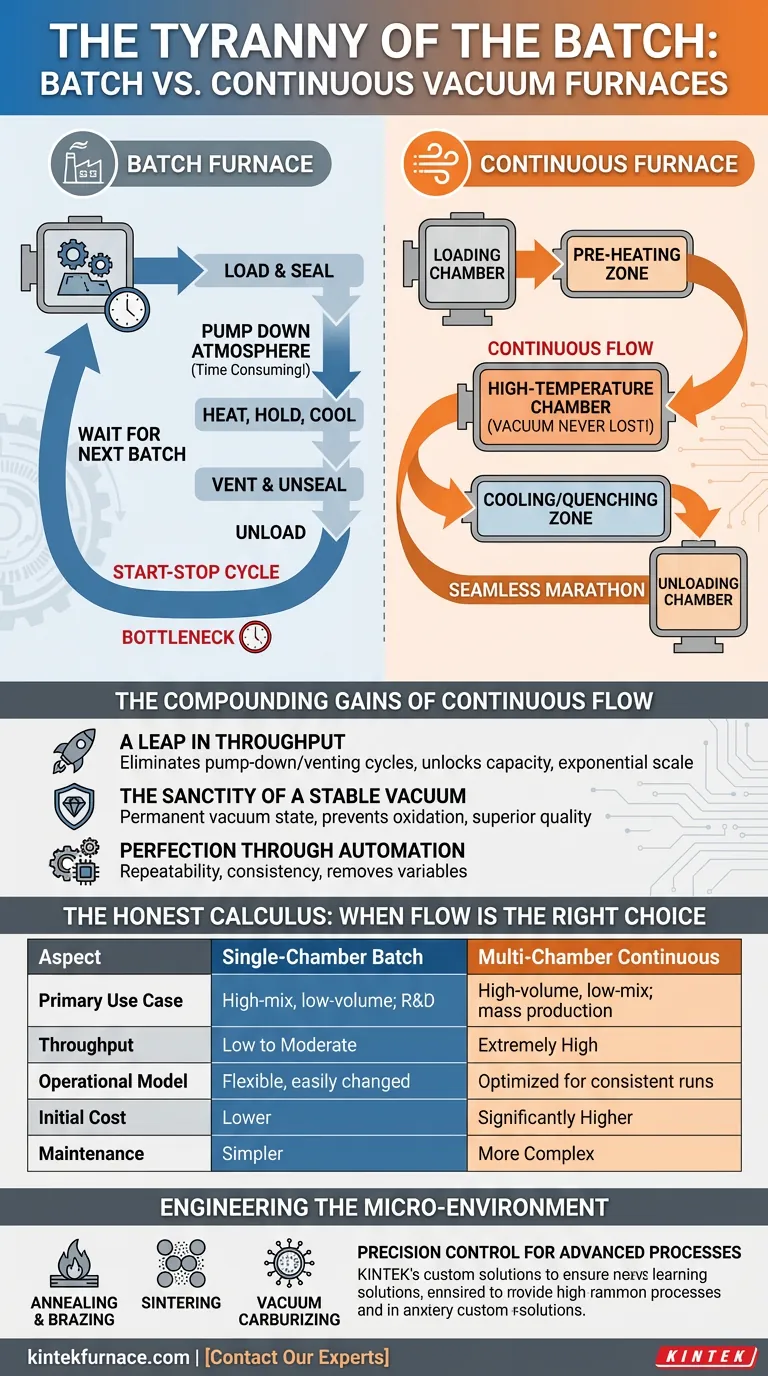

Picture a workshop floor. In the corner sits a large, single-chamber vacuum furnace, the workhorse of the operation. The process is a familiar, almost meditative rhythm: load the parts, seal the door, pump down the atmosphere. Heat, hold, cool. Vent, unseal, unload.

And then, wait. The entire multi-hour cycle must begin again for the next batch.

This is the tyranny of the batch. It's a reliable process, but it's fundamentally a start-and-stop existence. Every cycle is an island, disconnected from the last, creating a bottleneck that dictates the pace of the entire production line. This isn't just a mechanical limitation; it's a psychological one, forcing a mindset of segmented work rather than continuous flow.

Beyond the Bottleneck: The Continuous Flow Philosophy

The core inefficiency of batch production isn't the thermal process itself, but the time spent preparing the environment. Pumping down to a vacuum and venting back to atmosphere for every single load is where productive time is lost.

A multi-chamber continuous vacuum furnace is the elegant engineering answer to this problem. It doesn't just improve the old process; it introduces a new philosophy.

Instead of a single chamber doing everything, the furnace is a series of specialized zones connected by vacuum-sealed passages:

- Loading Chamber: Parts enter the system.

- Pre-heating Zone: Parts are gradually brought to temperature.

- High-Temperature Chamber: The core thermal process (brazing, sintering, etc.) occurs.

- Cooling/Quenching Zone: Parts are cooled under controlled conditions.

- Unloading Chamber: Finished parts exit the system.

Parts move automatically from one chamber to the next. The crucial insight is this: the central high-temperature chamber never loses its vacuum. It remains a pristine, stable environment, ready for a continuous stream of material. This transforms the workflow from a series of disjointed sprints into a seamless marathon.

The Compounding Gains of Uninterrupted Work

Breaking free from the batch cycle creates compounding benefits that go far beyond just speed.

A Leap in Throughput

By eliminating the pump-down/venting cycle for the main chamber, the furnace’s capacity is unlocked. The only limiting factor becomes the thermal process time itself, not the setup. This allows for a dramatic increase in production scale, turning a linear process into an exponential one.

The Sanctity of a Stable Vacuum

In a batch furnace, the pristine vacuum environment is temporary—created and destroyed with every cycle. In a continuous furnace, the vacuum is a permanent, protected state. This stability is critical for achieving superior material quality. It completely prevents oxidation and contamination from atmospheric gases, ensuring the absolute integrity of the materials being processed.

Perfection Through Automation and Repetition

Computer-controlled systems manage the transfer of parts and the parameters of each chamber. Every component experiences the exact same thermal profile, from pre-heating to cooling. This level of automation guarantees a degree of repeatability and consistency that is nearly impossible to achieve in manually managed batch systems. It removes variables and builds confidence in the final product.

Engineering the Micro-Environment

The true beauty of these systems lies in the precision they offer. Because each chamber is dedicated to a single task, it can be optimized to an extraordinary degree.

This enables advanced processes with pinpoint control:

- Annealing & Brazing: Creating perfect bonds and material properties.

- Sintering: Forging powdered metals into solid, high-performance parts.

- Vacuum Carburizing: Hardening surfaces with exceptional uniformity.

Furthermore, features like partial pressure control allow engineers to fine-tune the atmosphere, preventing specific metallurgical effects like the vaporization of chromium from steel at high temperatures. Achieving this requires deep expertise, which is why purpose-built systems are essential. At KINTEK, our philosophy is that the furnace must be tailored to the process, which is why we specialize in customizing vacuum systems for unique material science challenges.

The Honest Calculus: When Flow is the Right Choice

A continuous furnace is a powerful tool, but it's a specialist. The decision to adopt one is a strategic choice between scale and flexibility.

| Aspect | Single-Chamber Batch Furnace | Multi-Chamber Continuous Furnace |

|---|---|---|

| Primary Use Case | High-mix, low-volume; R&D | High-volume, low-mix; mass production |

| Throughput | Low to Moderate | Extremely High |

| Operational Model | Flexible, easily changed parameters | Optimized for consistent, repeated runs |

| Initial Cost | Lower | Significantly Higher |

| Maintenance | Simpler | More Complex, requires skilled staff |

The calculus is clear. If your operation thrives on producing large quantities of a consistent part, the continuous furnace offers an unmatched return on investment by driving down per-unit costs and maximizing output. If your work involves frequent changes in part size, material, or thermal cycles, a flexible, high-quality batch furnace may be the more practical solution.

Ultimately, moving to a continuous system is an inflection point. It is a commitment to industrial-scale production, where efficiency, quality, and repeatability are paramount. The choice isn't just about hardware; it's about defining the future of your manufacturing capability. Whether you are scaling up with a continuous system or optimizing a specialized batch process, having a partner who understands the nuances of furnace design is critical.

At KINTEK, our R&D and manufacturing expertise covers the full spectrum, from Muffle and Tube furnaces to highly customized Vacuum and CVD systems, ensuring your equipment is a perfect match for your ambition. If you're ready to move beyond existing limitations and engineer a more efficient future, Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

Related Articles

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection

- Gravity as an Ally: The Counterintuitive Genius of Vertical Vacuum Furnaces

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- Mastering the Void: How Custom Vacuum Furnaces Forge the Future of Materials