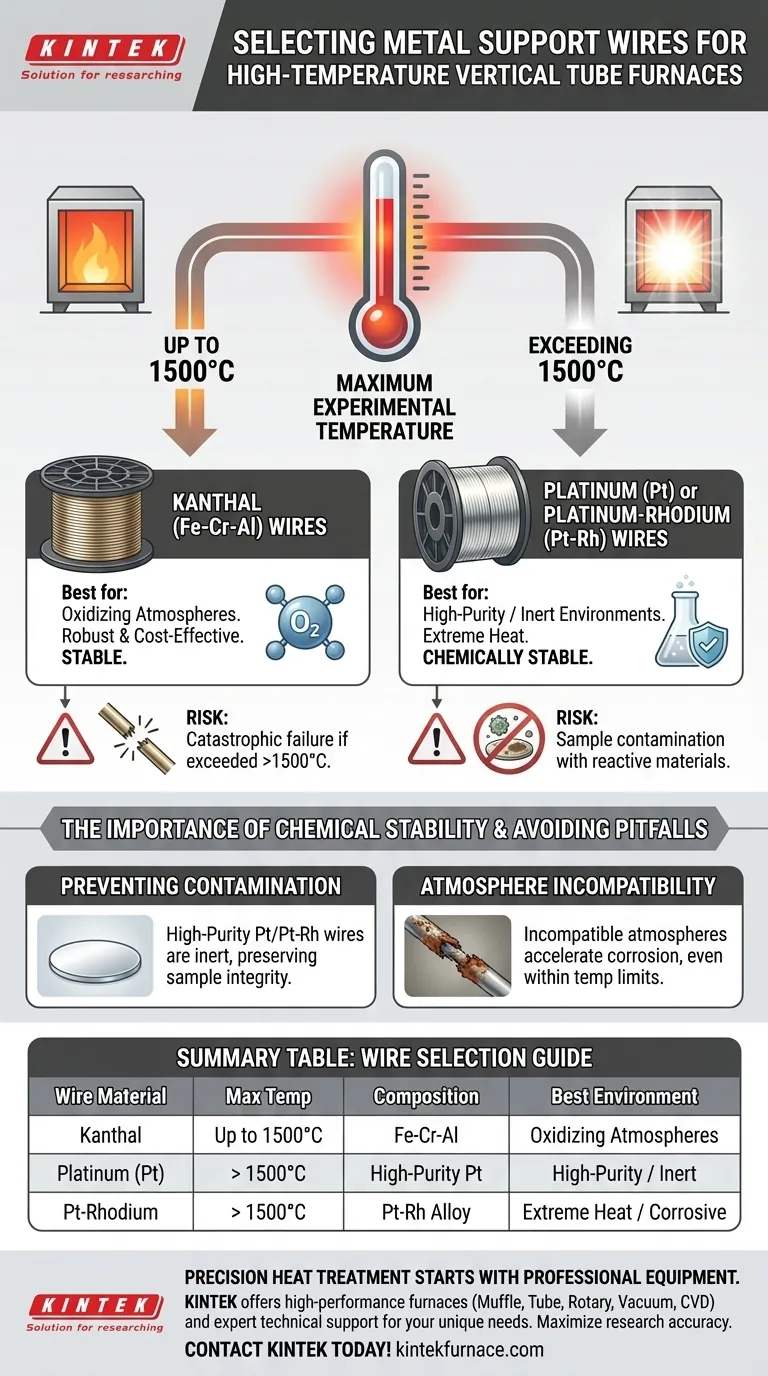

The selection of metal support wires is dictated primarily by the maximum experimental temperature and the chemical environment of the furnace. For applications reaching up to 1500°C, Kanthal (Fe-Cr-Al) alloy wires are the standard choice due to their stability in oxidizing atmospheres. However, when experiments exceed 1500°C, you must switch to high-purity platinum (Pt) or platinum-rhodium (Pt-Rh) wires to prevent melting and sample contamination.

Matching the wire alloy to your specific temperature zone is not just about structural integrity; it is essential for preventing chemical interaction between the support and your sample.

Temperature-Based Material Selection

The primary criterion for choosing a suspension wire is the thermal limit of the experiment. The uniform hot zone of a vertical tube furnace places extreme stress on materials, necessitating a strict adherence to temperature thresholds.

Applications Up to 1500°C

For experiments conducted below this threshold, Kanthal wires are the optimal solution.

These wires are composed of an Iron-Chromium-Aluminum (Fe-Cr-Al) alloy. They are specifically engineering to remain stable in oxidizing atmospheres, making them a robust choice for standard high-temperature procedures.

Applications Exceeding 1500°C

Once the temperature rises above 1500°C, ferrous alloys are no longer viable.

For these extreme conditions, Platinum (Pt) or Platinum-Rhodium (Pt-Rh) wires are required. These materials possess significantly higher melting points, allowing them to maintain structural integrity where other alloys would fail.

The Importance of Chemical Stability

Beyond the melting point, the chemical interaction between the wire and the furnace environment is a critical factor.

Preventing Sample Contamination

At high temperatures, materials become more reactive. A wire that degrades or off-gases can destroy the validity of your sample data.

High-purity Platinum and Platinum-Rhodium wires offer superior chemical stability. This inertness ensures that the wire does not react with the sample or the atmosphere, preserving the purity of your experiment.

Common Pitfalls to Avoid

Selecting the wrong wire is often a result of underestimating the impact of the specific furnace atmosphere or temperature spikes.

The Risk of Wire Failure

Using Kanthal wires beyond their 1500°C limit is a common error that leads to catastrophic failure.

If the wire melts or loses tensile strength, the suspended sample will drop, potentially damaging the furnace tube and ruining the experiment.

Atmosphere Incompatibility

While Kanthal is noted for stability in oxidizing atmospheres, it is vital to verify that your chosen wire material is compatible with the specific atmosphere control required for your furnace.

Incompatible atmospheres can accelerate corrosion or embrittlement, leading to premature wire snapping even if the temperature is within the theoretical limit.

Making the Right Choice for Your Goal

To ensure the safety of your equipment and the accuracy of your results, match your wire selection to your specific operational parameters.

- If your primary focus is standard high-temperature oxidizing experiments (<1500°C): Utilize Kanthal (Fe-Cr-Al) wires for a cost-effective and stable suspension solution.

- If your primary focus is extreme heat (>1500°C) or high purity: Mandate the use of Platinum (Pt) or Platinum-Rhodium (Pt-Rh) wires to ensure the wire withstands the thermal load without contaminating the sample.

Select your suspension material with the same rigor you apply to your sample preparation to guarantee reproducible, uncontaminated results.

Summary Table:

| Wire Material | Max Operating Temp | Alloy Composition | Best Environment |

|---|---|---|---|

| Kanthal | Up to 1500°C | Fe-Cr-Al | Oxidizing Atmospheres |

| Platinum (Pt) | > 1500°C | High-Purity Pt | High-Purity / Inert |

| Pt-Rhodium | > 1500°C | Pt-Rh Alloy | Extreme Heat / Corrosive |

Precision Heat Treatment Starts with Professional Equipment

Ensure the integrity of your high-temperature experiments with the right setup. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory needs. Whether you are working with standard oxidizing atmospheres or extreme heat exceeding 1500°C, our technical team is ready to help you select the perfect furnace and accessories.

Maximize your research accuracy—contact KINTEK today for a consultation!

Visual Guide

References

- Georgii Khartcyzov, Evgueni Jak. Integrated Experimental and Thermodynamic Modelling Study of Phase Equilibria in the PbO-AlO1.5-SiO2 System in Air. DOI: 10.1007/s12540-024-01878-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is a heating element and its key components? Discover How It Powers Efficient Heat Generation

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are high-performance microwave-absorbing materials required in microwave sintering? Solve the 'Cold Start' Challenge

- What are the primary advantages of Molybdenum Disilicide (MoSi2) heating elements? Unmatched High-Temp Performance & Lifespan

- What are the properties and uses of tungsten as a high-temperature heating element? Unlock Extreme Heat Up to 2500°C

- Why is high temperature stability important for graphite heating elements? Ensure Reliable Performance in Extreme Heat

- What are the applications of MoSi2 heating elements in the chemical industry? Unlock High-Temp Precision for Synthesis and More

- How has molybdenum been used in industrial furnaces as a heating element? Unlock High-Temp Performance Up to 1900°C