Picture this: weeks of preparation, a valuable and carefully prepared sample, and a meticulously planned heating cycle. You wait for hours as the furnace completes its run and cools down. You open the chamber, expecting a pristine, perfectly synthesized material. Instead, you find a discolored, oxidized, or structurally flawed sample. The experiment is a failure. Again. Time, resources, and morale are all wasted, and you're left wondering what went wrong.

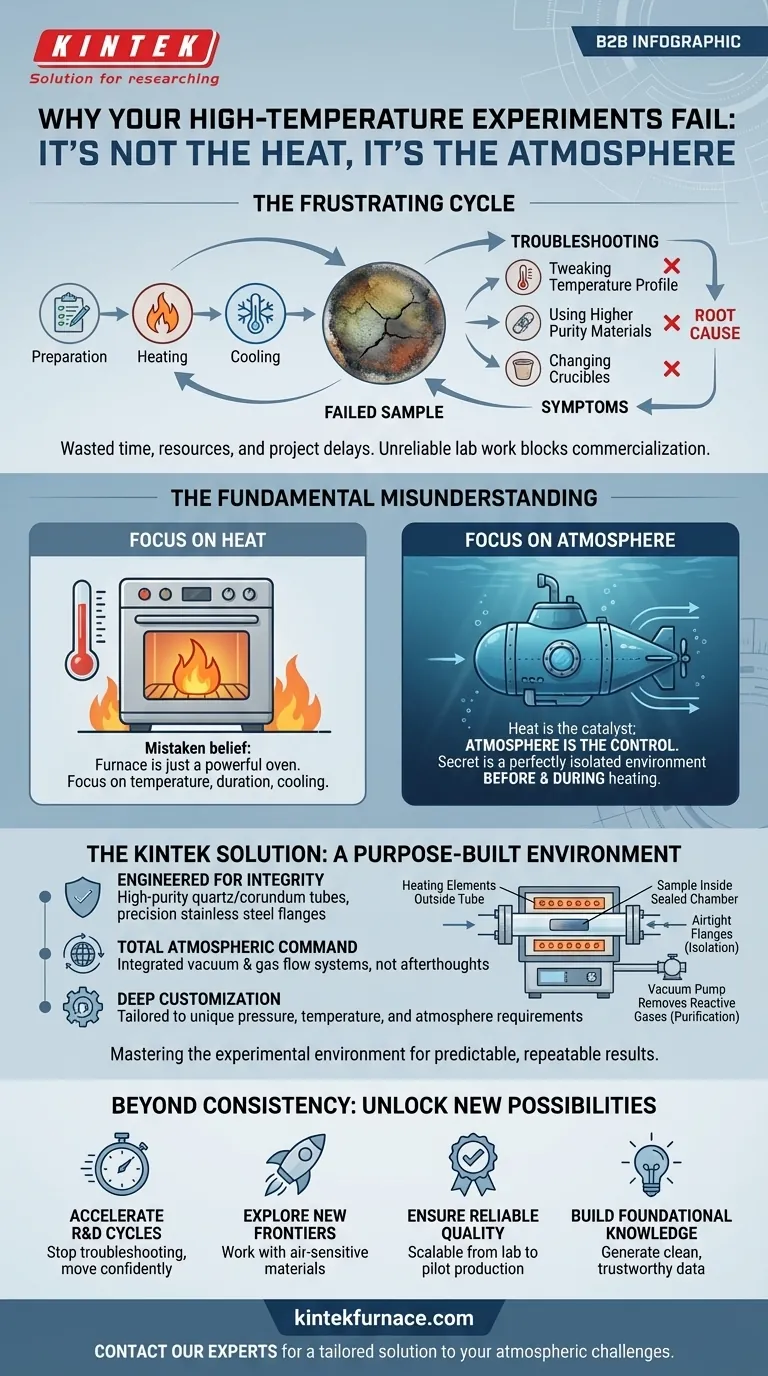

The Frustrating Cycle of Failed Experiments

If this scenario feels familiar, you are not alone. Across countless advanced material labs, researchers and engineers find themselves trapped in a frustrating loop. They face inconsistent results, unexplained sample contamination, and failed synthesis runs.

In response, the typical troubleshooting process begins:

- "Maybe the temperature profile is wrong." So you spend days tweaking ramp rates and hold times.

- "Perhaps the starting material wasn't pure enough." You invest in more expensive, higher-purity precursors.

- "Let's try a different crucible." Another variable is changed in the hope of a different outcome.

While logical, these steps often lead to the same disappointing result. That’s because they are attempts to fix the symptoms, not the underlying disease. The business consequences are severe: project timelines stretch from weeks into months, R&D budgets are consumed by repeated tests, and the path to commercializing a new material becomes blocked by unreliable and unrepeatable lab work.

The Fundamental Misunderstanding: Why We Blame the Wrong Culprit

The core problem lies in a common misconception. We tend to think of a high-temperature furnace as simply a very powerful, precise oven. We focus all our attention on the heat—the temperature, the duration, the cooling rate. But for most advanced material processes, heat is merely the catalyst; the atmosphere is the control.

The real secret to a successful high-temperature process isn't just achieving a high temperature, but creating a perfectly isolated, controlled environment for the sample before and during heating.

Think of it like a deep-sea submersible. The mission isn't just about reaching a certain depth (the temperature). The mission's success depends entirely on the integrity of the hull (the sealed tube) and the life support system inside (the atmosphere control). If the internal environment is compromised, the mission fails, no matter how deep you go.

This is precisely how a vacuum tube furnace is designed to work. The heating elements are outside the tube. The sample is inside a sealed chamber. The most critical steps happen before the temperature even begins to rise:

- Isolation: The tube is sealed airtight by high-integrity flanges.

- Purification: A vacuum pump removes reactive gases like oxygen and moisture that would otherwise ruin your sample at high temperatures.

- Control: A specific, pure gas (like argon or nitrogen) can be introduced to create the exact inert or reactive atmosphere your process requires.

The common solutions fail because they ignore this principle. No amount of temperature tweaking can compensate for a microscopic leak or residual oxygen that contaminates your sample the moment it gets hot.

The KINTEK Solution: A Purpose-Built Environment for Your Materials

To solve this problem at its root, you don't need just a hotter box; you need a superior isolation chamber. You need a system engineered from the ground up with the principle of absolute atmospheric control at its core.

This is the philosophy behind KINTEK’s advanced vacuum tube furnaces. We understand that predictable, repeatable results come from mastering the experimental environment.

- Engineered for Integrity: Our systems utilize high-purity quartz or corundum tubes paired with precision-machined stainless steel flanges to create a reliably sealed chamber, experiment after experiment.

- Total Atmospheric Command: The integrated vacuum and gas flow systems are not afterthoughts; they are central to the furnace’s design, giving you the power to create the exact vacuum level or gas environment your material demands.

- Deep Customization: We recognize that no two research projects are identical. A standard, off-the-shelf furnace might get you 90% of the way there, but that last 10%—the part that causes the failures—is where customization matters. Our in-house manufacturing and R&D expertise allow us to tailor a furnace solution to the unique pressure, temperature, and atmospheric requirements of your specific process.

Our furnaces aren't just tools that get hot; they are precision instruments designed to give you unwavering control over the universe inside the tube.

Beyond Consistency: The New Possibilities You Unlock

When you move past the struggle of just trying to get a successful run, you unlock a new level of innovation. With a furnace that delivers a perfectly controlled environment every time, you can:

- Accelerate R&D Cycles: Stop wasting time on troubleshooting and failed experiments. Move confidently from one successful test to the next, dramatically shortening your development timeline.

- Explore New Frontiers: Work with highly sensitive, air-reactive materials that were previously too challenging, opening up new avenues for discovery.

- Ensure Reliable Quality: Transition your lab-scale process to pilot production with confidence, knowing that the results you achieved in research are repeatable and scalable.

- Build Foundational Knowledge: Generate clean, reliable data that you can trust, allowing you to build a true understanding of your material's behavior without the noise of environmental contamination.

Your material innovation should not be held hostage by the limitations of your equipment. If inconsistent results, contamination, or process variability are stalling your progress, the issue might not be your science—it's your environment. Let's discuss how to build the precise, controlled environment your project demands to succeed.

Contact Our Experts to share the challenges of your unique application and discover a tailored solution.

Visual Guide

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

Related Articles

- Beyond the Checklist: Why Your High-Temperature Furnace Fails (And How to Ensure It Won't)

- The Invisible Contaminant: Why Your Furnace Atmosphere is Sabotaging Your Results

- Why Your High-Temperature Furnace Fails: It’s Not the Heating Element, It’s the Physics

- Beyond the Alarm: The Hidden Safety Risks in Your High-Temperature Furnace

- Why Your High-Temperature Experiments Fail: It’s Not Bad Luck, It’s Your Furnace