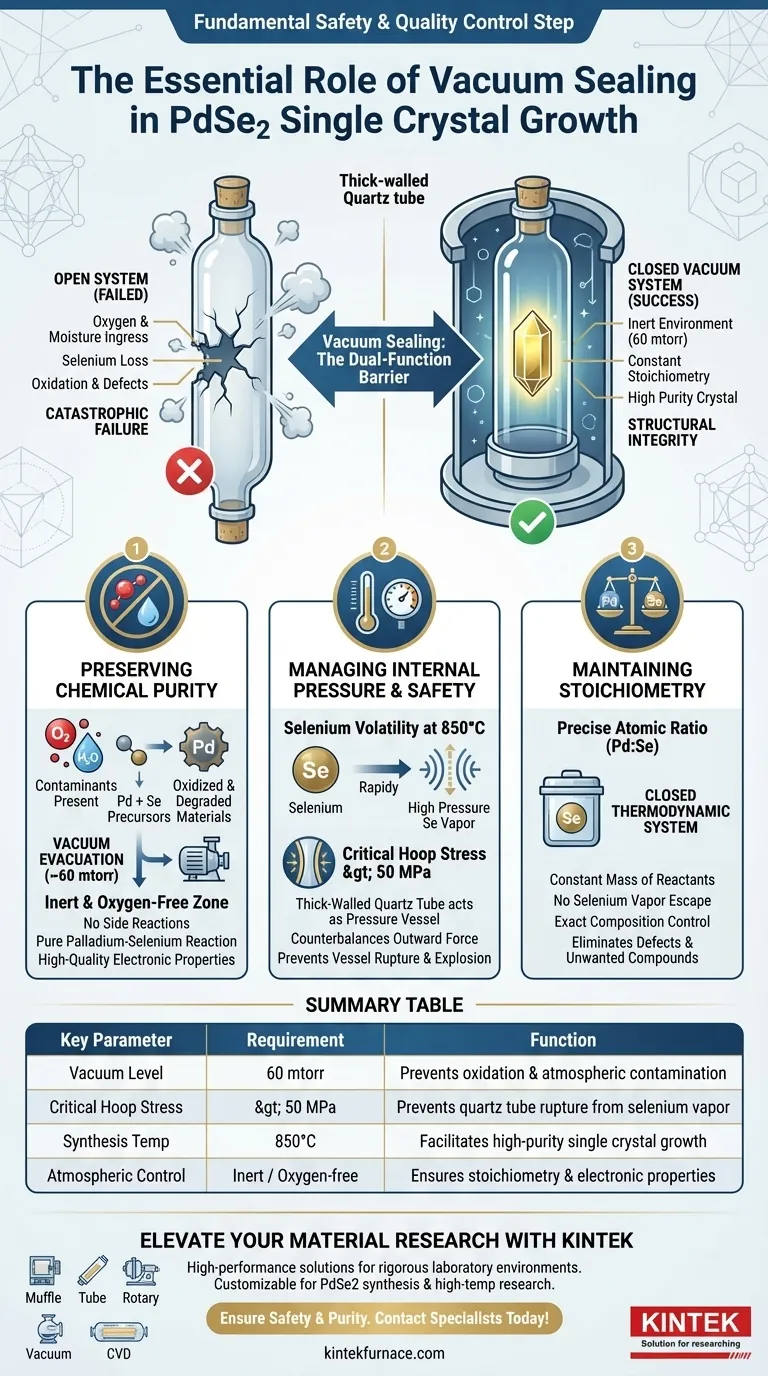

Vacuum sealing is the fundamental safety and quality control step in the synthesis of Palladium Diselenide (PdSe2) single crystals. It establishes a precise environment—specifically around 60 mtorr—that prevents the high-temperature oxidation of raw materials and fortifies the quartz vessel to withstand the immense internal pressure generated by selenium volatilization at 850°C.

By eliminating reactive atmospheric gases, vacuum sealing ensures the chemical purity of the crystal while simultaneously transforming the quartz tube into a high-strength pressure vessel. This dual function is the only way to maintain the correct atomic ratio (stoichiometry) without causing a catastrophic mechanical failure of the container.

Preserving Chemical Purity

Creating an Inert Environment

The primary objective of vacuum sealing is to create an oxygen-free zone. At the synthesis temperature of 850°C, raw materials are highly reactive.

Even trace amounts of oxygen or water vapor can lead to the immediate oxidation of the precursors. Evacuating the tube to approximately 60 mtorr removes these contaminants, ensuring the reaction remains purely between Palladium and Selenium.

Preventing Side Reactions

Without a high-quality seal, atmospheric gases interact with the melt. This degrades the raw materials before the crystal lattice can form.

Vacuum sealing isolates the growth environment completely. This guarantees that impurities do not incorporate into the crystal structure, which is vital for achieving high-quality electronic properties in the final PdSe2 sample.

Managing Internal Pressure and Safety

The Volatility of Selenium

Selenium (Se) has a high vapor pressure. When heated to synthesis temperatures, it volatilizes, transitioning rapidly from solid to gas.

This phase change creates significant internal pressure within the quartz tube. If the tube is not properly sealed or structurally sound, this pressure can rupture the vessel.

Structural Integrity and Hoop Stress

The vacuum sealing process is not just about air removal; it is about preparing the tube to act as a pressure vessel. The thick-walled quartz tubes must possess a critical hoop stress exceeding 50 MPa.

This mechanical strength is required to counterbalance the outward force of the selenium vapor. The vacuum seal ensures the tube is closed while the glass is pliable, creating a unified barrier that maintains containment throughout the heating cycle.

Maintaining Stoichiometry

Locking in the Ratio

Single crystal growth requires an exact atomic ratio, known as stoichiometry. For PdSe2, you need precise amounts of Palladium and Selenium to react.

If the tube leaks or breaks due to pressure, Selenium vapor escapes. This loss shifts the ratio of reactants, leading to defects or the formation of entirely different, unwanted compounds.

The "Closed System" Principle

Vacuum sealing creates a closed thermodynamic system. Because nothing enters or leaves, the mass of the reactants remains constant.

This ensures that the initial weigh-in of materials directly correlates to the final crystal composition. It allows the chemistry to proceed exactly as calculated without variable losses to the atmosphere.

Understanding the Operational Risks

The Danger of Tube Failure

The most significant risk in this process is a physical explosion. If the quartz tube wall is too thin or the seal is imperfect, the hoop stress generated by the selenium vapor will exceed the quartz's tensile strength.

This compromises safety and destroys the experiment. The relationship between the vacuum level, tube wall thickness, and temperature ramp rate must be carefully calculated.

Consequences of Poor Vacuum

Achieving a vacuum of 60 mtorr is a specific threshold. If the vacuum is insufficient (pressure is too high), trapped pockets of air will expand upon heating.

This adds additive pressure to the selenium vapor, increasing the likelihood of rupture. Furthermore, the remaining oxygen will chemically attack the surface of the forming crystal, ruining its purity.

Making the Right Choice for Your Goal

To ensure a successful PdSe2 growth run, prioritize your setup based on these critical parameters:

- If your primary focus is Safety: Ensure you are using thick-walled quartz tubes capable of withstanding a critical hoop stress > 50 MPa to handle the expansion of selenium gas.

- If your primary focus is Crystal Purity: Verify your vacuum system can reliably achieve and hold 60 mtorr to fully eliminate oxygen and moisture before sealing.

Ultimately, the vacuum seal is the invisible structural component that holds the entire high-temperature chemical reaction together.

Summary Table:

| Key Parameter | Requirement | Function |

|---|---|---|

| Vacuum Level | 60 mtorr | Prevents oxidation and atmospheric contamination |

| Critical Hoop Stress | > 50 MPa | Prevents quartz tube rupture from selenium vapor |

| Synthesis Temp | 850°C | Facilitates high-purity single crystal growth |

| Atmospheric Control | Inert / Oxygen-free | Ensures stoichiometry and electronic properties |

Elevate Your Material Research with KINTEK

Precise single crystal growth requires equipment that can handle extreme pressures and vacuum thresholds. KINTEK provides high-performance solutions designed for rigorous laboratory environments. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your unique PdSe2 synthesis or high-temp research needs.

Ensure safety and purity in every experiment. Contact our specialists today to find your custom furnace solution!

Visual Guide

References

- Y. Zhang, Chun Ning Lau. Quantum octets in high mobility pentagonal two-dimensional PdSe2. DOI: 10.1038/s41467-024-44972-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why are laboratory furnaces considered essential in industrial and scientific applications? Unlock Precision and Control for Your Materials

- How does a high-precision heating stage contribute to the drying and crystallization of FAPbBr3 nanosheets?

- Why is the use of high-purity alumina crucibles essential for the synthesis of Ni3In2Se2? | Precision Material Purity

- What additional convenience feature is included with the water circulating vacuum pump? Discover Easy Mobility and More

- What is the primary function of the alumina crucible set in the synthesis of Eu5.08-xSrxAl3Sb6? Expert Analysis

- How are laboratory furnaces used in material synthesis? Unlock Precise Control for Advanced Materials

- What are the technical considerations for using alumina crucibles? Optimize High-Entropy Alloy Purity & Microstructure

- What are the advantages of using open corundum crucibles for thermal analysis? Accurate Biomass & Coal Data