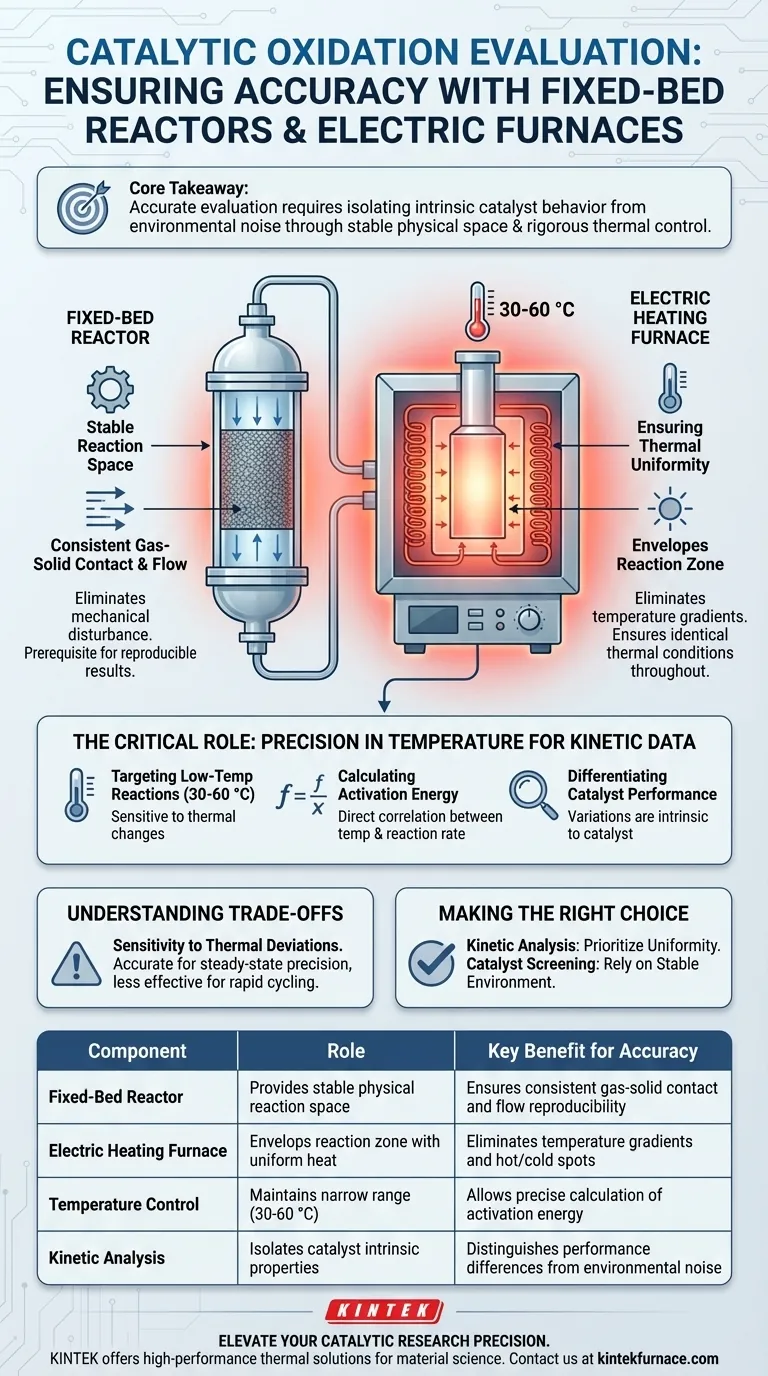

Measurement accuracy in catalytic evaluation relies on stabilizing the physical environment and rigorously controlling thermal conditions. A fixed-bed reactor and an electric heating furnace work in tandem to eliminate experimental variables. The reactor provides a consistent physical space for the reaction, while the furnace maintains a precise and uniform temperature profile, ensuring that the data collected reflects true chemical kinetics rather than environmental fluctuations.

Core Takeaway To accurately evaluate hydrogen isotope oxidation, you must isolate the catalyst's intrinsic behavior from external noise. By pairing a fixed-bed reactor with a high-precision electric furnace, researchers can achieve the thermal uniformity required to calculate activation energy and reliably distinguish performance differences between catalysts.

The Foundation of Accurate Measurement

To generate reliable data for hydrogen isotope oxidation, you must control both the physical state of the catalyst and the energy supplied to the reaction.

Providing a Stable Reaction Space

The fixed-bed reactor acts as the anchor for the experiment. Its primary function is to provide a stable space where the catalytic reaction can occur without mechanical disturbance.

By securing the catalyst bed, the reactor ensures that the gas flow interacts consistently with the solid material. This physical stability is the prerequisite for reproducible results.

Ensuring Thermal Uniformity

The electric heating furnace complements the reactor by enveloping the reaction zone in a controlled thermal environment. Its role is to ensure the temperature remains highly uniform throughout the catalyst bed.

Any temperature gradient—hot spots or cold spots—within the reactor would distort the reaction rate. The furnace eliminates this variable, ensuring the entire catalyst bed operates under identical thermal conditions.

The Critical Role of Temperature Control

Precision in temperature is not just about stability; it is the key to unlocking kinetic data.

Targeting Low-Temperature Reactions

This setup is particularly effective for evaluating low-temperature oxidation reactions, typically operating in the range of 30-60 °C.

At these lower temperatures, reactions are highly sensitive to thermal changes. The electric furnace provides the fine-grained control necessary to maintain these specific conditions without overshooting.

Calculating Activation Energy

The ultimate goal of this precision is to determine the activation energy of the reaction.

Accurate calculation of activation energy requires a direct correlation between temperature and reaction rate. If the temperature fluctuates, the kinetic data becomes noisy and unreliable.

Differentiating Catalyst Performance

When screening multiple catalysts, you need to know that performance differences are real.

Because the furnace maintains a strict temperature profile, researchers can be confident that variations in output are due to the intrinsic properties of the catalyst, not inconsistencies in the heating equipment.

Understanding the Trade-offs

While this system offers high accuracy, it relies heavily on the performance limits of the heating element.

Sensitivity to Thermal Deviations

The system's accuracy is entirely dependent on the furnace's ability to maintain uniformity within the 30-60 °C window.

If the furnace calibration drifts or if it cannot maintain uniformity at such low temperatures, the evaluation of activation energy will be compromised. The system is designed for steady-state precision, meaning it may be less effective in scenarios requiring rapid temperature cycling.

Making the Right Choice for Your Goal

When designing your experimental setup for hydrogen isotope oxidation, consider your specific analytical needs.

- If your primary focus is Kinetic Analysis: Prioritize the furnace's ability to maintain thermal uniformity to ensure accurate calculation of activation energy.

- If your primary focus is Catalyst Screening: Rely on the fixed-bed reactor's stable environment to eliminate variables, allowing for a fair comparison of performance differences between materials.

Precision in the reaction environment is the only path to data you can trust.

Summary Table:

| Component | Role in Evaluation | Key Benefit for Accuracy |

|---|---|---|

| Fixed-Bed Reactor | Provides stable physical reaction space | Ensures consistent gas-solid contact and flow reproducibility |

| Electric Heating Furnace | Envelops reaction zone with uniform heat | Eliminates temperature gradients and hot/cold spots |

| Temperature Control | Maintains narrow range (30-60 °C) | Allows precise calculation of activation energy |

| Kinetic Analysis | Isolates catalyst intrinsic properties | Distinguishes performance differences from environmental noise |

Elevate Your Catalytic Research Precision

Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of material science. Our customizable lab high-temp furnaces provide the thermal uniformity and stability essential for calculating activation energy and screening catalysts with absolute confidence.

Ready to optimize your reaction environment? Contact us today to discuss how our specialized thermal solutions can deliver the reliable data your research deserves.

Visual Guide

References

- Guilin Wei, Xingwen Feng. Embedding Monodisperse LaO <i> <sub>x</sub> </i> Into Pt Nanoclusters for Ultra‐Stable and Efficient Hydrogen Isotope Oxidation. DOI: 10.1002/advs.202504224

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a high-precision furnace required for carbon aerogel activation? Achieve Optimal Pore Development & Control

- What role does helium play in nanoparticle synthesis? Unlock Precision via Inert Gas Condensation

- What role does a releasing agent play during the assembly process of titanium-steel composite plates?

- What role does temperature control play in biomass pyrolysis for biochar? Achieve Optimal Pore Structure & Yield

- What is the purpose of using a precision oven for HAp-Fe3O4 drying? Achieve 110°C Stability & High Porosity

- How does the SCRS model simplify furnace combustion simulation? Efficiency Meets Accuracy in Thermal Modeling

- What is the significance of high-precision temperature monitoring systems in SPS? Control Ti-6Al-4V/HA Microstructure

- What is the significance of a laboratory vacuum drying oven in the treatment of hybrid membranes? | Optimize Performance