The Weakest Point is Never Just a Point

Imagine a turbine blade inside a jet engine. It spins thousands of times per minute, enduring temperatures that would melt steel and forces that could tear it apart. Its structural integrity is not a suggestion; it's a physical law that keeps a plane in the sky.

Now, imagine that blade is an assembly of multiple, complex parts. The weakest link is no longer the raw material, but the seam that joins them.

In high-stakes engineering—from aerospace to medical implants—we have a psychological obsession with eliminating variables. We fear the microscopic flaw, the invisible contamination, the hidden stress that could initiate a catastrophic failure. This is why the most critical joining processes happen not in the open air, but in a near-perfect vacuum.

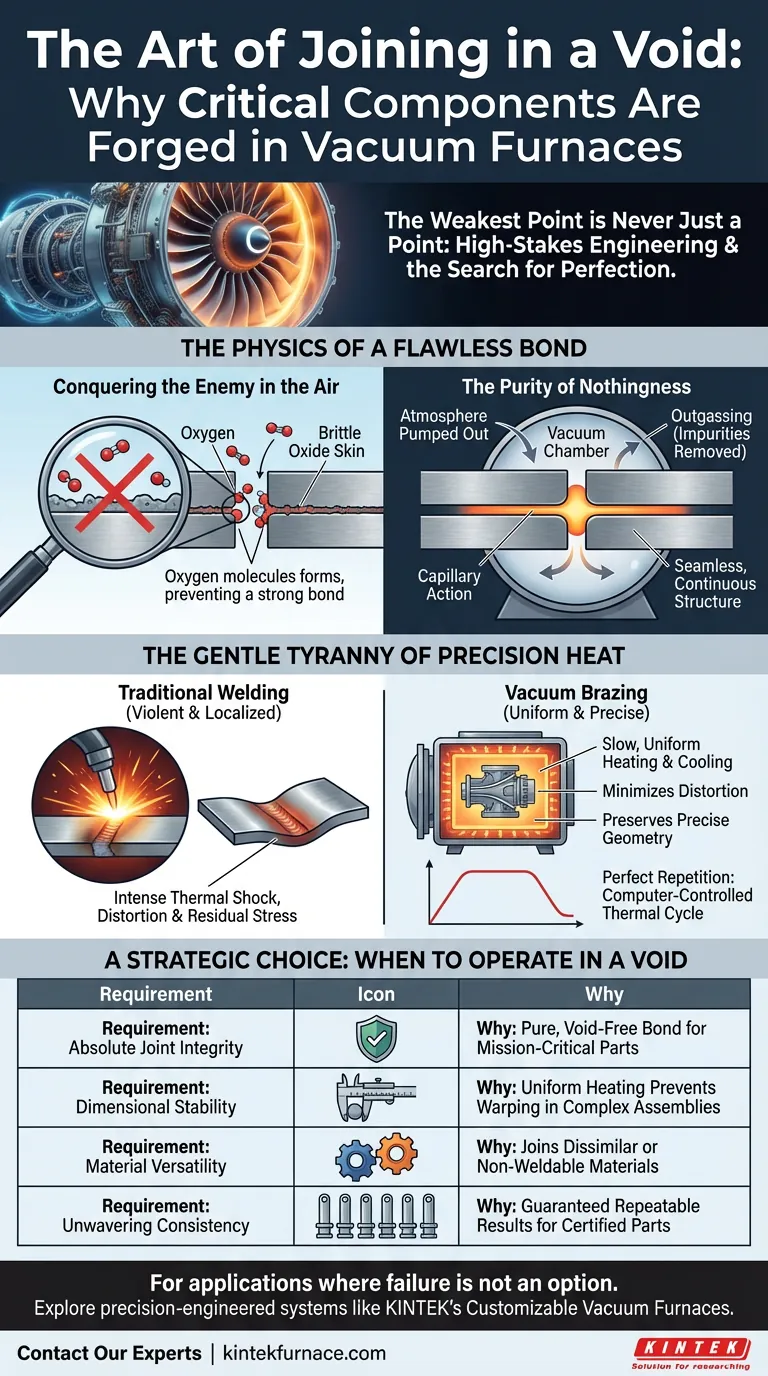

The Physics of a Flawless Bond

The magic of vacuum brazing isn't just about heat; it's about the profound impact of nothingness. By removing the atmosphere, we fundamentally alter the rules of metallurgy.

Conquering the Enemy in the Air

When heated, metal in the open air instantly reacts with oxygen, forming a brittle, invisible skin of oxides. This layer acts like a barrier, preventing the brazing alloy from creating a true, seamless metallurgical bond. The resulting joint is compromised from the start.

A vacuum furnace removes this threat. By pumping the atmosphere down to a near-perfect void, metal surfaces remain atomically clean. When the filler metal melts, it flows via capillary action into the joint, bonding directly with the parent materials. The result is not two pieces stuck together, but a single, continuous new structure.

The Purity of Nothingness

The vacuum does more than just prevent contamination from getting in. It actively pulls impurities out.

As the components heat up, the vacuum environment encourages outgassing—a process where trapped gases and volatile contaminants within the metal itself are drawn out. This purifies the joint from the inside, eliminating voids that could become stress concentrators and future points of failure. For a surgical implant, this level of purity is non-negotiable.

The Gentle Tyranny of Precision Heat

The second pillar of this process is not the vacuum itself, but the absolute control over thermal energy.

Escaping the Trauma of Localized Heat

Traditional welding is a violent, localized event. It introduces intense thermal shock, creating massive temperature gradients that warp, twist, and build residual stress into the component. For parts with tolerances measured in microns, this is unacceptable.

Vacuum brazing is the opposite. The entire assembly is heated slowly and uniformly within the furnace chamber. This gentle, encompassing heat minimizes distortion, preserving the precise geometry of even the most intricate assemblies.

The Power of Perfect Repetition

This entire thermal cycle—from ramp-up to soak to cool-down—is governed by a computer. This ensures that every part in a batch, and every batch that follows, undergoes the exact same process. This is the foundation of quality control in industries where consistency is synonymous with safety.

Achieving this requires more than just a recipe; it demands a furnace engineered for absolute precision. The ability to hold a specific vacuum level while executing a complex thermal profile is where the design of the equipment itself becomes critical. Expertly engineered systems, like KINTEK's customizable vacuum furnaces, are built specifically to manage these variables, providing the stable and repeatable environment where perfect bonds are forged.

A Strategic Choice, Not a Universal Solution

Vacuum brazing is a discipline of specialization. It is not the fastest or the cheapest method of joining metals.

- Investment: Vacuum furnaces are significant pieces of capital equipment.

- Time: The process is inherently slow, involving pump-down, heating, and cooling cycles that can take hours.

- Expertise: It requires a deep understanding of metallurgy, vacuum physics, and thermal engineering.

This is not a process for joining simple brackets. It is a strategic capability reserved for applications where the cost of failure is immeasurably high.

When to Operate in a Void

The decision is driven by the consequence of failure.

| Requirement | Why Vacuum Brazing is the Answer |

|---|---|

| Absolute Joint Integrity | The vacuum ensures a pure, void-free bond for mission-critical parts. |

| Dimensional Stability | Uniform heating prevents warping in complex or thin-walled components. |

| Material Versatility | It allows the joining of dissimilar or non-weldable materials. |

| Unwavering Consistency | Computer control guarantees repeatable results essential for certified parts. |

For applications where failure is not an option, the void is not empty—it is full of potential. To explore how precision-engineered vacuum systems can achieve this for your most critical components, Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

Related Articles

- Mastering the Void: How Custom Vacuum Furnaces Forge the Future of Materials

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection