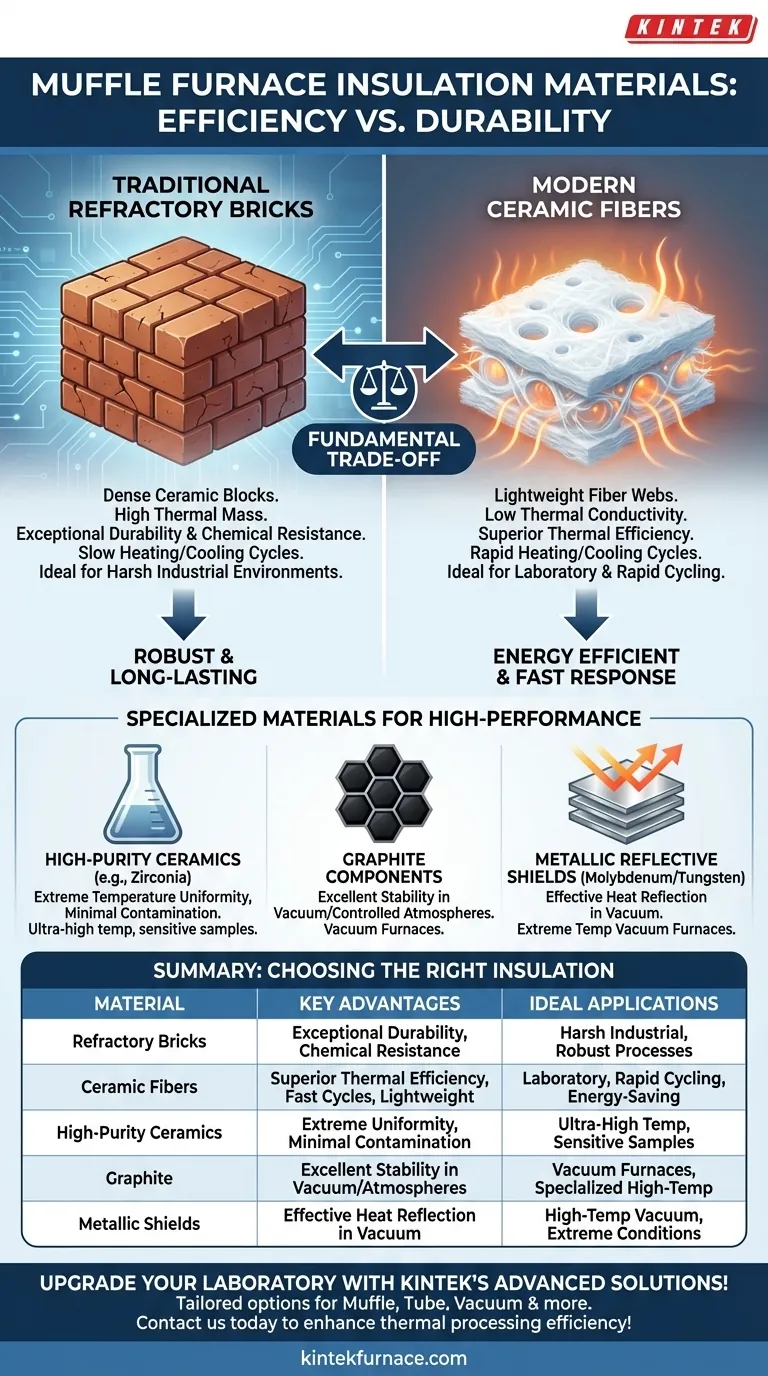

In a muffle furnace, insulation is primarily achieved using two distinct classes of materials: traditional, dense refractory bricks or modern, lightweight ceramic fibers. While both serve to contain heat, they represent fundamentally different approaches to thermal management, each with specific advantages for different applications.

The choice between refractory bricks and ceramic fibers is a fundamental trade-off. Bricks offer exceptional durability and chemical resistance, while ceramic fibers provide superior thermal efficiency, faster heating and cooling cycles, and a significantly lighter overall furnace construction.

The Two Pillars of Muffle Furnace Insulation

At its core, the insulation in a muffle furnace dictates its performance characteristics, including energy consumption, heating speed, and temperature stability. The material choice reflects the intended use of the furnace.

Traditional Refractory Bricks

Refractory bricks are dense, heavy ceramic blocks that have been the standard for decades. They work by absorbing and containing a massive amount of thermal energy.

These materials are known for their exceptional physical durability and high resistance to chemical attack, making them ideal for harsh industrial environments.

However, their high thermal mass means they take a long time and a significant amount of energy to heat up and cool down, making them less efficient for processes requiring rapid temperature changes.

Modern Ceramic Fibers

Ceramic fibers are a newer class of insulation, often formed into lightweight boards, blankets, or molded shapes. These materials consist of a web of fibers with a high volume of trapped air.

This structure gives them extremely low thermal conductivity, allowing them to insulate effectively with much less mass than bricks.

A key advantage is their low thermal mass, which enables very rapid heating and cooling cycles. This dramatically improves energy efficiency and process throughput in laboratory settings.

Specialized Materials for High-Performance Applications

For more demanding or specialized environments, such as vacuum furnaces or ultra-high temperature work, advanced materials are employed.

High-Purity Ceramic Grades

For applications requiring extreme temperature uniformity or chemical inertness, high-purity fibers are used. Zirconia-grade ceramic fiber, for example, offers excellent performance at very high temperatures and minimizes potential contamination of sensitive samples.

Graphite Components

In certain controlled-atmosphere or vacuum furnaces, graphite in the form of wafers or felt is used as an insulation or heating element. It offers excellent high-temperature stability in the absence of oxygen.

Metallic Reflective Shields

Some high-temperature vacuum furnaces use a different insulation strategy altogether. They employ multiple layers of reflective shields, typically made of molybdenum or tungsten.

Instead of absorbing heat, these shields reflect thermal radiation back into the heating zone. This is a highly effective method for achieving extreme temperatures with minimal heat loss in a vacuum.

Understanding the Trade-offs: Efficiency vs. Durability

The choice of insulation is not just about material science; it's about operational priorities. Understanding the inherent compromises is key to selecting the right furnace.

Thermal Mass and Energy Use

A furnace lined with dense refractory bricks has high thermal mass. It acts like a thermal "flywheel," requiring significant energy to reach its operating temperature.

A ceramic fiber furnace has very low thermal mass. It heats up quickly with far less energy input, making it much more efficient for non-continuous use.

Heat-Up and Cool-Down Rates

The low mass of ceramic fiber allows for dramatically faster process cycles. A furnace can be brought to temperature, used, and cooled down in a fraction of the time required for a brick-lined unit.

Longevity and Contamination

Refractory bricks are robust and can withstand significant physical abuse and direct chemical exposure.

Ceramic fibers, while durable, can be more susceptible to mechanical damage. In certain clean environments, there can also be a concern about microscopic fiber shedding over the furnace's lifetime.

Making the Right Choice for Your Application

Selecting a furnace requires matching the insulation type to your primary goal.

- If your primary focus is rapid cycling and energy efficiency: Choose a furnace with ceramic fiber insulation for its fast response times and lower power consumption.

- If your primary focus is process durability and chemical resistance: A furnace lined with dense refractory bricks is the more robust and long-lasting choice for harsh environments.

- If your primary focus is ultra-high temperatures or vacuum processes: Look for specialized designs using high-purity ceramic grades or metallic heat shields tailored for those conditions.

Ultimately, understanding the insulation material allows you to select a furnace that is not just a heater, but a precise tool optimized for your specific thermal processing needs.

Summary Table:

| Material Type | Key Advantages | Ideal Applications |

|---|---|---|

| Refractory Bricks | Exceptional durability, high chemical resistance | Harsh industrial environments, processes requiring robustness |

| Ceramic Fibers | Superior thermal efficiency, fast heating/cooling, lightweight | Laboratory settings, rapid cycling, energy-saving processes |

| High-Purity Ceramics (e.g., Zirconia) | Extreme temperature uniformity, minimal contamination | Ultra-high temperature work, sensitive sample processing |

| Graphite | Excellent stability in vacuum/controlled atmospheres | Vacuum furnaces, specialized high-temperature applications |

| Metallic Reflective Shields | Effective heat reflection in vacuum, minimal heat loss | High-temperature vacuum furnaces, extreme temperature conditions |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met precisely. Contact us today to enhance your thermal processing efficiency and performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the temperature of a muffle oven? A Guide to Choosing the Right Range for Your Lab

- What makes box furnaces versatile equipment? Unlock Adaptable Heating for Diverse Applications

- How does a muffle furnace with a weighing system benefit biochar research? Gain Real-Time Pyrolysis Insights

- Why is a muffle furnace utilized for primary heat treatment at 250 °C? Optimize Your Perovskite Catalyst Structure

- What industries commonly use muffle furnaces for high-temperature testing? Essential Tools for Materials Science, Chemistry, and More

- How does muffle furnace temperature affect coconut husk biochar? Optimize Crystallinity and Yield

- How are muffle furnaces utilized in high-temperature sintering within the pharmaceutical industry? Unlock Precision in Drug Delivery and Implants

- What core role does a high-temperature box resistance furnace play in the production of doped Nickel Oxide nanopowders?