Programmable muffle furnaces serve as the primary validation tool for ensuring the longevity of solar absorption materials. They are utilized to create rigorous, controlled thermal environments that subject nanolayer structures to the exact heating curves and prolonged high temperatures found in Concentrated Solar Thermal (CST) systems.

By enabling precise ramp rates and extended isothermal aging, these furnaces generate the reliability data needed to predict how nanostructures will chemically and physically survive in high-temperature air environments.

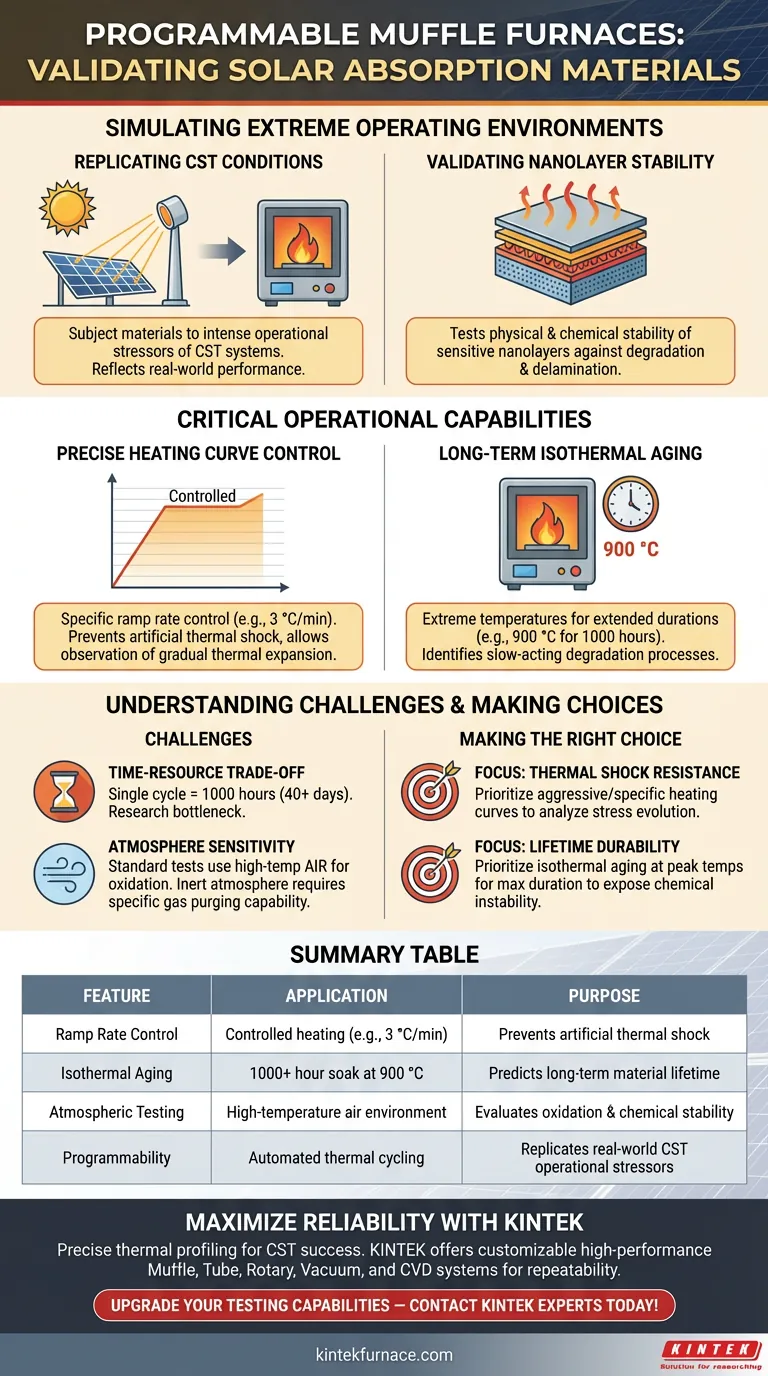

Simulating Extreme Operating Environments

Replicating CST Conditions

Concentrated Solar Thermal (CST) systems operate under intense thermal stress. To validate materials for this use, researchers must move beyond standard heating.

They use programmable furnaces to simulate the exact operational stressors a material will face in the field. This ensures that the data collected reflects real-world performance rather than theoretical best-case scenarios.

Validating Nanolayer Stability

Solar absorption materials often consist of complex nanolayer structures. These structures are highly sensitive to thermal fluctuations and oxidative stress.

The muffle furnace tests the physical and chemical stability of these nanostructures. The goal is to ensure they do not degrade or delaminate when exposed to the harsh thermal cycles typical of solar energy generation.

Critical Operational Capabilities

Precise Heating Curve Control

The durability of a material is not just about the maximum temperature it can withstand; it is also about how it gets there.

Programmable furnaces allow for specific ramp rate control, such as a steady increase of 3 °C/min. This slow, controlled heating prevents artificial thermal shock, allowing researchers to observe how the material handles gradual thermal expansion.

Long-Term Isothermal Aging

Short-term tests cannot predict long-term failure modes. Therefore, these furnaces are programmed for extensive isothermal aging.

Materials are subjected to extreme temperatures, such as 900 °C, for durations up to 1000 hours. This marathon testing capability is essential for identifying slow-acting degradation processes that would be missed during shorter experiments.

Understanding the Challenges

The Time-Resource Trade-off

The primary limitation of this testing method is the significant time investment required.

Running a single durability cycle for 1000 hours means a furnace is occupied for over 40 days. This creates a bottleneck in the research pipeline, requiring careful scheduling and potentially multiple units to maintain throughput.

Atmosphere Sensitivity

While many muffle furnaces can control heating rates, the specific test described here relies on a high-temperature air environment.

This is intended to test oxidation resistance. However, if your material requires an inert atmosphere (to prevent oxidation completely), you must ensure the specific furnace unit supports gas purging, as not all standard muffle furnaces have this capability.

Making the Right Choice for Your Goal

To effectively utilize a programmable muffle furnace for solar material testing, align your programming with your specific data requirements:

- If your primary focus is Thermal Shock Resistance: Prioritize the programming of aggressive or specific heating curves (e.g., the 3 °C/min ramp) to analyze stress evolution during temperature changes.

- If your primary focus is Lifetime Durability: Prioritize isothermal aging at peak operating temperatures (e.g., 900 °C) for maximum duration to expose long-term chemical instability.

The value of the programmable muffle furnace lies not just in generating heat, but in the rigorous repeatability of that heat over geological timeframes.

Summary Table:

| Feature | Application in Solar Testing | Purpose |

|---|---|---|

| Ramp Rate Control | Controlled heating (e.g., 3 °C/min) | Prevents artificial thermal shock |

| Isothermal Aging | 1000+ hour soak at 900 °C | Predicts long-term material lifetime |

| Atmospheric Testing | High-temperature air environment | Evaluates oxidation & chemical stability |

| Programmability | Automated thermal cycling | Replicates real-world CST operational stressors |

Maximize Your Solar Research Reliability with KINTEK

Precise thermal profiling is the difference between material failure and long-term success in Concentrated Solar Thermal (CST) systems. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your specific ramp rates and isothermal aging requirements.

Whether you need precision air-environment testing or gas-purged systems for inert atmosphere control, our lab high-temp furnaces provide the repeatability your nanolayer research demands.

Upgrade your testing capabilities—Contact KINTEK experts today!

Visual Guide

References

- Yifan Guo, Juan F. Torres. Scalable nano-architecture for stable near-blackbody solar absorption at high temperatures. DOI: 10.1038/s41467-023-44672-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What function does a high-temperature muffle furnace serve in the preparation of Ni-doped LaFeO3 gas-sensing materials?

- What types of applications are muffle furnaces commonly used for? Essential Uses in Material Analysis, Heat Treatment, and Synthesis

- What temperature does a muffle furnace control? From 100°C to 1800°C+ for Your Specific Process

- What temperature ranges are available for box furnaces? Find the Perfect Fit for Your Thermal Processes

- What role does a high-temperature muffle furnace play in the electrodeposition of high-purity iron? Achieve Precision

- What electrical precautions should be taken when setting up a muffle furnace? Essential Safety Tips for Your Lab

- What are the standard features of box furnaces? Unlock Precision and Efficiency in Thermal Processing

- What insulation materials are used in muffle furnaces? Choose the Best for Heat Efficiency and Durability