Understanding the core features of a rotary furnace is essential for any engineer or professional responsible for material processing. These features are not arbitrary design choices; they are the mechanisms that directly govern process efficiency, thermal uniformity, and final product quality. A firm grasp of how they work is the foundation for optimizing or specifying a system for a given application.

The true value of a rotary furnace lies in its dynamic nature. Its unique combination of rotation and tilt provides unparalleled control over heat distribution and material mixing, making it a cornerstone for high-throughput, continuous processing where product consistency is non-negotiable.

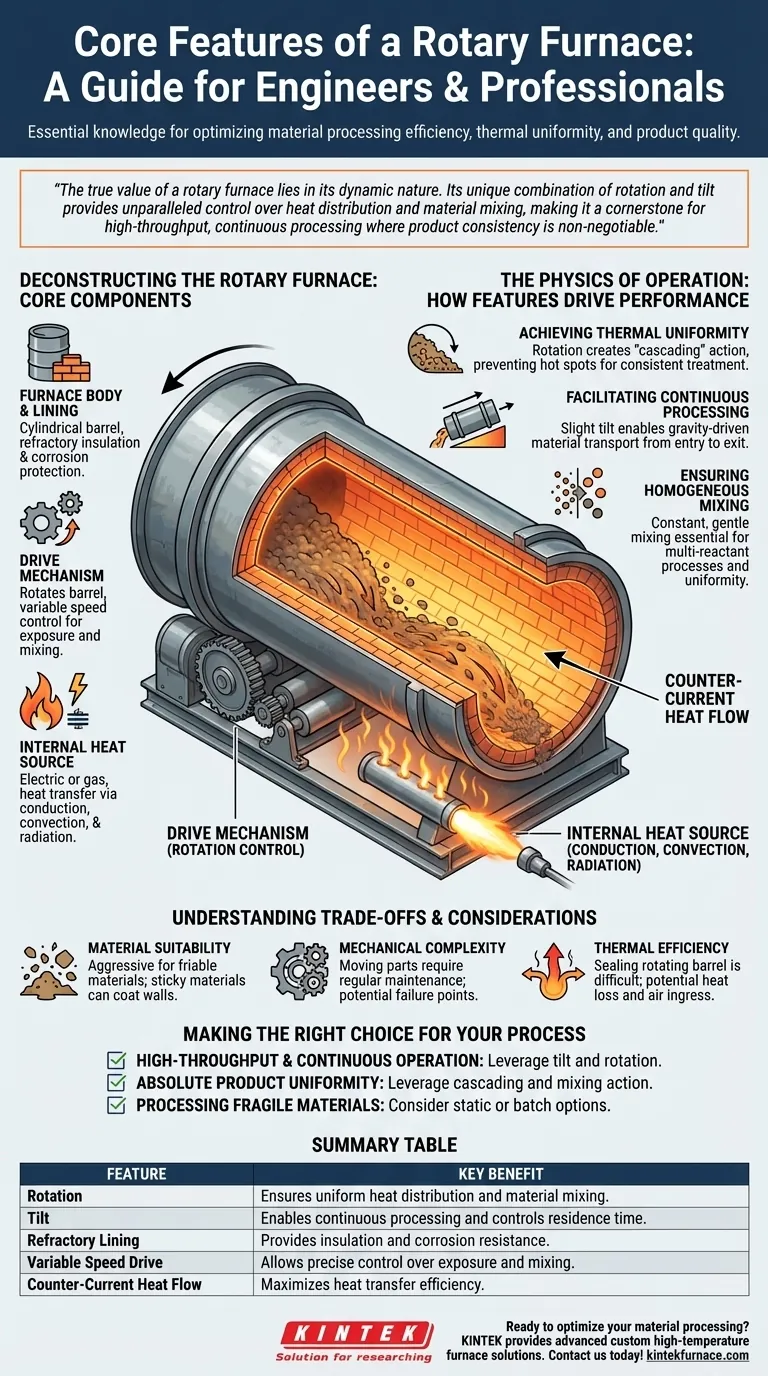

Deconstructing the Rotary Furnace: Core Components

To understand its function, you must first understand its anatomy. A rotary furnace is a system of integrated parts, each serving a critical purpose.

The Furnace Body and Lining

The main structure is a cylindrical barrel, or drum, often constructed from welded steel plate. This body can range from small lab-scale tubes to massive industrial drums over 200 meters long.

Inside this body is a refractory lining. This layer, made of specialized bricks or castable cement, serves two functions: insulating the steel shell from extreme internal temperatures and protecting it from chemical corrosion by the process materials.

The Drive Mechanism

The furnace is mounted on rollers or a drive gear that rotates the entire barrel around its longitudinal axis. This rotation is the furnace's defining feature.

Crucially, this rotation is often managed by a variable speed drive. Adjusting the rotational speed gives engineers direct control over how long the material is exposed to heat and the degree of mixing it experiences.

The Internal Heat Source

Heat is generated either by electric elements or gas burners. This energy is transferred to the material through a combination of conduction (direct contact with hot walls), convection (hot gases passing through the chamber), and radiation (from the hot lining and heat source).

Typically, hot gases flow in a counter-current direction—opposite to the flow of the material—to maximize heat transfer efficiency.

The Physics of Operation: How Features Drive Performance

The components work in concert to create a unique processing environment. The interplay between the furnace's rotation and its physical orientation dictates its primary benefits.

Achieving Thermal Uniformity

As the furnace rotates, the bed of material is continuously lifted and tumbled. This action, known as cascading, constantly exposes new surfaces to the heat source.

This prevents the formation of hot spots and ensures every particle receives a near-identical thermal treatment. The result is exceptional thermal uniformity and a highly consistent final product.

Facilitating Continuous Processing

Rotary furnaces are mounted at a slight tilt or angle. As the barrel rotates, gravity gently pulls the material from the higher entry point down toward the lower exit point.

This simple mechanism transforms a batch process into a continuous operation. Material is fed in one end and discharged at the other, enabling high-throughput production with minimal manual intervention. The degree of tilt, along with rotational speed, controls the material's residence time in the furnace.

Ensuring Homogeneous Mixing

The tumbling motion inherent to the furnace's rotation provides constant, gentle mixing. This is critical for processes involving multiple solid reactants or when uniformity is paramount, such as in calcination or mineral roasting.

Understanding the Trade-offs and Considerations

While powerful, a rotary furnace is not a universal solution. Its unique mechanics introduce specific limitations.

Material Suitability

The tumbling action can be too aggressive for friable or delicate materials, which may break down into unwanted fines. Likewise, materials that are sticky or prone to melting can coat the furnace walls, reducing efficiency and creating maintenance challenges.

Mechanical Complexity

The rotating seals, drive gear, and support rollers are moving parts that require regular maintenance. Compared to a static or batch furnace, a rotary furnace has more potential points of mechanical failure.

Thermal Efficiency

Sealing a rotating barrel is inherently more difficult than sealing a static chamber. This can lead to heat loss and potential air ingress, which may require careful atmosphere control and can impact overall energy efficiency.

Making the Right Choice for Your Process

Ultimately, selecting the right furnace technology depends entirely on your primary process goals.

- If your primary focus is high-throughput and continuous operation: The automated material transport enabled by the furnace's tilt and rotation is your key advantage.

- If your primary focus is absolute product uniformity: The cascading and mixing action driven by rotation is the feature you must leverage to achieve thermal and chemical homogeneity.

- If your primary focus is processing fragile materials or liquids: A static hearth or batch oven that avoids mechanical tumbling is likely a more suitable choice.

Matching the fundamental features of the furnace to your specific material and process requirements is the key to a successful and efficient operation.

Summary Table:

| Feature | Key Benefit |

|---|---|

| Rotation | Ensures uniform heat distribution and material mixing |

| Tilt | Enables continuous processing and controls residence time |

| Refractory Lining | Provides insulation and corrosion resistance |

| Variable Speed Drive | Allows precise control over exposure and mixing |

| Counter-Current Heat Flow | Maximizes heat transfer efficiency |

Ready to optimize your material processing with a custom rotary furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production requirements. Contact us today to discuss how our tailored solutions can enhance your efficiency and product quality!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- In what environments are rotary tube furnaces considered indispensable? Essential for Uniform Thermal Processing

- How do rotary tube furnaces enhance efficiency in materials processing? Boost Throughput and Quality

- How is the Rotary Tube Tilt Furnace used in the carbon activation process? Achieve Uniform, High-Porosity Activated Carbon

- What optional features enhance the processing capabilities of rotary tube furnaces? Boost Efficiency with Advanced Customizations

- What level of process control do rotary tube furnaces provide? Achieve Precise Thermal Processing for Uniform Results