The Illusion of a Simple Joint

We tend to focus on what we can see. In a complex assembly—be it a satellite waveguide or a medical implant—our attention goes to the visible seam, the fillet of the brazed joint. We test its strength, we inspect its integrity.

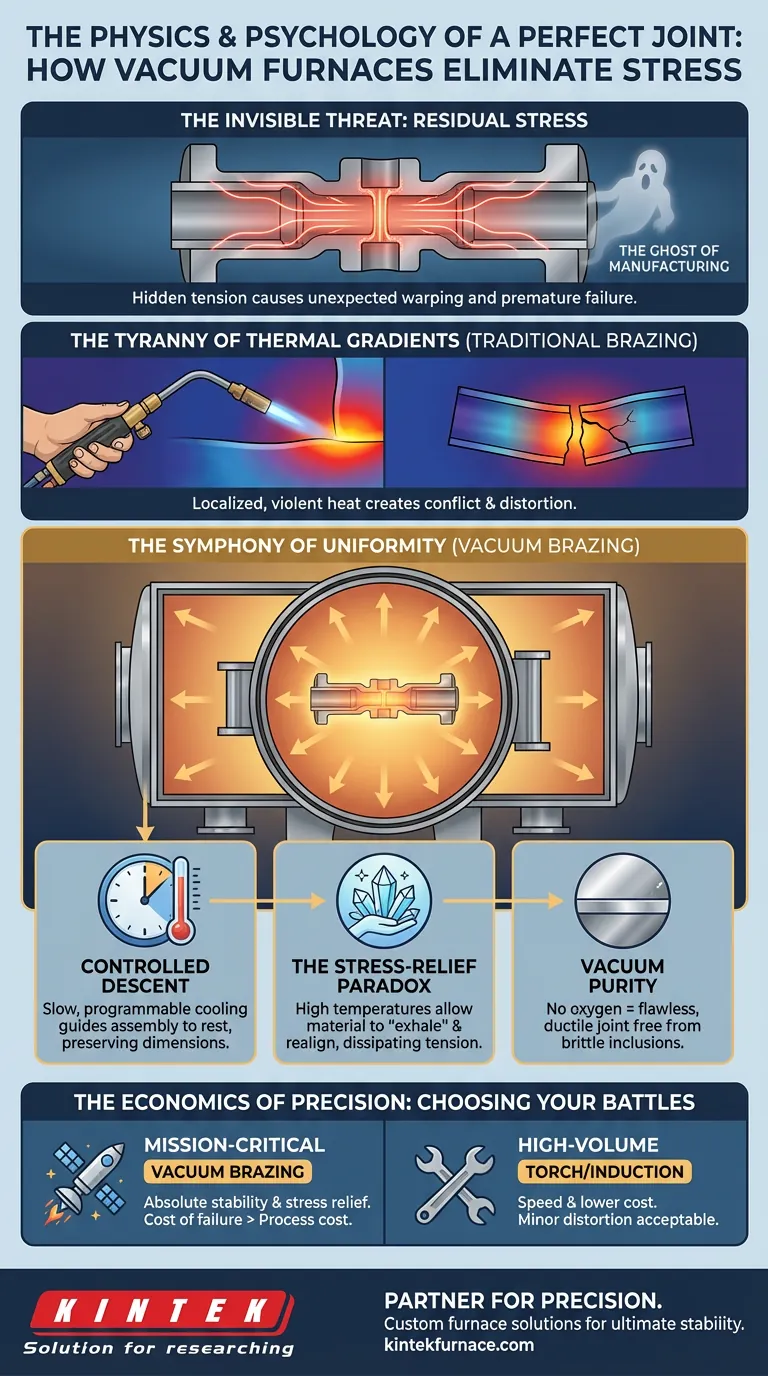

But the most significant threat to a component's long-term reliability is often invisible: the locked-in residual stress hidden within the material. This internal tension, a ghost of the manufacturing process, is what causes unexpected warping, dimensional instability, and premature failure.

Vacuum brazing is not merely a method for joining parts. It is a holistic thermal strategy designed to conquer this unseen enemy.

The Tyranny of the Thermal Gradient

The fundamental cause of material stress is uneven change. When one part of an assembly heats or cools faster than another, a microscopic tug-of-war begins. The hotter section wants to expand, while the cooler section resists. This conflict creates permanent internal stress and distortion.

The Symphony of Uniform Heating

Traditional joining methods, like torch brazing, are a localized, often violent, application of heat. It's fast, but it creates intense thermal gradients.

A vacuum furnace operates on a completely different philosophy. It creates an immersive thermal bath. Radiant heat envelops the entire assembly from all directions, ensuring every flange, wall, and crevice heats up at the same slow, uniform rate. The component expands as a single, harmonious unit, eliminating the internal conflict that leads to warping.

Achieving this level of uniformity isn't accidental; it's the result of precise engineering within the furnace itself. Advanced systems, like the highly customizable vacuum furnaces from KINTEK, are designed specifically to create and maintain these pristine thermal environments.

The Art of a Controlled Descent

The journey back to room temperature is just as critical. A rapid, uncontrolled cool-down is the single biggest culprit for locking in residual stress.

Vacuum brazing allows for a programmable, precisely controlled cooling ramp. This slow, deliberate descent ensures that thick sections and thin sections contract in unison. It's less like quenching a fire and more like guiding the assembly gently back to a state of rest, preserving its exact dimensions.

The Paradox: Brazing to Relieve Stress

Here lies the most profound benefit of the process. You place components into the furnace to join them, but they emerge in a more relaxed, stable state than when they went in.

The vacuum brazing cycle is, in effect, a simultaneous stress-relief heat treatment.

By holding the assembly at the brazing temperature (often 800°C to 1150°C), the process allows the crystalline structure of the base metals to realign. Internal stresses from prior machining, bending, or welding are given the energy and time to dissipate. The material essentially "exhales," releasing the tension it carried.

The Purity of a Vacuum

The "vacuum" in vacuum brazing does more than just prevent heat loss. It creates an environment of absolute purity, which plays a crucial role in preventing stress.

Eliminating the Seeds of Fracture

In the presence of air, heated metal forms brittle oxides on its surface. When brazing filler flows over an oxidized surface, it creates a weak bond filled with microscopic inclusions. These impurities act as stress concentration points—the starting lines for future cracks.

A vacuum environment eliminates oxygen. The filler metal flows onto a perfectly clean, virgin surface, creating a flawless, ductile joint free from the seeds of its own destruction. This metallurgical integrity is fundamental to a component that can be trusted under load.

Choosing Your Battles: The Economics of Precision

No engineering solution is universal. The meticulous control of vacuum brazing comes at the cost of time and complexity. A cycle can last for hours, making it more expensive than faster alternatives.

The choice depends entirely on the psychology of your application's requirements: What is the cost of failure?

| Application Profile | Recommended Process | Rationale |

|---|---|---|

| Mission-Critical, Complex Geometry | Vacuum Brazing | Demands absolute dimensional stability and stress relief. |

| (Aerospace, Medical, High-Performance) | The cost of failure vastly outweighs the process cost. | |

| High-Volume, Simple Parts | Torch / Induction Brazing | Speed and lower cost are the primary drivers. |

| (General Hardware, Non-Critical) | A minor degree of distortion or stress is acceptable. |

For those in the first category, precision isn't a luxury; it's a prerequisite. This is where partnering with experts in thermal systems becomes critical. Companies like KINTEK provide not just the furnace, but the deep R&D and customization capability to tailor a thermal process to the unique demands of your materials and designs.

Engineering Certainty

Ultimately, vacuum brazing is a strategy for removing uncertainty. It replaces the variables of a manual process with the programmable certainty of a controlled environment. It tackles both the visible joint and the invisible stress, delivering a final assembly that is not only strong but dimensionally predictable and internally stable.

For applications where failure is not an option, achieving this level of thermal control requires equipment built with the same philosophy of precision. If your work demands the ultimate in material stability and joint integrity, let's discuss how a custom-engineered vacuum furnace can become the cornerstone of your process. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

Related Articles

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

- Beyond the Bond: The Physics and Psychology of Vacuum Furnace Brazing

- Beyond the Void: The Hidden Costs of a Perfect Vacuum Furnace

- The Unseen Enemy: Why Vacuum Furnaces Are a Bet on Perfection