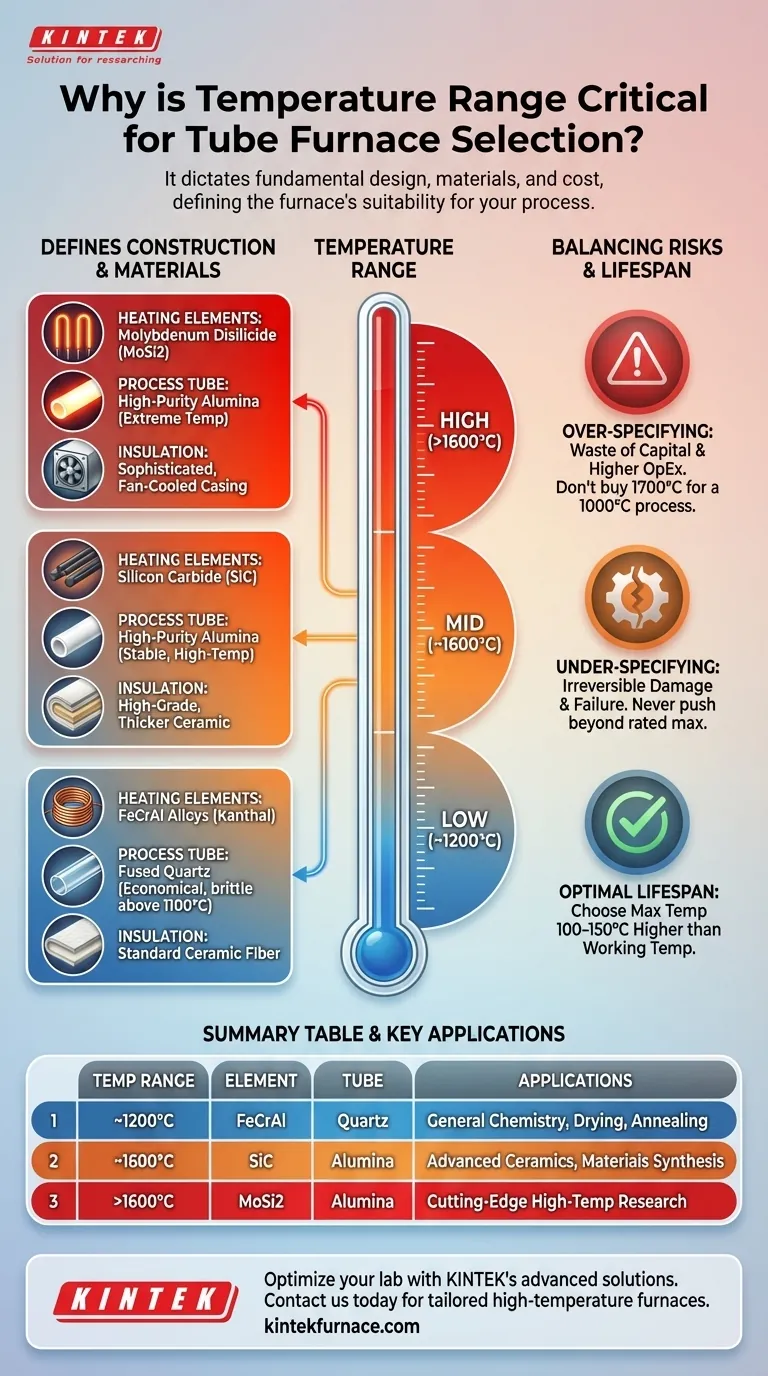

At its core, selecting a tube furnace's temperature range is the single most critical decision because it dictates the instrument's fundamental design, material composition, and overall cost. It is not merely a performance specification; it is the factor that defines the furnace's heating technology, physical construction, and suitability for your specific scientific or industrial processes.

The temperature range you require does not just determine if a furnace can reach your target temperature. It fundamentally defines which heating elements, insulation materials, and process tubes can be used, creating a direct and often exponential relationship between temperature capability and equipment cost.

How Temperature Range Defines Furnace Construction

Choosing a temperature range is less about selecting a number on a dial and more about choosing a specific class of engineering. Each temperature bracket requires fundamentally different materials and design principles to operate safely and reliably.

Heating Element Technology

The heart of the furnace is its heating element, and its material composition is directly tied to its maximum stable operating temperature.

- Up to ~1200°C: Furnaces in this range typically use iron-chromium-aluminum (FeCrAl) alloys, often known by the brand name Kanthal. These are robust and highly cost-effective for a wide range of general-purpose applications.

- Up to ~1600°C: Reaching these higher temperatures requires silicon carbide (SiC) elements. These are more brittle and expensive but offer excellent performance for applications like advanced ceramics processing and annealing.

- Above 1600°C: The highest temperature applications demand molybdenum disilicide (MoSi2) elements. These can operate reliably up to 1700°C or even 1800°C but come at a significant cost premium and have specific operational requirements.

Process Tube Material

The tube that holds your sample must be able to withstand the furnace's heat without degrading or reacting with your material.

- Fused Quartz is an excellent and economical choice for temperatures up to approximately 1100°C. Above this, it begins to soften (devitrify) and can become brittle upon cooling.

- High-Purity Alumina is the standard for high-temperature work, remaining stable in most atmospheres at temperatures of 1600°C or higher.

Insulation and Casing

Higher temperatures generate more thermal stress and require more sophisticated insulation. A 1700°C furnace needs thicker, higher-grade ceramic fiber insulation and a more robust, often double-walled and fan-cooled, steel casing compared to a 1200°C model to ensure operator safety and energy efficiency.

Understanding the Trade-offs

Selecting a temperature range is a balancing act between capability, budget, and longevity. Misjudging your needs can lead to significant and costly consequences.

The Pitfall of Over-Specifying

Purchasing a 1700°C furnace for a process that only requires 1000°C is not "future-proofing"—it's a waste of capital. You are paying a premium for MoSi2 elements and advanced insulation you will never use. These furnaces can also have higher energy consumption and more complex maintenance schedules.

The Risk of Under-Specifying

This is the most critical error. A furnace rated for 1200°C cannot be pushed to 1300°C without causing rapid, irreversible damage to its heating elements and compromising its structural integrity. This not only destroys the equipment but also invalidates any experimental results.

The Impact on Operational Lifespan

Continuously operating any furnace at its absolute maximum rated temperature will drastically shorten its lifespan. For optimal longevity, you should choose a furnace with a maximum temperature approximately 100-150°C higher than your highest required working temperature. This provides a safety margin that protects the heating elements from thermal fatigue.

Making the Right Choice for Your Application

To select the correct furnace, you must align its capabilities with your specific experimental or production goals.

- If your primary focus is on general chemistry, drying, or annealing up to 1100°C: A standard furnace with FeCrAl elements and a quartz process tube is the most cost-effective and reliable choice.

- If your primary focus is on advanced materials synthesis or high-temperature processing (1200-1600°C): You must invest in a furnace with silicon carbide (SiC) elements and use high-purity alumina process tubes.

- If your primary focus is cutting-edge research requiring extreme heat (>1600°C): Your only option is a high-performance furnace with molybdenum disilicide (MoSi2) elements, and you must budget for its significant initial cost and specific operational needs.

Ultimately, an informed decision on temperature range ensures your investment is both effective for today's work and viable for tomorrow's ambitions.

Summary Table:

| Temperature Range | Heating Element | Process Tube Material | Key Applications |

|---|---|---|---|

| Up to ~1200°C | FeCrAl Alloys (e.g., Kanthal) | Fused Quartz | General chemistry, drying, annealing |

| Up to ~1600°C | Silicon Carbide (SiC) | High-Purity Alumina | Advanced ceramics, materials synthesis |

| Above 1600°C | Molybdenum Disilicide (MoSi2) | High-Purity Alumina | Cutting-edge high-temperature research |

Ready to optimize your lab with the right tube furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your research and efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing