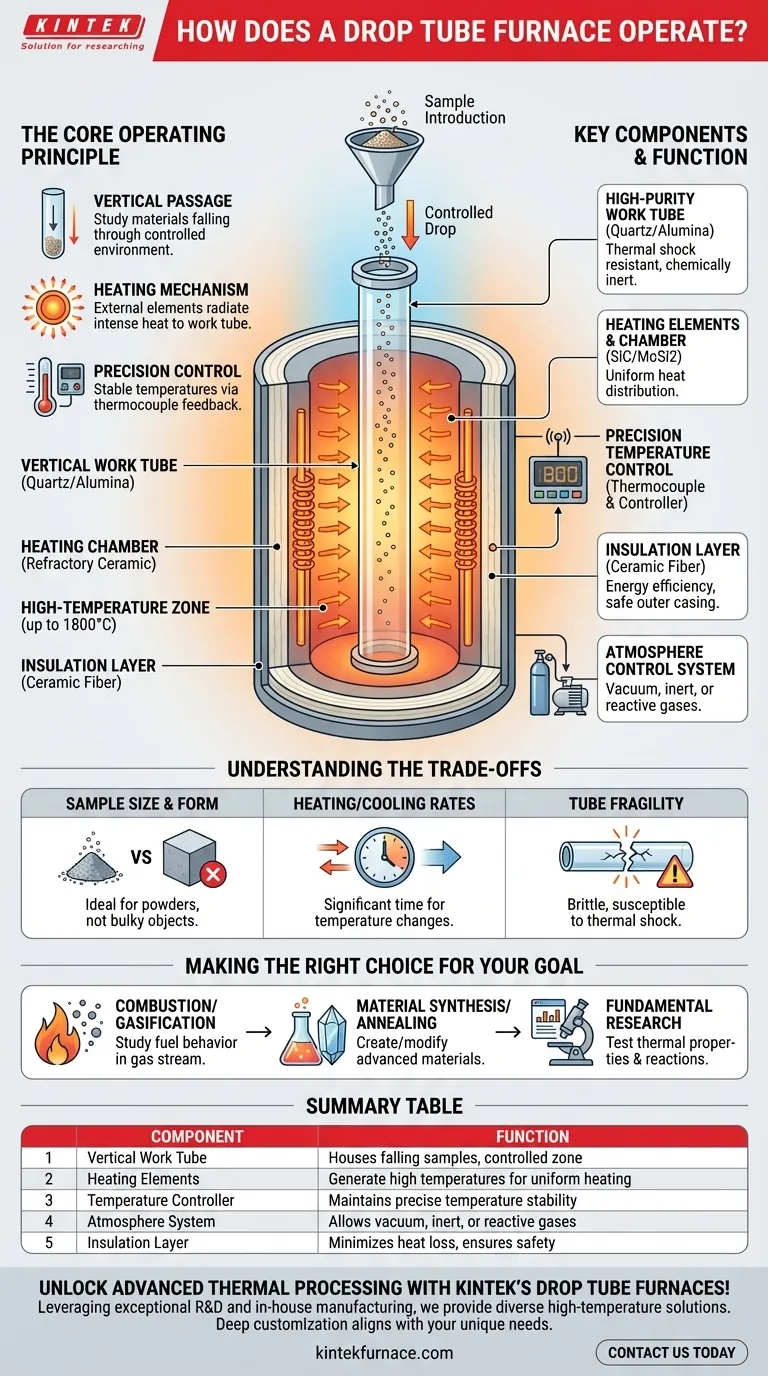

At its core, a drop tube furnace operates by heating materials as they are passed through a vertically oriented tube. This design uses external heating elements to create a precise, high-temperature zone within the tube, allowing for the controlled thermal processing of samples, often under a specific atmosphere like a vacuum or an inert gas.

The defining characteristic of a drop tube furnace is its vertical orientation, which enables the study of materials (especially powders or small particles) as they fall through a controlled temperature and atmospheric environment, simulating processes like combustion or gasification with exceptional precision.

The Core Operating Principle: Controlled Thermal Exposure

A drop tube furnace is an instrument of precision. Its entire design is centered on creating a highly repeatable and tightly controlled heating environment for small samples.

The Vertical Work Tube

The heart of the furnace is the work tube, typically made of a high-purity material like quartz, alumina, or corundum. This tube is mounted vertically or at a steep incline within the main furnace body.

Samples are introduced at the top and either "dropped" to fall through the heated zone or carefully lowered into it. This vertical passage is what distinguishes it from a standard horizontal tube furnace.

The Heating Mechanism

The tube itself is not the source of heat. Instead, it is surrounded by powerful heating elements, such as electrical resistance wires, silicon carbide (SiC) rods, or molybdenum disilicide (MoSi2) rods.

When electricity passes through these elements, they radiate intense heat into the furnace chamber. This heat is transferred uniformly to the work tube and, in turn, to the sample inside.

Precision Temperature Control

To achieve precise temperatures, a thermocouple is placed near the work tube to constantly measure the temperature inside the furnace chamber.

This sensor feeds data back to a digital controller. The controller then adjusts the power sent to the heating elements, maintaining the programmed temperature—which can range from a few hundred to over 1800°C—with remarkable stability.

Key Components and Their Function

Understanding the function of each component reveals why the furnace is so effective for specialized research and processing.

The High-Purity Work Tube

The choice of tube material is critical. Quartz is common for temperatures up to around 1200°C, while ceramic tubes like alumina or corundum are required for higher temperatures. These materials are chosen for their thermal shock resistance and chemical inertness, which prevents contamination of the sample.

Heating Elements and Chamber

The heating elements are housed within a cylindrical heating chamber, typically constructed from high-temperature refractory ceramics. This chamber is engineered to reflect and distribute heat evenly around the work tube.

The Insulation Layer

Surrounding the heating chamber is a thick insulation layer. This layer, made of lightweight ceramic fiber or refractory bricks, minimizes heat loss to the outside environment. This ensures energy efficiency and keeps the outer casing of the furnace cool and safe to the touch.

The Atmosphere Control System

One of the most powerful features is the ability to control the gaseous environment. The work tube is sealed at both ends with flanges that have ports for connecting gas lines and a vacuum pump.

This allows the furnace to operate under a vacuum, an inert atmosphere (like argon or nitrogen to prevent oxidation), or a reactive atmosphere (like oxygen or hydrogen) depending on the experimental requirements.

Understanding the Trade-offs

While powerful, a drop tube furnace is a specialized tool with specific limitations that are important to recognize.

Sample Size and Form

This furnace design is ideal for powders, particulates, and very small solid samples. It is not suitable for processing large, bulky objects due to the limited diameter of the work tube.

Heating and Cooling Rates

The thermal mass of the furnace components means that heating up to the setpoint temperature and cooling back down can take a significant amount of time. The process is not instantaneous, which must be factored into experimental planning.

Tube Fragility

The ceramic or quartz work tubes are brittle and can be susceptible to thermal shock if heated or cooled too quickly. Careful handling and adherence to recommended ramp rates are essential to prevent cracking and failure.

Making the Right Choice for Your Goal

To determine if a drop tube furnace is the correct instrument, consider your primary objective.

- If your primary focus is simulating combustion or gasification: The design is perfect for studying how individual fuel particles (like coal dust or biomass) behave in a controlled, high-temperature gas stream.

- If your primary focus is material synthesis or annealing: The precise atmosphere and temperature control allows you to create or modify advanced materials under highly specific, repeatable conditions.

- If your primary focus is fundamental high-temperature research: The clean, tightly controlled environment is ideal for testing the thermal properties and reactions of small material samples.

Ultimately, the drop tube furnace is a sophisticated instrument that provides researchers and engineers with unparalleled control over the thermal processing of small-scale materials.

Summary Table:

| Component | Function |

|---|---|

| Vertical Work Tube | Houses samples for controlled falling through heated zone, made of quartz or ceramics |

| Heating Elements | Generate high temperatures (up to 1800°C) via electrical resistance for uniform heating |

| Temperature Controller | Maintains precise temperature using thermocouple feedback for stability |

| Atmosphere System | Allows operation under vacuum, inert, or reactive gases to prevent contamination |

| Insulation Layer | Minimizes heat loss, ensuring energy efficiency and safety |

Unlock advanced thermal processing with KINTEK's drop tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs—whether for combustion simulation, material synthesis, or high-temperature research. Contact us today to enhance your lab's precision and efficiency!

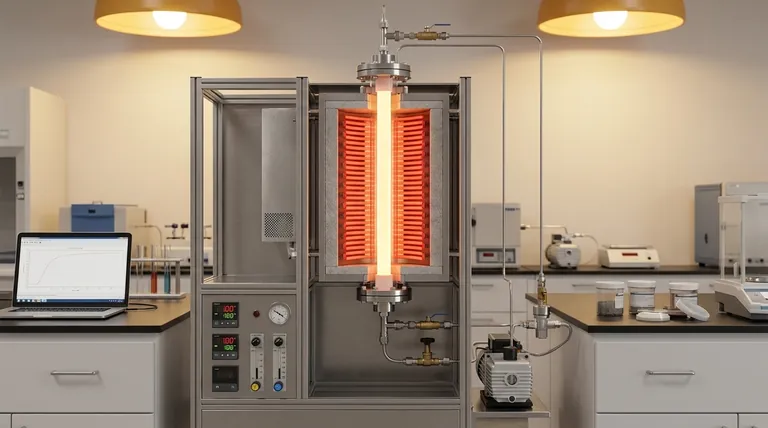

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide