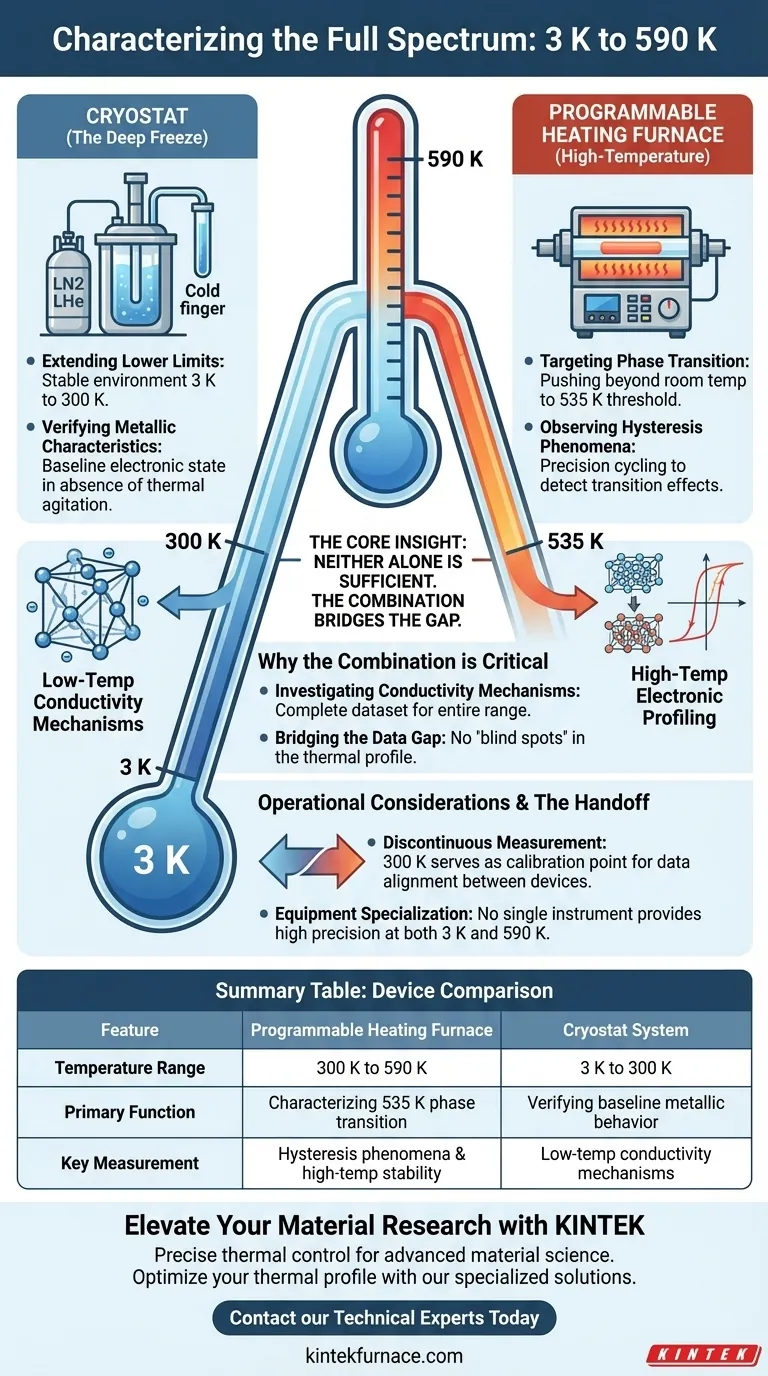

To characterize the full resistivity profile of NaRu2O4, a precision programmable heating furnace and a cryostat function as complementary thermal stages that cover opposite ends of the temperature spectrum. The furnace manages the high-temperature environment from 300 K to 590 K, while the cryostat extends measurement capabilities down to cryogenic levels as low as 3 K.

The Core Insight Neither device alone provides the necessary bandwidth to fully understand the electronic properties of NaRu2O4. By utilizing both, researchers can effectively bridge the gap between near-zero temperatures and high heat, capturing critical phase transitions and verifying metallic behavior across the entire physical range.

The Role of the Programmable Heating Furnace

Targeting the Critical Phase Transition

The primary function of the heating furnace is to push the material beyond room temperature limits. This is specifically required to reach the 535 K threshold, where NaRu2O4 undergoes a significant metal-to-metal phase transition.

Observing Hysteresis Phenomena

Precision control is vital in this upper range. The programmable nature of the furnace allows researchers to carefully ramp temperatures up and down around the 535 K mark. This controlled cycling is the only way to accurately detect and measure hysteresis phenomena associated with the transition.

The Role of the Cryostat

Extending the Lower Limits

While the furnace handles heat, the cryostat is responsible for the "deep freeze." It provides a stable environment for measurements ranging from room temperature down to 3 K.

Verifying Fundamental Metallic Characteristics

Investigating the material at these cryogenic temperatures is essential for establishing its baseline electronic state. Data collected in this range allows researchers to confirm the metallic characteristics of NaRu2O4 in the absence of thermal agitation.

Why the Combination is Critical

Investigating Conductivity Mechanisms

To understand how NaRu2O4 conducts electricity, researchers need a complete dataset. The combination of these two devices allows for the investigation of conductivity mechanisms across a massive thermal range.

Bridging the Data Gap

Using both tools ensures there are no "blind spots" in the thermal profile. This comprehensive coverage is necessary to validate theoretical models regarding how the material behaves as it moves from a cold, stable metallic state to a high-temperature transition phase.

Operational Considerations

Equipment Specialization vs. Versatility

It is important to recognize that this measurement strategy requires a "handoff" between devices. There is no single instrument capable of maintaining high precision at both 3 K and 590 K simultaneously.

The Necessity of Discontinuous Measurement

Because two separate environments are used, researchers must align the data carefully. The overlapping range near room temperature (approx. 300 K) serves as the calibration point where data from the cryostat ends and data from the furnace begins.

Making the Right Choice for Your Goal

To maximize the utility of your setup, align your equipment focus with the specific physical property you intend to isolate.

- If your primary focus is characterizing the phase transition: Prioritize the programmable furnace's stability around 535 K to accurately map hysteresis loops.

- If your primary focus is establishing baseline electronic properties: rely on the cryostat to verify metallic behavior and conductivity mechanisms at temperatures approaching absolute zero.

By integrating these two specialized thermal environments, you ensure a rigorous and complete analysis of the temperature-dependent resistivity of NaRu2O4.

Summary Table:

| Feature | Programmable Heating Furnace | Cryostat System |

|---|---|---|

| Temperature Range | 300 K to 590 K | 3 K to 300 K |

| Primary Function | Characterizing 535 K phase transition | Verifying baseline metallic behavior |

| Key Measurement | Hysteresis phenomena & high-temp stability | Low-temp conductivity mechanisms |

| Operational Goal | High-heat electronic profiling | Deep-freeze baseline analysis |

Elevate Your Material Research with KINTEK

Precise thermal control is the backbone of advanced material science. Whether you are mapping phase transitions in NaRu2O4 or investigating fundamental electronic states, KINTEK provides the specialized equipment needed for high-accuracy results.

Backed by expert R&D and world-class manufacturing, we offer:

- Precision Muffle and Tube Furnaces for stable high-temperature cycles.

- Customizable Vacuum and CVD Systems tailored to your specific atmosphere requirements.

- Advanced Rotary and Lab Furnaces designed for uniform heating and durability.

Don't let equipment limitations create blind spots in your data. Our customizable high-temperature solutions are engineered to help researchers and industrial partners achieve peak performance.

Ready to optimize your thermal profile? Contact our technical experts today to discuss your unique project needs.

Visual Guide

References

- Anna Scheid, Peter A. van Aken. Direct Evidence of Anomalous Peierls Transition-Induced Charge Density Wave Order at Room Temperature in Metallic NaRu2O4. DOI: 10.1093/mam/ozae129

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the application of box type annealing atmosphere furnace in automotive parts manufacturing? Boost Performance and Efficiency

- What types of gases are commonly used in atmosphere furnaces and why? Optimize Your Heat Treatment Process

- How does a reactive rapid thermal annealing furnace contribute to phosphosulfide crystallization? Expert Insights

- What are sealed atmosphere furnaces called and what are their features? Discover Precision Heat Treatment Solutions

- What are the operational considerations for a controlled atmosphere furnace? Master Key Factors for Material Processing

- What industries commonly use low vacuum atmosphere furnaces? Key Sectors for Cost-Effective Heat Treatment

- How does a reactor integrated within a box furnace maintain a controlled environment? Precise Calcination Control

- What are the five key components of atmosphere furnaces? Master Controlled Heat Treatment for Superior Results