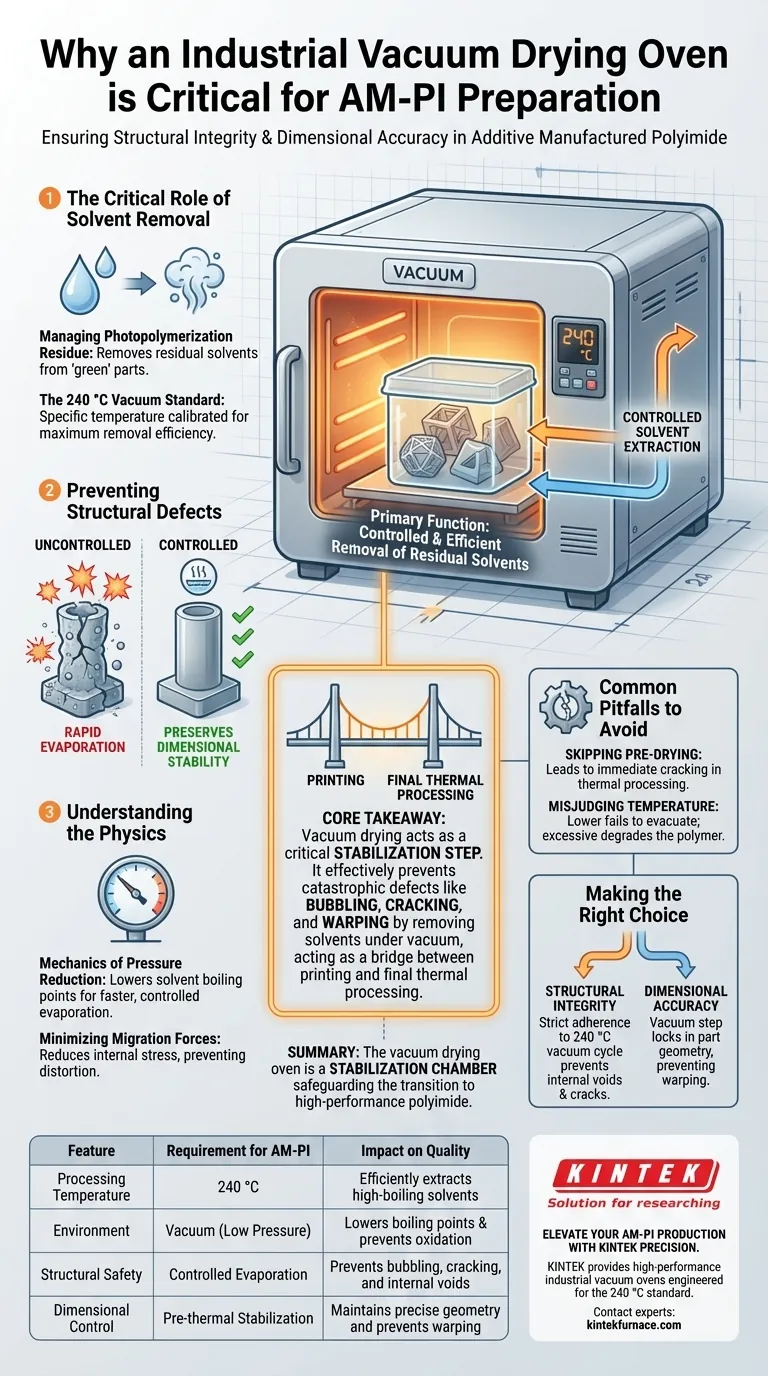

The primary function of an industrial vacuum drying oven in the preparation of Additive Manufactured Polyimide (AM-PI) is the controlled and efficient extraction of residual solvents. By subjecting photopolymerized parts to a vacuum environment at 240 °C, manufacturers ensure that volatile chemicals are removed without triggering destructive physical changes in the material.

Core Takeaway Vacuum drying acts as a critical stabilization step that effectively creates a bridge between printing and final thermal processing. By removing solvents under vacuum, you prevent the catastrophic defects—such as bubbling, cracking, and warping—that result from uncontrolled evaporation at high temperatures.

The Critical Role of Solvent Removal

Managing Photopolymerization Residue

Additive manufacturing of polyimide often relies on photopolymerization. This process inevitably leaves behind residual solvents within the formed part that must be fully evacuated before the material is considered finished.

The 240 °C Vacuum Standard

According to established protocols, these parts must be processed in a vacuum drying oven specifically at 240 °C. This temperature profile is calibrated to maximize solvent removal efficiency while the vacuum environment aids the process.

Preventing Structural Defects

Avoiding Rapid Evaporation

If residual solvents remain in the part during subsequent high-temperature thermal processing, they will evaporate instantaneously. This rapid gas expansion creates internal pressure that forces the material apart, resulting in bubbles and cracks.

Preserving Dimensional Stability

The vacuum drying step mitigates the risk of deformation. By removing solvents gradually and thoroughly, the oven ensures the component maintains the precise geometry and structural integrity intended by the design.

Understanding the Physics

The Mechanics of Pressure Reduction

While specific protocols for polyimide dictate high temperatures, the fundamental advantage of a vacuum oven is the reduction of environmental pressure. Lowering pressure lowers the boiling point of solvents, facilitating evaporation that is both faster and more controlled than atmospheric drying.

Minimizing Migration Forces

In general drying applications, vacuum environments reduce the internal forces generated during evaporation. While critical for complex chemistries like catalysts, for polyimide, this principle helps ensure the material matrix is not stressed or distorted as the solvent exits the structure.

Common Pitfalls to Avoid

The Danger of Skipping Pre-Drying

It is a common error to assume that final thermal processing will handle solvent removal. This is incorrect. Skipping the vacuum drying stage introduces solvents directly to extreme heat, leading to immediate structural failure (cracking) rather than controlled drying.

Misjudging Temperature Settings

Adhering to the specific 240 °C requirement is vital for AM-PI. Lower temperatures may fail to evacuate specific high-boiling solvents used in polyimide synthesis, while excessive temperatures without vacuum could degrade the polymer chains before the solvent is cleared.

Making the Right Choice for Your Goal

To ensure the success of your AM-PI production, consider the following:

- If your primary focus is Structural Integrity: strict adherence to the 240 °C vacuum drying cycle is mandatory to prevent internal void formation and surface cracking.

- If your primary focus is Dimensional Accuracy: Utilize the vacuum step to lock in part geometry, ensuring that solvent off-gassing does not warp the component during final sintering or curing.

In summary, the vacuum drying oven is not merely a drying tool; it is a stabilization chamber that safeguards the transition from a printed "green" part to a high-performance polyimide component.

Summary Table:

| Feature | Requirement for AM-PI | Impact on Quality |

|---|---|---|

| Processing Temperature | 240 °C | Efficiently extracts high-boiling solvents |

| Environment | Vacuum (Low Pressure) | Lowers boiling points & prevents oxidation |

| Structural Safety | Controlled Evaporation | Prevents bubbling, cracking, and internal voids |

| Dimensional Control | Pre-thermal Stabilization | Maintains precise geometry and prevents warping |

Elevate Your AM-PI Production with KINTEK Precision

Don't let residual solvents compromise your additive manufacturing success. KINTEK provides high-performance industrial vacuum ovens engineered to meet the rigorous 240 °C standard required for polyimide stabilization.

Backed by expert R&D and world-class manufacturing, we offer customizable Vacuum, Muffle, and Tube systems designed to eliminate structural defects and ensure superior dimensional accuracy for your lab or production line.

Ready to optimize your drying process? Contact our technical experts today to find the perfect solution for your unique high-temperature material needs.

Visual Guide

References

- Heather D. Wotton, Christopher B. Williams. Enabling Additively Manufactured Electronics Through Laser Induced Graphene and Copper Deposition on Fully‐Aromatic Polyimides. DOI: 10.1002/admt.202401801

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is Spark Plasma Sintering (SPS) optimal for Ti2AlN ceramics? Achieving 99.2% Purity and Maximum Density

- What is the function of a vacuum annealing furnace for Cu/CuFeO2/CZTS films? Enhancing Solar Cell Heterojunctions

- Why Use a Vacuum Drying Oven for Fire-Retardant Coatings? Ensure 100% Data Accuracy

- What is the purpose of using vacuum testing equipment? Achieve 100% Casting Quality via Density Index

- Can you braze in a vacuum? Achieve Unmatched Joint Cleanliness and Strength

- What are the key advantages of using a vacuum arc furnace? Achieve Unmatched Purity and Performance

- What role does a vacuum furnace play in the reduction of GO to rGO? Optimize Your High-Purity Graphene Composites

- Why is a two-step cooling system necessary for titanium hydrogenation? Protect Your Alloy’s Integrity