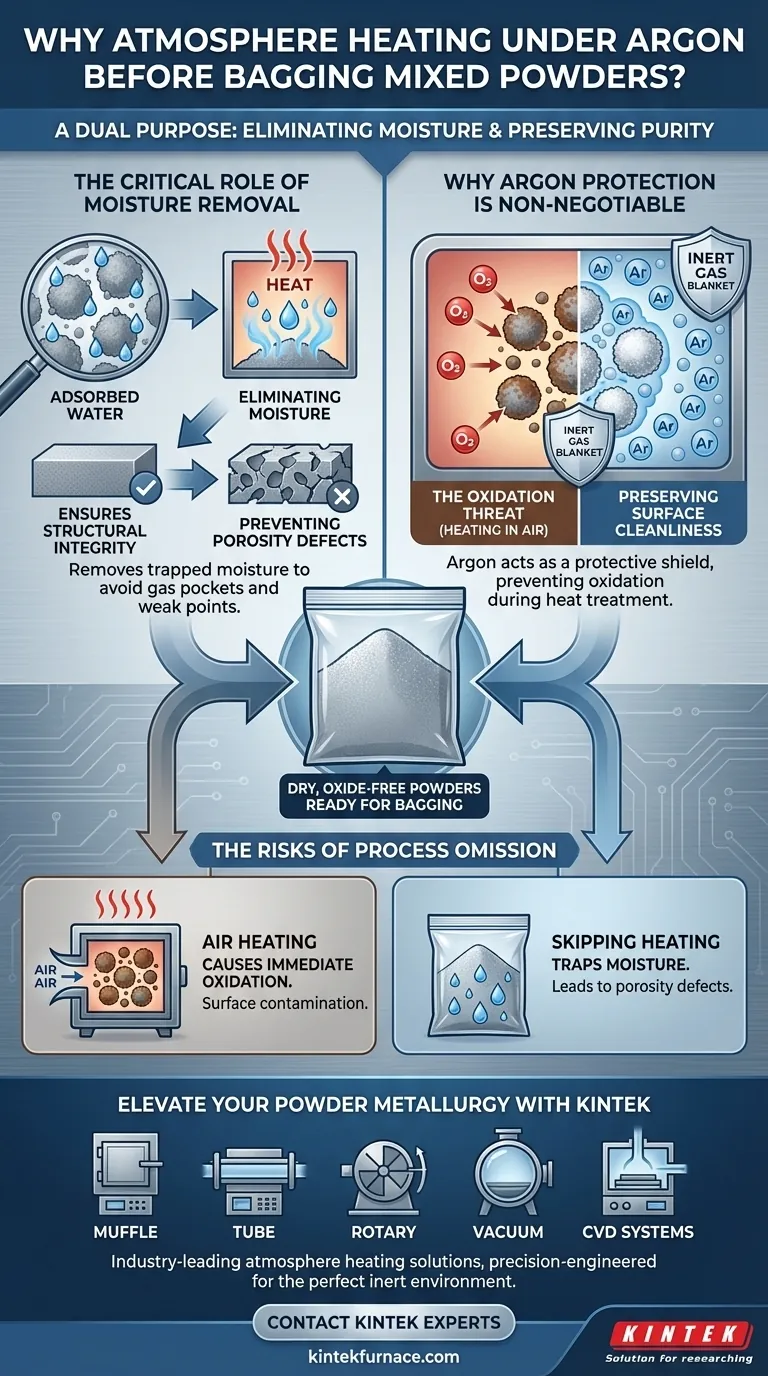

Atmosphere heating under argon serves a dual purpose: eliminating moisture while strictly preserving material purity. By subjecting mixed powders to heat within an inert argon environment, manufacturers effectively strip away adsorbed water molecules without exposing the delicate powder surfaces to oxygen, which would otherwise cause rapid oxidation. This step is critical for ensuring the powder is chemically stable and physically sound before it is sealed in bags.

The primary objective of this process is to eliminate porosity defects caused by moisture contamination. The argon atmosphere acts as a protective shield, allowing the necessary heat treatment to occur without inducing oxidation, thereby ensuring the structural integrity of the final product.

The Critical Role of Moisture Removal

Eliminating Adsorbed Water

Mixed powders naturally attract and hold water molecules on their surface, a phenomenon known as adsorption. Heating the powder is the most effective method to drive off this trapped moisture.

Preventing Porosity Defects

If moisture remains in the powder during subsequent processing, it can vaporize and create gas pockets. These pockets lead to porosity, which are microscopic voids that weaken the final material.

Ensuring Structural Integrity

By removing moisture prior to bagging, you minimize the risk of internal defects. This ensures the final component maintains the expected density and strength.

Why Argon Protection is Non-Negotiable

The Oxidation Threat

Heat accelerates chemical reactions, making powders highly susceptible to oxidation if exposed to air. Using an atmosphere heating equipment creates a controlled environment that excludes oxygen.

The Function of Inert Gas

Argon is an inert gas, meaning it does not react chemically with the metal powders. It creates a "blanket" around the particles during the heating cycle.

Preserving Surface Cleanliness

This protective environment ensures that while moisture is removed, the powder surface remains metallic and clean. A clean surface is essential for proper bonding and performance in later manufacturing stages.

The Risks of Process Omission

The Consequence of Air Heating

Attempting to dry powders in standard air would exchange one problem for another. While the moisture might evaporate, the heat would cause the powder particles to oxidize immediately.

The Cost of Moisture Retention

Skipping the heating step entirely to avoid oxidation leaves moisture trapped in the bag. This residual water serves as a direct contaminant, leading to inevitable porosity defects in the final product.

Making the Right Choice for Your Goal

This process acts as a final quality gate before the material is sealed for storage or transport. To maximize the effectiveness of your powder preparation:

- If your primary focus is Reducing Defects: Prioritize the heating cycle to ensure all adsorbed moisture is fully driven off, eliminating the root cause of porosity.

- If your primary focus is Surface Chemistry: Monitor the argon environment strictly to prevent any trace oxygen from compromising the powder's cleanliness during the heating phase.

Controlled heating under argon is the only way to achieve dry, oxide-free powders ready for high-performance applications.

Summary Table:

| Process Requirement | Purpose & Benefit | Impact of Omission |

|---|---|---|

| Argon Protection | Prevents powder oxidation by creating an inert shield | Powder contamination and surface oxidation |

| Atmosphere Heating | Eliminates adsorbed moisture from powder surfaces | Vaporization leading to gas pockets and porosity |

| Pre-Bagging Step | Ensures long-term chemical and physical stability | Trapped moisture causing internal material defects |

Elevate Your Powder Metallurgy with KINTEK

Don't let moisture or oxidation compromise your material integrity. KINTEK provides industry-leading atmosphere heating solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all precision-engineered to provide the perfect inert environment for your powders. Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique production needs.

Ready to eliminate porosity and guarantee oxide-free results? Contact KINTEK experts today to find the ideal high-temp furnace for your laboratory or production line.

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What role does a high-temperature atmosphere furnace play in Ce3+ doped LCMS ceramics? Unlock Peak Luminescence

- What are some industrial applications of low vacuum atmosphere furnaces? Boost Efficiency in Heat Treatment Processes

- What is the purpose of a chemically reactive atmosphere in material processing? Achieve Precise Surface Modification for Enhanced Performance

- What are the main methods for containing furnace atmospheres? Choose the Best for Your Heat Treatment

- How does atmosphere control ensure Co1-xS@CNT phase purity? Key Steps for High-Purity Synthesis

- Why is a high-precision annealing furnace necessary for optical fibers? Control Nanoparticle Growth for Peak Performance

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are the main application fields of atmosphere furnaces? Essential for Metal, Electronics, and R&D