In automotive manufacturing, a box-type annealing atmosphere furnace is primarily used for the critical heat treatment of high-performance engine components. Its most prominent application is the tempering of high-carbon steel valve springs, a process that imparts the necessary strength and elasticity for them to withstand millions of cycles in a high-speed engine environment.

The core value of this furnace is not simply heating metal; it's the ability to precisely manipulate a material's internal structure in a controlled, protective atmosphere. This ensures that automotive parts achieve the exact mechanical properties required for extreme reliability and performance, without surface degradation.

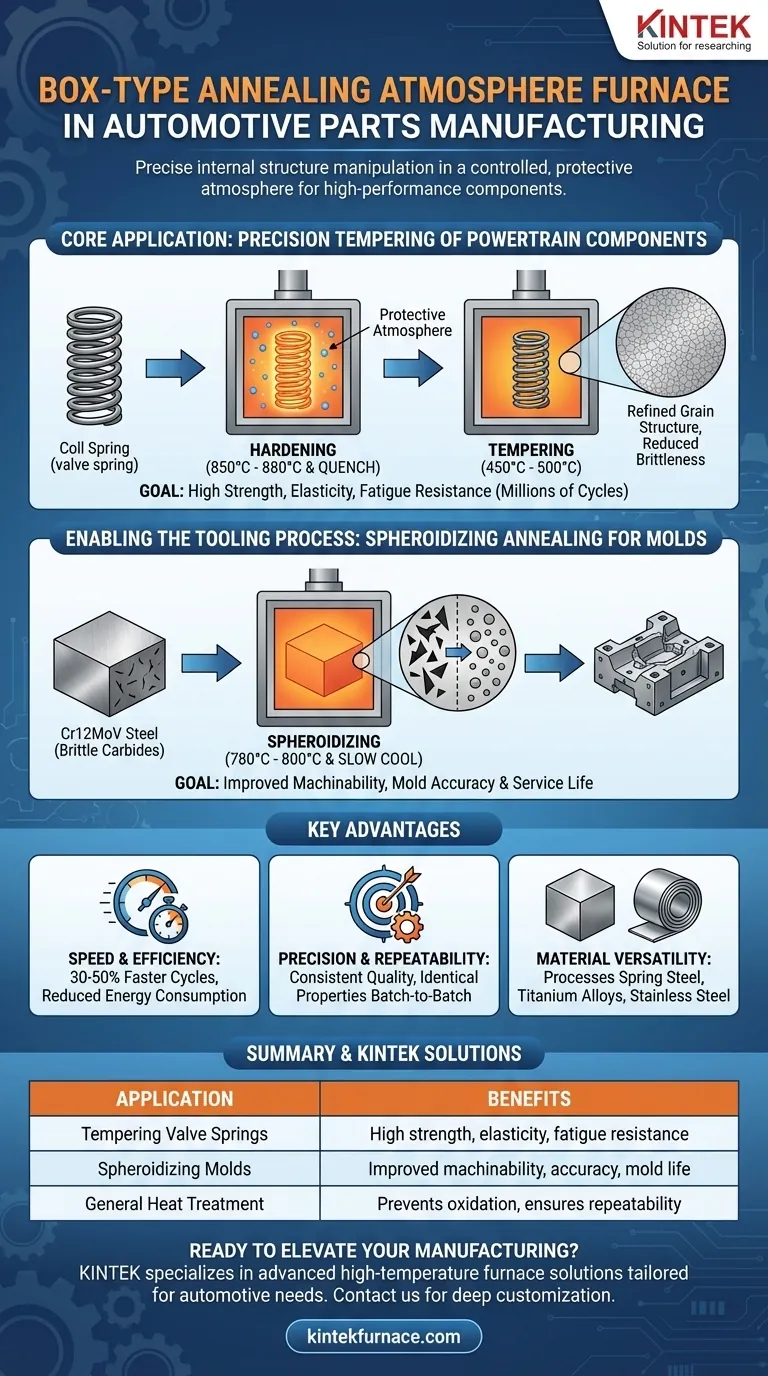

The Core Application: Precision Tempering of Powertrain Components

The most direct use of this technology in automotive part production is for post-quenching heat treatment, specifically tempering. This refines the metal's grain structure after it has been hardened.

How It Works: The Valve Spring Example

The process for a component like a valve spring is highly specific. First, the high-carbon spring steel is heated to between 850°C and 880°C and then rapidly cooled by quenching in oil.

Following this hardening step, the spring is tempered in the box furnace at a lower temperature, typically 450°C to 500°C.

The Engineering Goal: High Strength and Elasticity

This two-stage heat treatment process is designed to create an optimal balance of properties. The initial hardening creates strength, while the subsequent tempering reduces brittleness and establishes a high elastic limit.

This ensures the spring can compress and expand millions of times without deforming or failing, a non-negotiable requirement for modern engine reliability and longevity.

The Role of a Controlled Atmosphere

The "atmosphere" aspect of the furnace is critical. The controlled internal environment, often composed of inert or specific reactive gases, prevents oxidation and decarburization on the part's surface during heating. This preserves the integrity of the material and ensures consistent performance.

Beyond Parts: Enabling the Automotive Tooling Process

The furnace's application extends beyond the final parts and into the tools and dies used to make them. This is a crucial, often overlooked, aspect of the manufacturing supply chain.

Spheroidizing Annealing for Mold Steel

For manufacturing molds from steels like Cr12MoV, the furnace is used for spheroidizing annealing. This involves heating the steel to 780°C to 800°C, holding it for several hours, and then cooling it very slowly.

The Impact on Manufacturing Quality

This process transforms hard, brittle carbides in the steel into small, rounded particles. The result is a softer, more uniform material with vastly improved machinability.

This not only makes it easier to create complex and precise molds but also prepares the steel for its final hardening treatment, ultimately enhancing the accuracy and service life of the mold.

Understanding the Key Advantages

Automotive manufacturing is a demanding industry where efficiency, quality, and cost are paramount. The box-type atmosphere furnace offers distinct advantages that meet these needs.

Speed and Efficiency

Compared to older furnace designs, modern box-type units can shorten annealing and tempering cycles by 30% to 50%. This is due to faster heating rates and superior insulation, which also reduces overall energy consumption.

Precision and Repeatability

The ability to tightly control both temperature and atmosphere composition is essential for meeting the strict quality standards of the automotive industry. This precision ensures that every part in a batch—and every batch over time—has identical mechanical properties.

Material Versatility

While its use on spring steel is a classic example, this furnace is also essential for processing modern materials used in lightweighting and high-performance applications. This includes annealing and brazing treatments for titanium alloys and various grades of stainless steel.

Making the Right Choice for Your Goal

To leverage this technology effectively, you must align its capabilities with your specific manufacturing objective.

- If your primary focus is producing high-fatigue life components: The furnace is essential for the tempering process to achieve the required strength and elasticity in parts like springs, shafts, and gears.

- If your primary focus is improving tooling and mold-making: Use spheroidizing annealing to enhance the machinability of mold steels, leading to higher precision and longer-lasting tools.

- If your primary focus is overall process efficiency: The key benefits are reduced cycle times, lower energy costs, and the high degree of repeatability needed for high-volume, zero-defect production.

Ultimately, this furnace is a cornerstone technology for creating the robust, reliable, and high-performance metal components that define the modern automobile.

Summary Table:

| Application | Key Process | Temperature Range | Benefits |

|---|---|---|---|

| Tempering Valve Springs | Post-quenching heat treatment | 450°C to 500°C | High strength, elasticity, fatigue resistance |

| Spheroidizing Annealing for Molds | Heating and slow cooling | 780°C to 800°C | Improved machinability, mold accuracy, and service life |

| General Heat Treatment | Controlled atmosphere processing | Varies by material | Prevents oxidation, ensures repeatability, reduces cycle times |

Ready to elevate your automotive manufacturing with precision heat treatment? KINTEK specializes in advanced high-temperature furnace solutions, including Box-Type Atmosphere Furnaces, tailored for automotive parts and tooling. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique needs—whether for tempering engine components or annealing mold steels. Contact us today to discuss how our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems can enhance your efficiency and product quality!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing