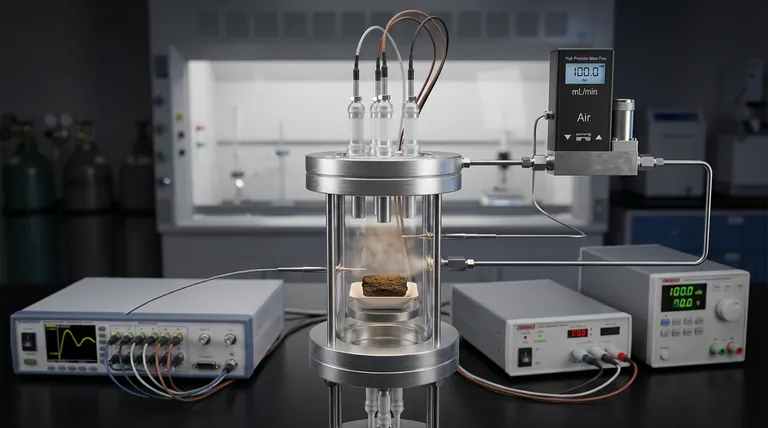

High-precision mass flow controllers (MFCs) act as the foundational tool for studying lignite oxidation by enabling the strict regulation of air flow rates, typically at specific intervals such as 25, 50, 100, and 200 mL/min. By maintaining these exact settings, researchers can deliberately manipulate oxygen diffusion rates and the efficiency of heat removal, allowing them to isolate the variables that drive the chemical changes associated with coal degradation.

Core Insight: The ability to fine-tune gas flow is not just about air supply; it is the primary method for controlling the thermal and chemical environment of the coal sample. This precision is required to accurately correlate ventilation conditions with the evolution of active functional groups and the resulting risk of spontaneous combustion.

The Physics of Oxidation Control

Regulating Oxygen Diffusion

The primary function of a mass flow controller in this context is to define the oxygen diffusion rate. Lignite oxidation is heavily dependent on how much oxygen is available to react with the coal surface.

By setting precise flow rates (e.g., 25 mL/min vs. 200 mL/min), researchers can simulate different ventilation environments. This allows them to observe how rapid or restricted air supply changes the speed and intensity of the oxidation reaction.

Managing Reaction Heat

Oxidation is an exothermic process, meaning it generates heat. However, the airflow that fuels the fire also acts as a cooling agent.

High-precision flow control enables the researcher to manipulate the efficiency of reaction heat removal. This is critical for determining whether the heat generated by oxidation is accumulated within the coal (leading to temperature rise) or dissipated by the air stream.

Chemical Implications and Risk Assessment

Monitoring Functional Groups

The physical parameters of flow directly impact the chemical structure of the lignite. Variations in ventilation affect the content of active functional groups.

Specifically, the presence and concentration of groups such as -CH2- (methylene) and -CH3 (methyl) change based on the airflow conditions. These groups are indicators of the coal's reactivity and its state of degradation.

Predicting Spontaneous Combustion

The ultimate goal of using high-precision MFCs is to evaluate safety risks. By correlating specific flow rates with the changes in functional groups and heat retention, researchers can predict spontaneous combustion risk.

This data helps identify which ventilation conditions create the "perfect storm" for self-heating, moving beyond theoretical models to empirical evidence.

Understanding the Trade-offs

The Ventilation Paradox

When designing these experiments, researchers must account for the dual nature of airflow. Increasing the flow rate increases oxygen supply, which theoretically boosts the reaction.

However, increasing the flow rate also increases convective cooling. There is a critical trade-off where a higher flow rate may actually suppress temperature rise by removing heat faster than it is generated.

Precision vs. Reality

While MFCs offer exact control (e.g., exactly 100 mL/min), real-world coal stockpiles or mines experience fluctuating and uneven airflow.

Researchers must be careful to interpret steady-state lab results as idealized scenarios. The data provides a baseline for risk, but may not perfectly mimic the chaotic ventilation of a physical mine environment.

Making the Right Choice for Your Research

Applying Flow Control to Study Goals

Different research objectives require different focuses when utilizing mass flow controllers.

- If your primary focus is Chemical Kinetics: Prioritize monitoring the changes in -CH2- and -CH3 functional groups across a wide range of flow rates to understand reactivity.

- If your primary focus is Safety Engineering: Focus on the heat removal efficiency at various rates to identify the specific ventilation thresholds that trigger spontaneous combustion.

High-precision flow control turns the complex variable of "ventilation" into a quantifiable data point, enabling precise predictions of lignite behavior.

Summary Table:

| Factor Controlled | Impact on Lignite Research | Key Research Outcome |

|---|---|---|

| Oxygen Diffusion | Regulates reaction speed and intensity | Simulates real-world ventilation scenarios |

| Heat Removal | Manages exothermic heat dissipation vs. accumulation | Identifies spontaneous combustion thresholds |

| Flow Rate Precision | Ensures consistent chemical degradation environments | Accurate monitoring of active functional groups |

| Gas Regulation | Defines the thermal and chemical environment | Quantifies the 'Ventilation Paradox' in safety |

Optimize Your Lignite Research with KINTEK Precision

Precise flow control is the backbone of accurate oxidation analysis. At KINTEK, we understand that reliable data starts with high-quality equipment. Backed by expert R&D and manufacturing, we provide high-performance laboratory solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to meet your unique chemical kinetics and safety engineering needs.

Ready to elevate your lab's capabilities? Contact us today to consult with our experts on the perfect high-temperature furnace or gas control setup for your specific research goals.

References

- Baoshan Jia, Xian Wu. Effects of pre-oxidation temperature and air volume on oxidation thermogravimetric and functional group change of lignite. DOI: 10.1371/journal.pone.0316705

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How do vacuum filtration systems operate in industrial sludge dehydration? Achieve Efficient Liquid-Solid Separation

- How is measurement accuracy maintained for infrared pyrometers? Master Optical Hygiene for High-Temp Metallic Melts

- Which industries can benefit from using the circulating water multifunctional vacuum pump? Discover Clean, Efficient Vacuum Solutions

- How does a high-performance temperature controller contribute to repeatability? Precision for FTO Thin Film Annealing

- Why is a vacuum filtration system necessary before evaluating activated carbon microspheres? Ensure Reliable Test Data

- How does a high-precision analog pressure gauge contribute to the gas delivery system in magnesium combustion experiments?

- What are the technical advantages of using quartz tubes for fiber optic sensors? Optimize High-Temp Performance

- What role do Niobium ampoules play in synthesis? Secure High-Temp Protection for Sensitive Germanium Compounds