In short, a 10MHz frequency change has a dramatic and often detrimental impact on an MPCVD device. This is not a minor operational tweak; it is a fundamental shift that significantly alters the core physics of the plasma generation process. The change disrupts the electric field, which in turn causes unpredictable variations in the plasma's intensity, shape, and position within the reaction chamber.

An MPCVD system operates as a finely tuned resonant cavity, much like a musical instrument is tuned to a specific note. A seemingly small frequency change of 10MHz is enough to "detune" the entire system, causing the plasma—the engine of the deposition process—to become unstable and inefficient.

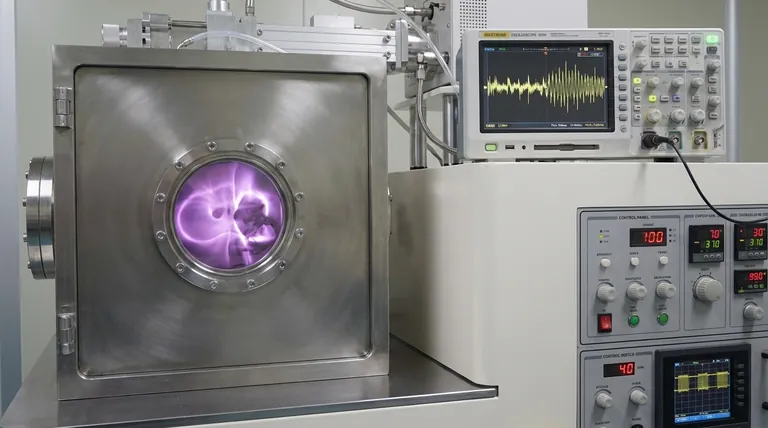

The MPCVD Chamber as a Resonant System

To understand the impact of a frequency shift, you must first view the MPCVD chamber not just as a container, but as a high-precision microwave resonator.

The Principle of Resonance

A resonator is designed to contain and amplify waves of a specific frequency. The physical dimensions of the MPCVD cavity are precisely engineered to match the wavelength of the microwaves being used, typically around 2.45 GHz.

When the frequency is correct, the microwaves form a stable standing wave pattern inside the cavity.

Why Standing Waves Are Critical

A standing wave creates fixed points of maximum and minimum energy. The points of maximum energy, or high electric field strength, are where the energy is concentrated to ignite and sustain the plasma ball.

This stable, predictable high-energy zone is essential for consistent and uniform material deposition, such as diamond growth.

The Cascade Effect of a 10MHz Frequency Shift

Changing the frequency, even by a "small" amount like 10MHz, disrupts this carefully balanced resonant state. This sets off a chain reaction that degrades the process.

Electric Field Disruption

A change in frequency leads to a change in wavelength. The new wavelength no longer perfectly "fits" within the physical dimensions of the cavity.

As a result, the stable standing wave pattern collapses or shifts. The locations of maximum electric field strength become unstable, moving unpredictably within the chamber.

Plasma Intensity and Distribution Changes

The plasma is sustained by the electric field. When the field becomes unstable, the plasma follows suit.

The plasma may change in size, move from its optimal position over the substrate, or flicker in intensity. This means the energy driving the chemical vapor deposition is no longer being delivered effectively or uniformly.

Impact on Deposition Quality

An unstable plasma leads directly to poor deposition results. You will likely observe decreased growth rates, poor material quality (e.g., lower purity diamond), and a lack of uniformity across the substrate.

Understanding the Operational Instability

This extreme sensitivity to frequency is a defining characteristic of resonant cavity systems. Acknowledging this is key to successful operation.

The Myth of "Small" Adjustments

In the context of microwave resonance, there is no such thing as a "small" frequency change. A 10MHz shift relative to a 2.45 GHz source (a change of ~0.4%) is more than enough to completely alter the system's resonant mode.

The Challenge of Process Tuning

This sensitivity is why MPCVD systems require highly stable microwave generators and sophisticated tuning mechanisms (like movable plungers or stubs).

These components are used to either maintain a constant frequency or slightly adjust the cavity's physical geometry to re-establish resonance if the frequency drifts. Any unexpected process variation should immediately point to frequency stability as a potential root cause.

Making the Right Choice for Your Goal

Controlling microwave frequency is not an optional refinement; it is fundamental to a stable and repeatable MPCVD process.

- If your primary focus is process consistency and high-yield production: Invest in a high-stability microwave generator and implement real-time monitoring of the source frequency and reflected power to ensure you are always operating "on resonance."

- If your primary focus is troubleshooting poor or inconsistent deposition results: Make verifying the frequency stability of your microwave source one of your first diagnostic steps. A drifting source is a common and often overlooked cause of failed runs.

Ultimately, mastering the MPCVD process requires treating the microwave frequency as a critical, non-negotiable parameter.

Summary Table:

| Impact Area | Effect of 10MHz Frequency Change |

|---|---|

| Electric Field | Disruption of standing wave pattern, leading to instability |

| Plasma Behavior | Changes in intensity, shape, and position, causing inefficiency |

| Deposition Quality | Decreased growth rates, poor uniformity, and lower material purity |

| Process Stability | Increased risk of failed runs and inconsistent results |

Struggling with unstable MPCVD processes due to frequency shifts? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD systems with robust customization to ensure precise frequency control and plasma stability. Our expertise in R&D and in-house manufacturing helps labs achieve consistent, high-quality diamond growth. Contact us today to optimize your MPCVD setup and enhance your experimental outcomes!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- Why is MPCVD considered a cornerstone of modern materials science and engineering? Unlock High-Purity Materials for Innovation

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth