At their core, low vacuum atmosphere furnaces are used for critical thermal processes like brazing, annealing, sintering, and hardening across a range of industries. They are particularly prevalent in automotive manufacturing for brazing aluminum components, in tool production for hardening steel, and in electronics for joining parts where a controlled, oxygen-free environment is essential.

The central purpose of a low vacuum furnace is not to achieve a perfect vacuum, but to efficiently purge a reactive atmosphere like oxygen and replace it with an inert one. This makes it the ideal, cost-effective solution for processes that require protection from oxidation but do not demand the extreme purity—and expense—of a high vacuum system.

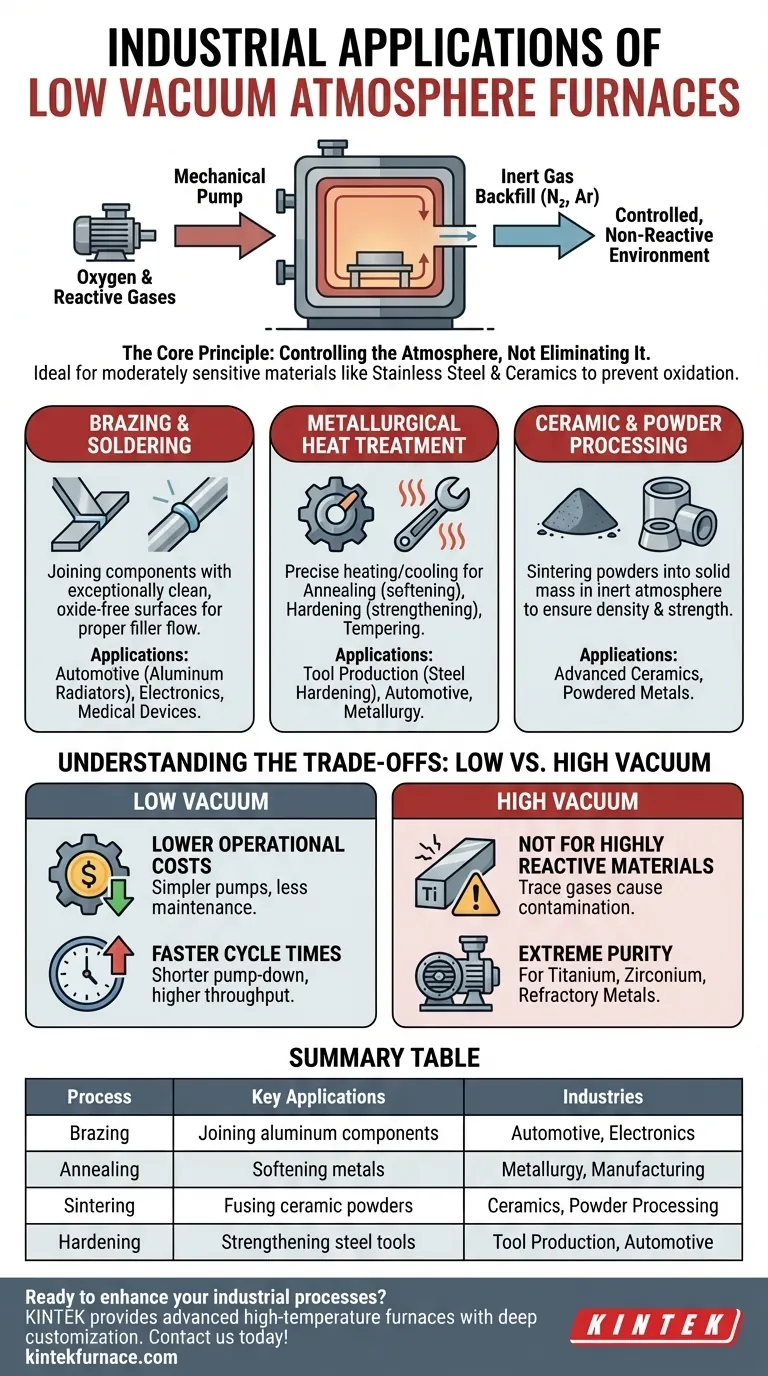

The Core Principle: Why 'Low Vacuum' is the Practical Choice

A low vacuum atmosphere furnace occupies a critical middle ground in thermal processing. Understanding its function reveals why it's a workhorse in so many industrial settings.

Controlling the Atmosphere, Not Eliminating It

The primary goal is atmosphere control. The process involves first using a mechanical pump to achieve a "low" or "rough" vacuum, which effectively removes the majority of the oxygen and other reactive gases from the chamber.

Once this is achieved, the chamber is backfilled with a high-purity inert gas, most commonly nitrogen or argon. This creates a precisely controlled, non-reactive environment for the heat treatment process to occur.

Ideal for Moderately Sensitive Materials

This level of control is perfect for materials that are susceptible to oxidation but are not hyper-reactive. Common metals like stainless steel, various alloys, and many types of ceramics fall into this category.

For these materials, removing the bulk of the oxygen is sufficient to prevent scaling, discoloration, and other unwanted surface reactions, ensuring the final product meets its required mechanical and physical properties.

Key Industrial Processes and Applications

The combination of cost-effectiveness and sufficient atmospheric control makes these furnaces indispensable for several key manufacturing processes.

Metallurgical Heat Treatment

Processes like annealing (softening metal), hardening (increasing strength), and tempering (reducing brittleness) rely on precise heating and cooling cycles.

Performing these in a low vacuum furnace prevents the formation of an oxide layer (scale) on the metal's surface. This results in a cleaner part, eliminates the need for post-processing steps like acid pickling or sandblasting, and ensures uniform material properties.

Brazing and Soldering

Joining components via brazing requires an exceptionally clean, oxide-free surface for the filler metal to properly wet and flow into the joint.

The automotive industry's use for brazing aluminum radiators and heat exchangers is a classic example. The controlled atmosphere prevents the formation of aluminum oxide, which would otherwise inhibit the creation of a strong, leak-proof bond. This is also critical in electronics and medical device manufacturing.

Ceramic and Powder Processing

Sintering is the process of fusing powders together into a solid mass using heat. For many advanced ceramics and powdered metals, performing this in an inert atmosphere is non-negotiable.

Any oxygen present could react with the material, compromising its final density, strength, and structural integrity. A low vacuum furnace provides the necessary protective environment for these materials to consolidate correctly.

Understanding the Trade-offs: Low vs. High Vacuum

Choosing a low vacuum furnace is a strategic decision based on balancing process requirements with operational realities.

Advantage: Lower Operational Costs

Low vacuum systems use simpler, less expensive mechanical pumps and have less stringent sealing requirements than high vacuum systems. This translates directly into lower initial capital investment and reduced ongoing maintenance costs.

Advantage: Faster Cycle Times

Achieving a low vacuum is significantly faster than pumping down to a high vacuum level. This shorter pump-down time means more process cycles can be run in a given period, directly increasing factory throughput and efficiency.

Limitation: Not for Highly Reactive Materials

The primary limitation is that a low vacuum environment still contains trace amounts of residual gases. For highly reactive materials like titanium, zirconium, and certain refractory metals, even these trace amounts can cause embrittlement and contamination.

These sensitive applications demand the extreme purity only achievable with a high vacuum furnace, which uses more advanced pumps (like diffusion or turbomolecular pumps) to remove virtually all atmospheric molecules.

Making the Right Choice for Your Process

Selecting the appropriate furnace technology requires a clear understanding of your material, your process, and your production goals.

- If your primary focus is high-volume, cost-sensitive heat treatment (e.g., steel hardening): A low vacuum atmosphere furnace is the ideal choice for its speed, cost-effectiveness, and sufficient process control.

- If your primary focus is joining non-ferrous components (e.g., aluminum brazing): The clean, inert environment provided by a low vacuum furnace is essential for creating strong, oxide-free bonds.

- If your primary focus is processing highly reactive or exotic materials (e.g., titanium): A high vacuum furnace is non-negotiable to prevent material contamination and ensure final part integrity.

Ultimately, a low vacuum atmosphere furnace is the pragmatic and powerful tool for the vast majority of industrial heat treatment tasks.

Summary Table:

| Process | Key Applications | Industries |

|---|---|---|

| Brazing | Joining aluminum components | Automotive, Electronics |

| Annealing | Softening metals | Metallurgy, Manufacturing |

| Sintering | Fusing ceramic powders | Ceramics, Powder Processing |

| Hardening | Strengthening steel tools | Tool Production, Automotive |

Ready to enhance your industrial processes with reliable, cost-effective furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, boosting efficiency and quality in applications such as brazing, annealing, and sintering. Contact us today to discuss how we can support your production goals!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy