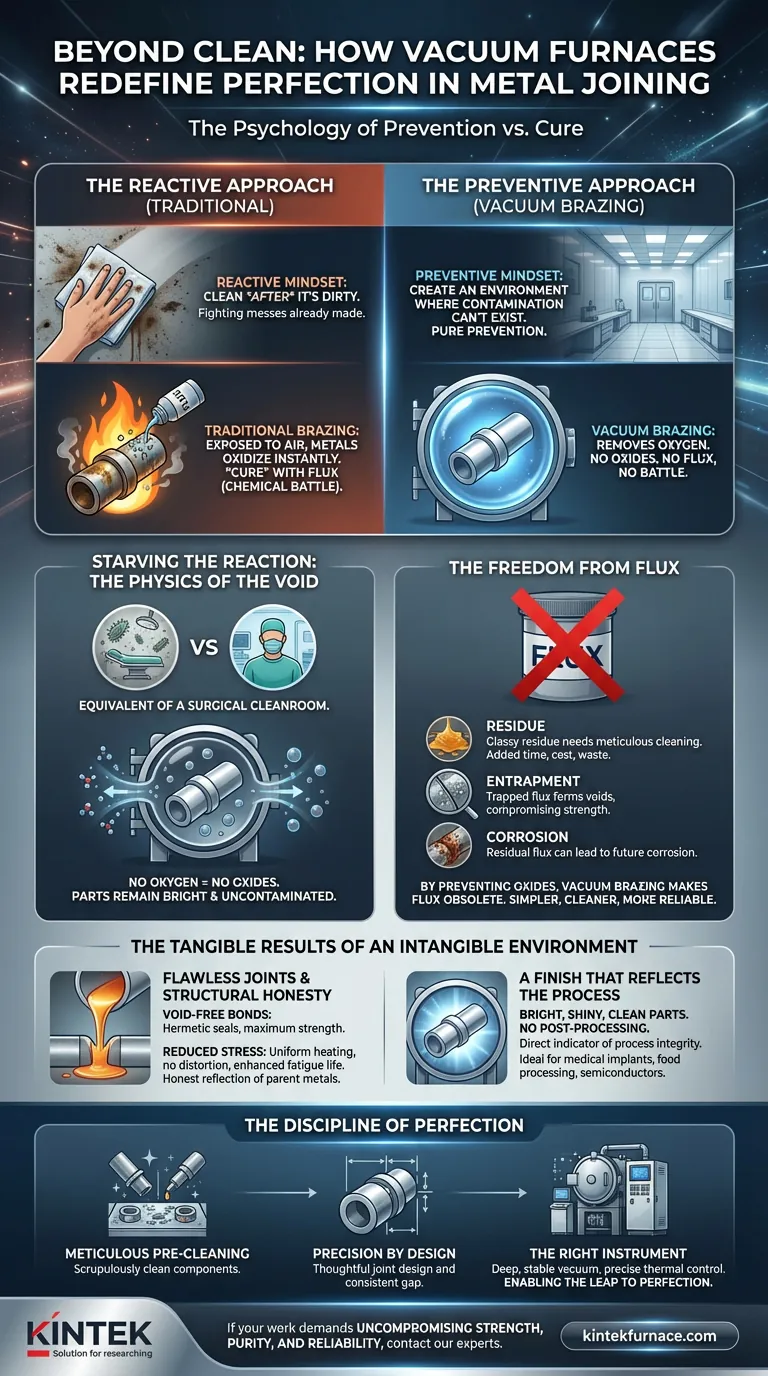

The Psychology of Prevention vs. Cure

In our daily lives, we are conditioned to clean things after they get dirty. We wipe a spill, wash a dish, or scrub a surface. Our mindset is reactive. We fight against messes that have already been made.

But in precision engineering, this reactive approach is a compromise. The residue of the fight—the cleaning agent, the microscopic damage—can become a future point of failure.

At the high temperatures required for brazing metals, this problem is magnified. Exposed to air, hot metal surfaces instantly tarnish, forming a layer of oxides that acts as a wall, preventing a perfect bond. The conventional solution is to apply a chemical flux to aggressively dissolve this wall as it forms. This is the "cure."

Vacuum brazing offers a more elegant philosophy. It doesn't fight the contamination. It creates an environment where contamination can't exist. It is pure prevention.

Starving the Reaction: The Physics of the Void

Imagine a surgeon trying to operate in a dusty room. They can continuously sterilize their instruments, but the environment itself is the source of the problem. This is akin to brazing in open air with flux.

A vacuum furnace is the equivalent of a surgical cleanroom.

By removing the atmosphere, we remove the key reactant: oxygen. In the pristine, near-perfect void of a high-vacuum furnace, there are simply not enough oxygen molecules to form oxides, even at temperatures exceeding 1100°C.

The metal parts remain bright and uncontaminated throughout the heating cycle. There is no wall to break down, no chemical battle to be waged. The process disarms the problem at its source.

The Freedom from Flux

Flux is the necessary evil of conventional brazing. It's a powerful chemical agent designed to scour oxides from the joint. But it comes with a cost.

- Residue: Flux leaves behind a glassy residue that must be meticulously cleaned, adding time, cost, and a potential source of environmental waste.

- Entrapment: Tiny amounts of flux can become trapped within the brazed joint, creating voids that compromise its strength and integrity.

- Corrosion: If not perfectly cleaned, residual flux can lead to corrosion long after the part has been put into service.

By preventing oxides from forming, vacuum brazing makes flux entirely obsolete. This single step eliminates an entire class of potential defects and post-processing headaches. The process becomes simpler, cleaner, and more reliable.

The Tangible Results of an Intangible Environment

The purity of the vacuum environment translates directly into the physical quality of the finished part. The benefits are not just aesthetic; they are fundamental to performance.

Flawless Joints and Structural Honesty

With no oxides or flux to obstruct its path, the molten filler metal flows smoothly and completely into the joint, guided purely by the physics of capillary action. This results in:

- Void-Free Bonds: Maximizing joint strength and creating hermetic seals critical for vacuum and high-pressure applications.

- Reduced Stress: The uniform heating and controlled cooling inside a furnace minimize residual stress, preventing distortion and enhancing the part's fatigue life.

The final joint is an honest reflection of the parent metals' properties, uncompromised by chemical interference.

A Finish That Reflects the Process

Parts that emerge from a vacuum furnace are bright, shiny, and metallically clean. They often require no post-processing, ready for immediate integration into the next stage of assembly. This isn't just a cosmetic benefit; it's a direct indicator of the process's integrity.

This level of cleanliness makes vacuum brazing the default choice for industries where purity is paramount, such as medical implants, food processing equipment, and semiconductor manufacturing components.

The Discipline of Perfection

This elegant outcome does not happen by accident. It demands a disciplined approach. The vacuum furnace maintains cleanliness; it does not create it.

- Meticulous Pre-Cleaning: Any oils, greases, or surface contaminants on the parts will vaporize in the vacuum and contaminate the entire system. The process begins with scrupulously clean components.

- Precision by Design: The process relies on a precise, consistent gap between the parts to draw the filler metal in. This requires thoughtful joint design and manufacturing.

- The Right Instrument: Achieving and maintaining a deep, stable vacuum at extreme temperatures is a formidable engineering challenge. Success is impossible without a furnace capable of precise, repeatable control over the entire thermal cycle.

This is where the equipment becomes an extension of the philosophy. A high-performance vacuum furnace isn't just a tool; it's the environment where perfection is made possible. At KINTEK, we specialize in creating these controlled environments. Our advanced vacuum furnace systems are engineered to provide the stability, control, and deep vacuum levels required for the most demanding applications. We build the instruments that enable this leap from reactive cleaning to preventative perfection.

If your work demands joints with uncompromising strength, purity, and reliability, the solution lies in controlling the environment itself. Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

Related Articles

- The Architecture of Purity: Deconstructing the Vacuum Furnace System

- The Most Important Number in a Vacuum Furnace Isn't Its Temperature

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- In Pursuit of Purity: The Silent Power of the Vacuum Furnace

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection