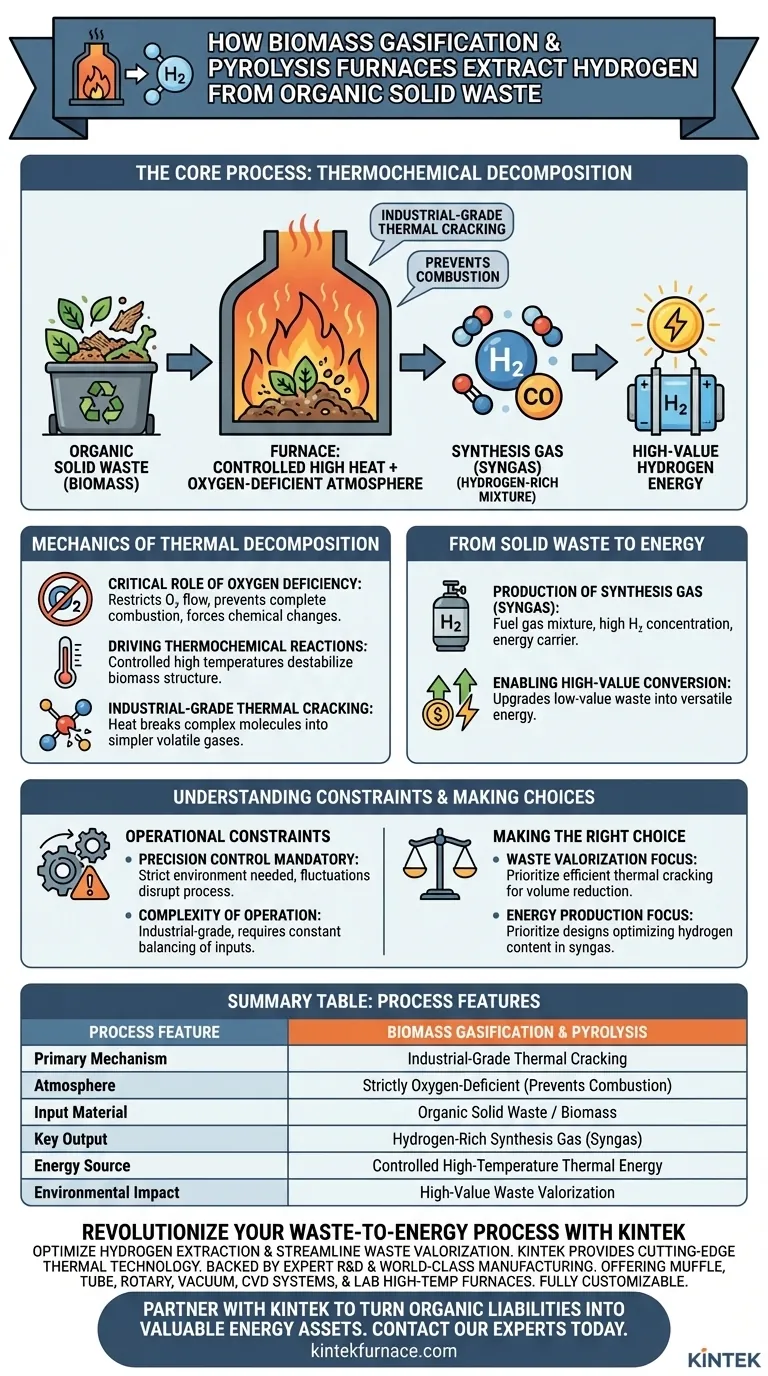

Biomass gasification and pyrolysis furnaces extract hydrogen by subjecting organic solid waste to intense heat within a strictly oxygen-controlled environment. Instead of burning the material, this process triggers industrial-grade thermal cracking, decomposing complex organic matter into a hydrogen-rich mixture known as synthesis gas (syngas).

By maintaining a high-temperature, oxygen-deficient atmosphere, these systems prevent combustion and instead force thermochemical decomposition. This transforms solid organic waste into high-value hydrogen energy through the production of syngas.

The Mechanics of Thermal Decomposition

To understand how hydrogen is extracted from solid waste, one must look at the specific environmental conditions created inside the furnace.

The Critical Role of Oxygen Deficiency

The defining characteristic of these furnaces is an oxygen-deficient environment.

Unlike incineration, which floods waste with oxygen to burn it, these systems restrict oxygen flow.

This prevents the organic material from combusting completely, forcing it to undergo chemical changes rather than simply burning into ash and smoke.

Driving Thermochemical Reactions

The process relies on controlled high temperatures to drive the system.

Heat acts as the energy source that destabilizes the chemical structure of the biomass.

This thermal energy forces the solid matter to break down at a molecular level.

Industrial-Grade Thermal Cracking

The combination of heat and low oxygen results in thermal cracking.

Complex organic molecules found in waste are "cracked" or broken apart into simpler molecules.

This decomposition releases volatile gases that were previously trapped within the solid structure.

From Solid Waste to Energy

Once the physical breakdown occurs, the focus shifts to the resulting chemical output.

Production of Synthesis Gas (Syngas)

The direct output of this decomposition is synthesis gas, commonly referred to as syngas.

Syngas is a fuel gas mixture that contains a high concentration of hydrogen.

It serves as the carrier medium, effectively transferring the energy potential of the solid waste into a gaseous state.

Enabling High-Value Conversion

The ultimate goal of this process is the creation of high-value hydrogen energy.

By extracting hydrogen via syngas, the system upgrades low-value organic waste into a versatile energy carrier.

This allows for the utilization of waste streams that would otherwise be discarded.

Understanding the Constraints

While this technology offers a pathway to renewable hydrogen, it is important to recognize the inherent operational requirements.

Precision Control is Mandatory

Success depends entirely on maintaining a strictly controlled environment.

Fluctuations in temperature or oxygen levels can disrupt the thermal cracking process or lead to unwanted combustion.

Complexity of Operation

These are industrial-grade processes, implying a level of complexity higher than standard waste disposal.

Operators must constantly balance thermal inputs against the volume of organic waste to ensure consistent syngas production.

Making the Right Choice for Your Goals

To determine if this technology aligns with your operational objectives, consider your primary outcome.

- If your primary focus is waste valorization: Look for systems that emphasize the efficiency of thermal cracking to maximize the reduction of solid waste volume.

- If your primary focus is energy production: Prioritize furnace designs that optimize the hydrogen content within the resulting syngas for higher energy yields.

Ultimately, these furnaces serve as a bridge, using heat and chemistry to transmute solid organic liabilities into valuable hydrogen assets.

Summary Table:

| Process Feature | Biomass Gasification & Pyrolysis |

|---|---|

| Primary Mechanism | Industrial-Grade Thermal Cracking |

| Atmosphere | Strictly Oxygen-Deficient (Prevents Combustion) |

| Input Material | Organic Solid Waste / Biomass |

| Key Output | Hydrogen-Rich Synthesis Gas (Syngas) |

| Energy Source | Controlled High-Temperature Thermal Energy |

| Environmental Impact | High-Value Waste Valorization |

Revolutionize Your Waste-to-Energy Process with KINTEK

Are you looking to optimize hydrogen extraction or streamline waste valorization? KINTEK provides the cutting-edge thermal technology required for precise thermochemical decomposition. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temp furnaces—all fully customizable to meet your unique industrial or research needs.

Partner with KINTEK to turn organic liabilities into valuable energy assets.

Contact Our Technical Experts Today

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What makes rotary furnaces suitable for continuous production? Unlock High-Volume Efficiency & Uniformity

- What are the scale and efficiency advantages of shaft furnace vs. rotary kiln for DRI? Maximize Your Production Output

- What are the advantages of using rotary tube furnaces for CVD applications? Achieve Uniform Coatings for Powders

- What customization options are available for rotary tube furnaces? Tailor Your Furnace for Precise Thermal Processing

- What is a rotary furnace and what is its basic shape? Discover Its Cylindrical Design for Efficient Heat Treatment

- What are the primary advantages of pyrolysis rotary kiln reactors? Achieve Superior Waste-to-Resource Conversion

- What is a Rotary Tube Tilt Furnace and how does it differ from traditional static furnaces? Achieve Uniform Heating for Powders and Granules

- What role do control systems play in rotary furnaces? Unlock Precision and Efficiency in Materials Processing