At the core of modern material treatment, the efficiency of a vacuum furnace is not determined by a single component but by a synergistic integration of key technologies. The most significant enhancements come from advanced computer control systems for process automation, innovative thermal management like multi-chamber designs and regenerative cooling, and hardware optimizations such as variable frequency drives (VFDs). These features work together to improve energy consumption, process speed, and product quality.

True furnace efficiency extends beyond simply reducing energy costs. It is a measure of process repeatability, cycle time, and output quality, all of which are achieved by intelligently combining precise digital control with sophisticated mechanical and thermal engineering.

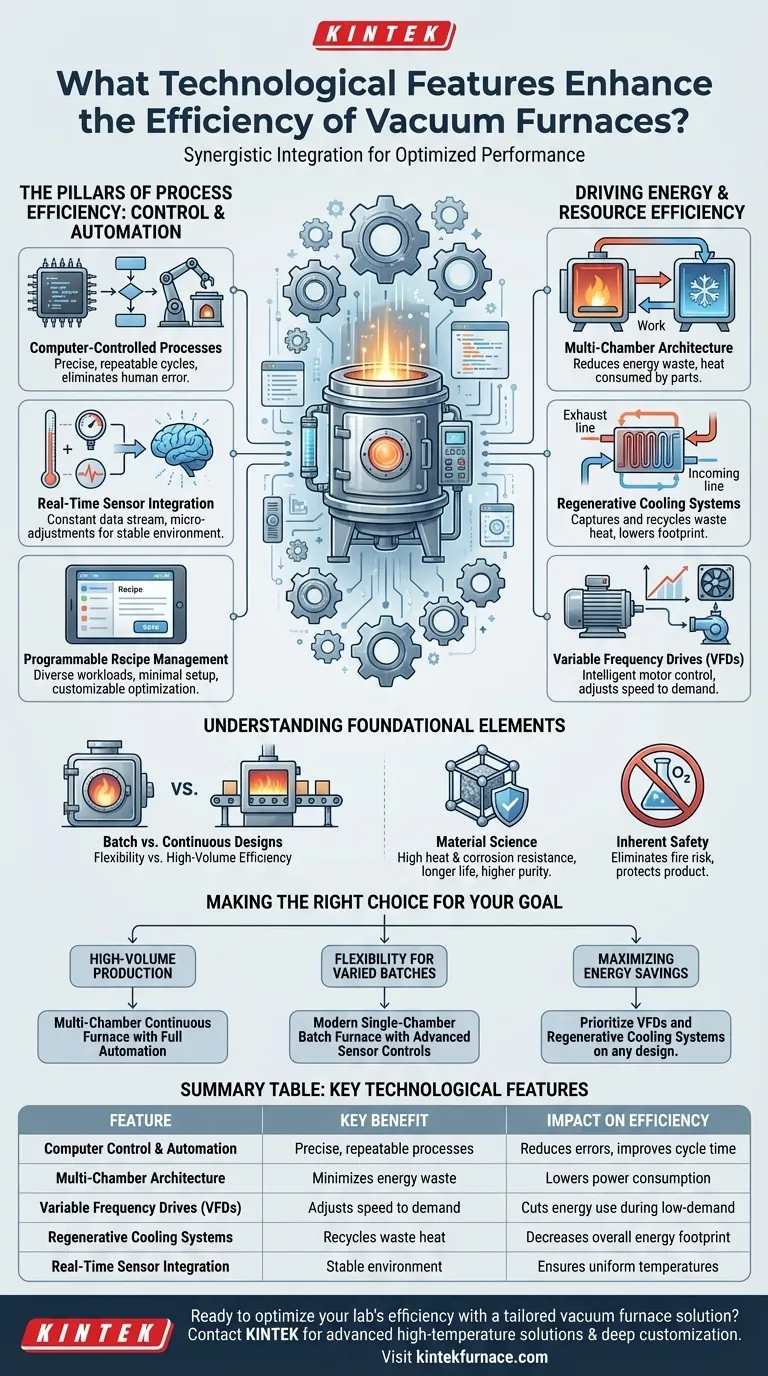

The Pillars of Process Efficiency: Control and Automation

The single greatest leap in furnace efficiency has been the move from manual oversight to fully automated process control. This ensures every cycle is precise and repeatable.

Computer-Controlled Processes

Modern vacuum furnaces operate on electromechanical integration, where software dictates the entire treatment cycle. Operators load pre-programmed recipes tailored to specific materials and part geometries, eliminating manual adjustments and human error.

This level of control allows for extreme precision, ensuring that temperature, vacuum levels, and gas flow adhere to the exact parameters required for a perfect outcome, every time.

Real-Time Sensor Integration

Automation is only as good as the data it receives. Furnaces are embedded with a suite of sensors, including thermocouples for temperature, pressure transducers, and gas flow meters.

These sensors provide a constant stream of real-time data to the central controller, which can then make micro-adjustments to maintain a perfectly stable environment. This is critical for achieving uniform temperatures, which can range from 800°C to over 3,000°C.

Programmable Recipe Management

The ability to program, save, and recall unique recipes is a cornerstone of operational efficiency. It allows for a single furnace to handle diverse workloads with minimal setup time.

Features like programmable cooling rates and the ability to vary gas type and pressure give engineers a high degree of customization to optimize the metallurgical properties of the final product.

Driving Energy and Resource Efficiency

Beyond process control, specific hardware and design choices directly target the reduction of energy and resource consumption.

Multi-Chamber Architecture

In traditional single-chamber batch furnaces, the entire chamber must be heated and cooled for each load. Multiple-chamber designs dramatically reduce this waste.

By moving the workpiece between separate heating and cooling chambers, the heat is consumed almost exclusively by the parts themselves. This minimizes the power required to reheat the hot zone for the next cycle and leads to more consistent electrical load management.

Regenerative Cooling Systems

A significant amount of energy is lost as heat during the cooling phase. Regenerative systems capture this waste heat, often from exhaust gases or cooling water, and recycle it.

This recycled energy can be used to pre-heat incoming gas or other processes, directly reducing the furnace's overall energy footprint.

Variable Frequency Drives (VFDs)

Vacuum pumps and cooling fans are major consumers of electricity. VFDs are intelligent motor controllers that adjust the speed of these components to match the real-time needs of the process.

Instead of running at 100% power continuously, a pump with a VFD will ramp up or down as needed, drastically cutting energy consumption during less demanding phases of the cycle.

Understanding the Trade-offs and Foundational Elements

While advanced features are critical, efficiency also depends on the furnace's fundamental design and the context in which it operates.

Batch vs. Continuous Designs

The majority of vacuum furnaces are batch furnaces, where a stationary load undergoes a complete, pre-programmed cycle. This design offers immense flexibility for unique or varied parts.

Continuous furnaces, often featuring multiple chambers, are designed for high-volume production of uniform parts. They offer superior energy efficiency for mass production but lack the flexibility of batch systems.

The Importance of Material Science

The longevity and reliability of a furnace are forms of long-term efficiency. Furnaces built with materials offering high heat and corrosion resistance have a longer service life and require less maintenance.

This construction also ensures minimal product contamination, as the internal components do not degrade or release by-products into the vacuum environment, leading to higher-purity results.

The Inherent Safety of a Vacuum

An often-overlooked efficiency is safety. By operating in a vacuum, the absence of oxygen eliminates the risk of fire or rapid oxidation that can occur in atmosphere furnaces. This creates a safer environment for operators and protects the product from damage.

Making the Right Choice for Your Goal

Selecting a furnace requires aligning its technological features with your specific operational needs.

- If your primary focus is high-volume, uniform production: A multi-chamber continuous furnace with fully integrated automation will deliver the highest throughput and energy efficiency.

- If your primary focus is flexibility for varied, smaller batches: A modern single-chamber batch furnace equipped with advanced sensor controls and recipe management offers the best process control.

- If your primary focus is maximizing energy savings: Prioritize features like VFDs on pumps and fans and a regenerative cooling system, as these can be applied to both batch and continuous designs.

Understanding these key technologies empowers you to look beyond the initial price and invest in a system that delivers true efficiency for years to come.

Summary Table:

| Feature | Key Benefit | Impact on Efficiency |

|---|---|---|

| Computer Control & Automation | Precise, repeatable processes | Reduces errors, improves cycle time and quality |

| Multi-Chamber Architecture | Minimizes energy waste | Lowers power consumption and heating/cooling times |

| Variable Frequency Drives (VFDs) | Adjusts pump/fan speed to demand | Cuts energy use during low-demand phases |

| Regenerative Cooling Systems | Recycles waste heat | Decreases overall energy footprint |

| Real-Time Sensor Integration | Stable environment maintenance | Ensures uniform temperatures and high purity |

Ready to optimize your lab's efficiency with a tailored vacuum furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, and more. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing process repeatability, energy savings, and product quality. Contact us today to discuss how we can support your specific goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability