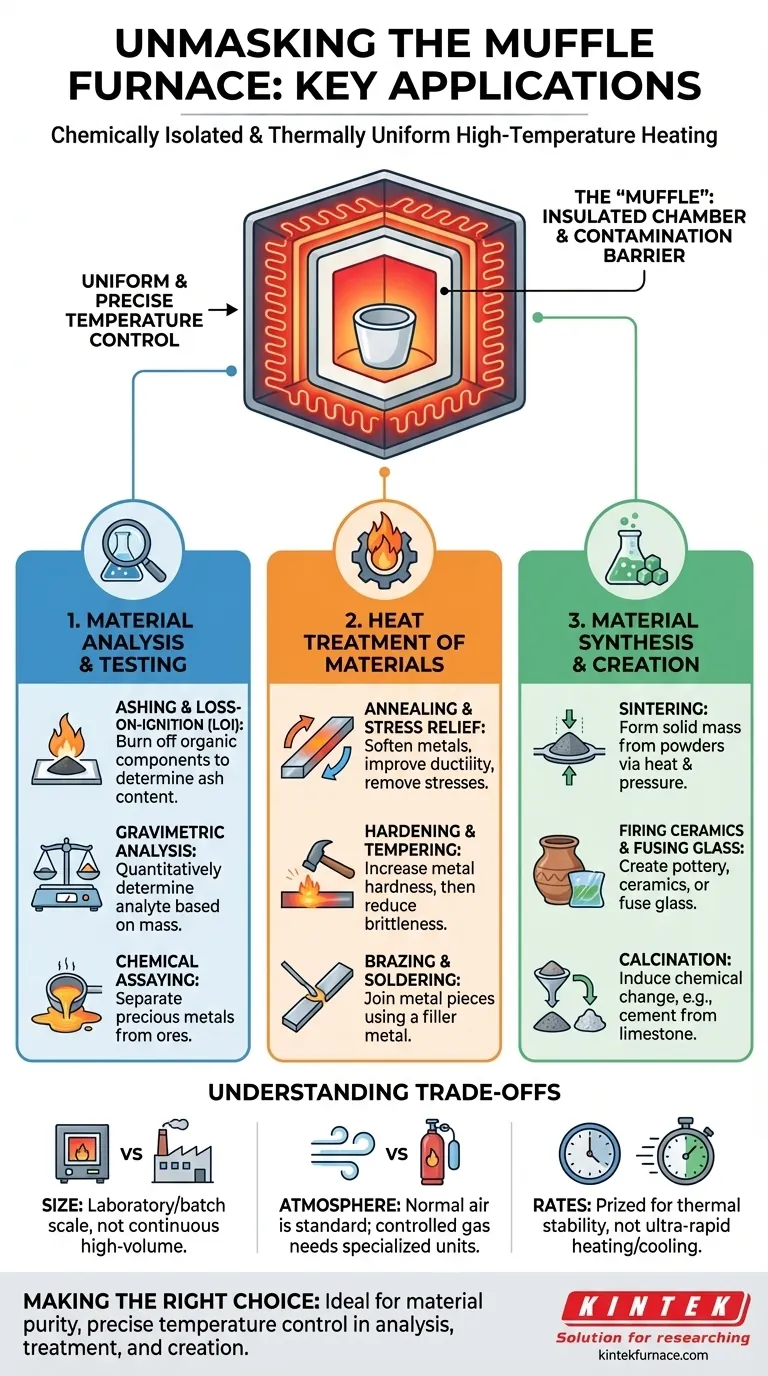

In essence, a muffle furnace is a high-temperature oven used for a wide range of applications where a sample must be heated without being contaminated by the heating source. Its most common uses fall into three primary categories: analyzing the composition of materials, heat-treating metals to alter their properties, and synthesizing new materials like ceramics or fused glass.

A muffle furnace's core value is not just its high heat, but its ability to provide a chemically isolated and thermally uniform environment. This makes it an indispensable tool for any process where material purity and precise temperature control are non-negotiable.

The Core Principle: Why a "Muffle"?

Before listing applications, it is critical to understand what makes this furnace unique. The name itself reveals its function.

The Insulated Chamber (The "Muffle")

A muffle furnace contains a primary chamber, or "muffle," made of a high-temperature, non-corrosive material like ceramic fiber. This chamber holds the sample.

Preventing Contamination

The heating elements are located outside this muffle. This design completely separates the material being heated from any byproducts of combustion or direct radiation from the electric elements, ensuring the sample's chemical purity is maintained.

Uniform and Precise Temperature Control

This separation, combined with heavy insulation, allows for an exceptionally uniform and stable temperature throughout the chamber. This is crucial for processes that are sensitive to thermal gradients.

Application Category 1: Material Analysis and Testing

A primary use for muffle furnaces is to determine the composition of a substance by seeing what remains after intense heating.

Ashing and Loss-on-Ignition (LOI)

This is perhaps the most common analytical use. A sample is weighed, heated in the furnace to burn off all organic and volatile components, and then weighed again.

The remaining material is the ash content, which is critical for quality control in industries like food, plastics, coal, and pharmaceuticals. The weight difference represents the loss-on-ignition.

Gravimetric Analysis

This is a broader category that includes ashing. It involves quantitatively determining an analyte based on its mass. The furnace is used to convert a substance into a form that can be accurately weighed.

Chemical Assaying

In mining and metallurgy, muffle furnaces are used in assaying to separate precious metals like gold and silver from their ores for measurement. The high, controlled heat is essential for the chemical reactions involved in this separation.

Application Category 2: Heat Treatment of Materials

Muffle furnaces are fundamental tools for altering the physical and mechanical properties of metals and other materials.

Annealing and Stress Relief

Annealing involves heating a metal to a specific temperature and then cooling it slowly. This process softens the metal, makes it easier to work with, and improves its ductility. A similar process, stress relief, removes internal stresses caused by manufacturing.

Hardening and Tempering

Hardening requires heating steel to a high temperature and then cooling it rapidly (quenching). This makes the metal harder but also more brittle. Tempering is a subsequent, lower-temperature heating process that reduces that brittleness while retaining most of the hardness.

Brazing and Soldering

These processes join metal pieces together using a filler metal that has a lower melting point than the base metals. The uniform heat of a muffle furnace is ideal for ensuring the filler metal flows evenly into the joint.

Application Category 3: Material Synthesis and Creation

The furnace is also a creative tool, used to form solid materials from powders or other precursors.

Sintering

Sintering is the process of compacting and forming a solid mass of material by heat and pressure without melting it to the point of liquefaction. It is widely used to create ceramic parts, metal components, and other powder metallurgy products.

Firing Ceramics and Fusing Glass

The controlled, predictable heating cycles of a muffle furnace are perfect for firing pottery and ceramics, where temperature must be increased and decreased at a precise rate to prevent cracking. Similarly, it's used for fusing pieces of glass together in art and manufacturing.

Calcination

Calcination involves heating a solid material to a high temperature to induce a chemical change, often by driving off a volatile component like carbon dioxide or water. A common example is the production of cement clinker from limestone.

Understanding the Trade-offs

While incredibly versatile, muffle furnaces are not the right tool for every high-temperature job.

Size and Batch Processing

Most muffle furnaces are designed for laboratory or small-scale batch work. They are generally not suited for continuous, high-volume industrial production lines, where a tunnel or conveyor furnace would be more appropriate.

Atmosphere Control

A standard muffle furnace operates with a normal air atmosphere. While this is fine for many applications like ashing, some processes (like heat-treating certain reactive metals) require an inert or controlled gas atmosphere. Furnaces with this capability are specialized and more costly.

Heating and Cooling Rates

Muffle furnaces are prized for their thermal stability. While they can reach high temperatures, they are not typically designed for extremely rapid heating or cooling cycles, which can stress the ceramic muffle.

Making the Right Choice for Your Goal

To determine if a muffle furnace fits your need, consider your end goal.

- If your primary focus is determining the inorganic content of a sample: A muffle furnace is the standard tool for ashing and loss-on-ignition analysis.

- If your primary focus is altering the properties of a metal part: A muffle furnace provides the precise temperature control needed for annealing, hardening, and tempering.

- If your primary focus is creating a solid object from powder or clay: A muffle furnace is ideal for sintering materials or firing ceramics due to its uniform heat.

Ultimately, the muffle furnace is a cornerstone of materials science, providing a clean, stable, and precise high-temperature environment for analysis, treatment, and creation.

Summary Table:

| Application Category | Key Processes | Common Industries |

|---|---|---|

| Material Analysis | Ashing, Gravimetric Analysis, Chemical Assaying | Food, Pharmaceuticals, Mining, Metallurgy |

| Heat Treatment | Annealing, Hardening, Tempering, Brazing | Metalworking, Manufacturing |

| Material Synthesis | Sintering, Firing Ceramics, Calcination | Ceramics, Glass, Powder Metallurgy |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable muffle, tube, rotary, vacuum & atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs for material analysis, heat treatment, or synthesis. Contact us today to discuss how our tailored solutions can enhance your processes and deliver superior results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production