To operate a controlled atmosphere furnace effectively, you must focus on three core areas: meticulous management of the process gases, precise control over temperature cycles, and strict adherence to safety protocols. Success hinges on understanding that the furnace is a complete system where the atmosphere, temperature, and material interact to produce a desired outcome.

A controlled atmosphere furnace is not merely a box that gets hot. It is a precision instrument for engineering material properties. Mastering its operation means moving beyond simply setting a temperature and instead controlling the entire reactive environment within the chamber.

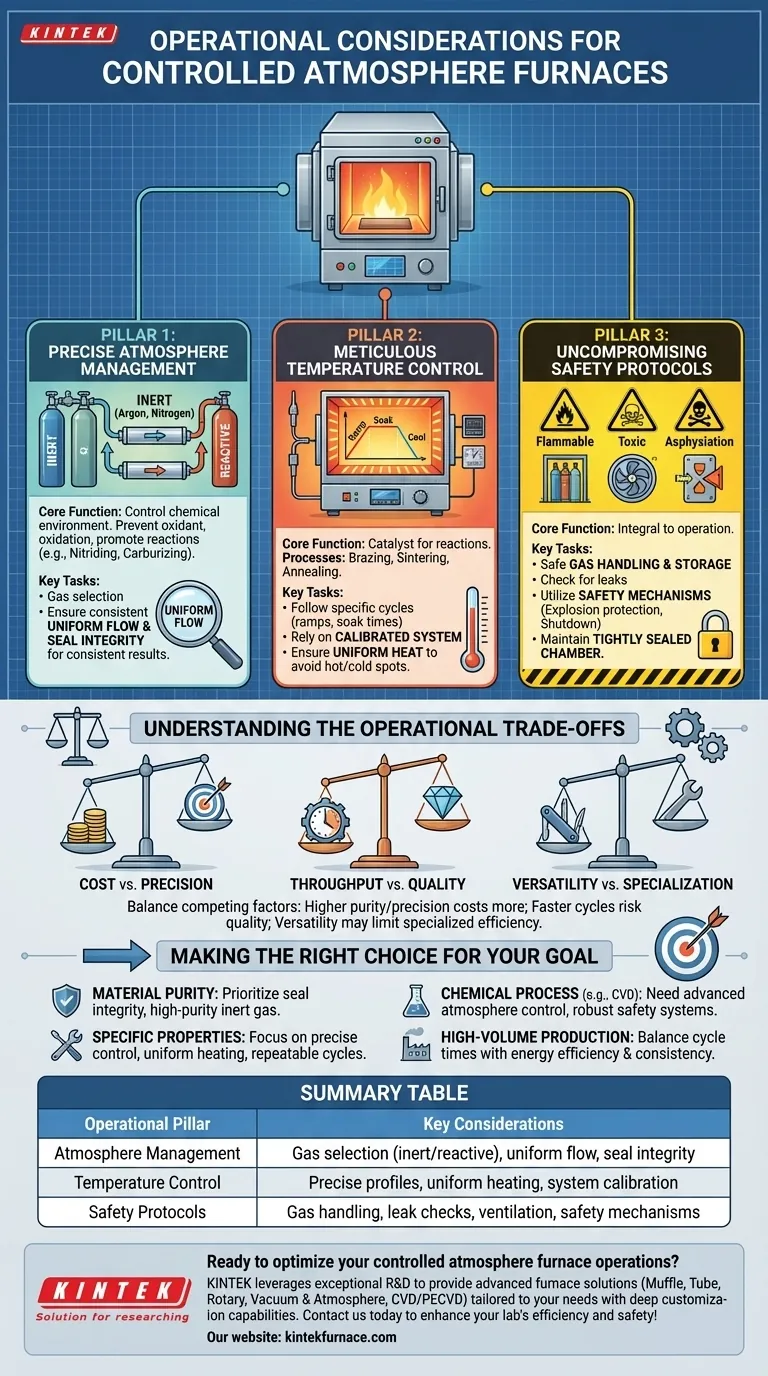

The Three Pillars of Furnace Operation

Effective operation stands on three critical pillars. Neglecting any one of them can lead to failed processes, damaged equipment, or serious safety incidents.

Pillar 1: Precise Atmosphere Management

The entire purpose of this furnace is to control the chemical environment. This is your primary operational task.

The atmosphere's function is to prevent undesirable reactions, like oxidation from ambient air, or to promote desirable ones, like in nitriding or carburizing.

Gas selection is paramount. Inert gases like argon or nitrogen are used to create a protective, non-reactive environment. Reactive gases are used to actively change the surface chemistry of the material being processed.

Your operational control comes from the gas inlet and outlet systems. You must ensure a consistent, uniform flow of gas throughout the chamber to guarantee every part of your material is exposed to the same conditions. A poor seal or non-uniform flow will create inconsistencies in your final product.

Pillar 2: Meticulous Temperature Control

Temperature is the catalyst that drives the reactions enabled by your controlled atmosphere.

Different processes require unique temperature profiles. Brazing, sintering, and annealing each have specific temperature ramps, soak times, and cooling rates that must be followed precisely to achieve the desired material properties.

Operationally, this means relying on the temperature control system, which uses thermocouples to measure temperature and controllers to adjust power to the heating elements. You must trust, but also verify, that your system is calibrated and performing accurately.

The heating chamber's design and the condition of the heating elements are key. They must provide uniform heat to prevent hot or cold spots that could ruin the part or batch.

Pillar 3: Uncompromising Safety Protocols

Controlled atmospheres often involve gases that are flammable, toxic, or pose an asphyxiation risk. Safety is not an option; it is an integral part of the operation.

You must have established procedures for handling and storing gas cylinders. This includes securing cylinders, checking for leaks, and ensuring proper ventilation in the furnace area.

Modern furnaces include critical safety mechanisms like explosion protection devices for flammable gases and automated shutdown systems. Never bypass these features.

A tightly sealed chamber is as much a safety feature as it is a process requirement. It prevents hazardous process gases from leaking into the laboratory or production floor and prevents air from leaking in, which could create a fire or explosion risk with certain atmospheres.

Understanding the Operational Trade-offs

Every operational decision involves balancing competing factors. Understanding these trade-offs is the mark of an expert operator.

Cost vs. Precision

Higher-purity gases and more sophisticated atmosphere control systems deliver superior results but come at a higher operational cost. You must determine the level of precision your process truly requires.

Throughput vs. Quality

Faster heating and cooling cycles can increase production throughput. However, rushing these ramps can induce thermal stress, leading to warped parts or incomplete chemical processes. The ideal cycle is often a compromise between speed and metallurgical perfection.

Versatility vs. Specialization

A furnace designed to handle many different atmospheres and processes is versatile but may not be as efficient or effective for a single, high-volume task as a specialized unit. For example, the materials used for heating elements must be compatible with the process gas, limiting a single furnace's range.

Making the Right Choice for Your Goal

Your operational strategy should be directly guided by your end goal.

- If your primary focus is material purity and preventing oxidation: Prioritize a furnace with excellent seal integrity and a high-purity inert gas delivery system.

- If your primary focus is achieving specific material properties (e.g., hardness): Concentrate on precise temperature control, uniform heating, and repeatable process cycles.

- If your primary focus is a chemical process (e.g., CVD): You need advanced atmosphere control to manage gas mixtures and flow rates, along with robust safety systems for reactive precursor gases.

- If your primary focus is high-volume production: Balance cycle times with energy efficiency and product consistency to reduce operating costs and maximize output.

Ultimately, successful operation is about viewing the furnace, atmosphere, and material as a single, interconnected system and controlling it with precision.

Summary Table:

| Operational Pillar | Key Considerations |

|---|---|

| Atmosphere Management | Gas selection (inert/reactive), uniform flow, seal integrity |

| Temperature Control | Precise profiles, uniform heating, system calibration |

| Safety Protocols | Gas handling, leak checks, ventilation, safety mechanisms |

Ready to optimize your controlled atmosphere furnace operations? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and safety!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment