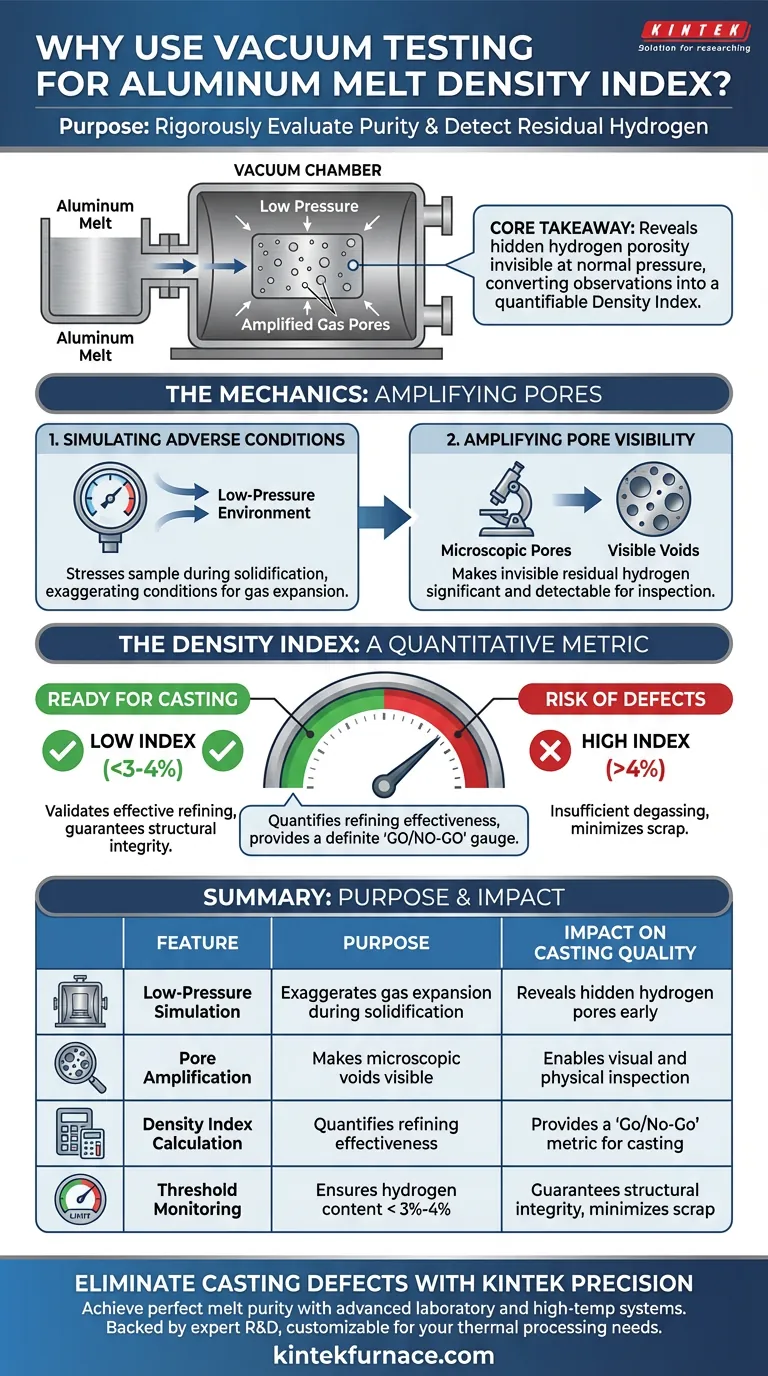

The primary purpose of using vacuum testing equipment is to rigorously evaluate the purity of aluminum melts by detecting the presence of residual hydrogen. By solidifying a sample under a simulated low-pressure environment, the equipment amplifies the formation of gas pores, allowing technicians to calculate a "density index" that quantitatively validates the effectiveness of the refining process.

Core Takeaway Vacuum testing acts as a critical quality control checkpoint, revealing hidden hydrogen porosity that might otherwise go undetected until casting is complete. It transforms subjective observations into a quantifiable density index, ensuring the melt meets specific purity thresholds—typically below 3% to 4%—to guarantee the structural integrity of the final component.

The Mechanics of Melt Evaluation

Simulating Adverse Conditions

Vacuum testing does not merely observe the melt; it actively stresses the sample. The equipment creates a low-pressure environment during the solidification phase of the aluminum sample.

This simulation is designed to exaggerate conditions that favor gas expansion. It forces dissolved gas to precipitate out of the solution earlier and more aggressively than it would under standard atmospheric pressure.

Amplifying Pore Visibility

The core function of this low-pressure simulation is to amplify the appearance of pores. Small amounts of residual hydrogen that might remain invisible or microscopic at normal pressure become significant, visible voids under vacuum.

This amplification makes it possible to visually and physically inspect the sample for internal defects. It converts a potential, invisible risk into an observable physical characteristic.

The Role of the Density Index

Quantifying Refining Effectiveness

The "density index" is the calculated metric derived from this test. It serves as a direct report card on the effectiveness of your refining process.

Rather than guessing if the melt is clean, the density index provides a hard number. If the index is high, the refining or degassing process was insufficient; if low, the melt is ready for casting.

Guarantees for Casting Quality

The ultimate goal of determining the density index is to guarantee casting quality. By establishing a quantitative baseline, you prevent defective metal from entering the mold.

This predictive step minimizes scrap rates and ensures the mechanical properties of the aluminum meet the required specifications.

Understanding the Limits

The Importance of Specific Thresholds

A common pitfall is treating the density index as an arbitrary number rather than a strict limit. The reference highlights that the hydrogen content must be below a specific limit, such as 3% to 4%.

Data without a threshold is useless. The test is only effective if the operator strictly adheres to these pre-defined pass/fail limits.

Simulation vs. Reality

It is important to remember that this test is a simulation of solidification. While it accurately predicts the potential for porosity, it assesses a sample, not the casting itself.

Therefore, the density index should be viewed as a gateway metric. It confirms the potential of the melt to produce a sound casting, provided the downstream casting process is also controlled.

Making the Right Choice for Your Goal

To utilize vacuum testing effectively, align the data with your specific production needs:

- If your primary focus is Process Validation: Use the density index to immediately verify if your degassing equipment is functioning correctly or if your refining time needs adjustment.

- If your primary focus is Product Certification: Enforce a strict cutoff (e.g., maximum 3% density index) to ensure every batch meets the mechanical safety standards required for the final application.

By using the density index as a definitive "go/no-go" gauge, you transform casting from a game of chance into a controlled engineering process.

Summary Table:

| Feature | Purpose | Impact on Casting Quality |

|---|---|---|

| Low-Pressure Simulation | Exaggerates gas expansion during solidification | Reveals hidden hydrogen pores early |

| Pore Amplification | Makes microscopic voids visible | Enables visual and physical inspection |

| Density Index calculation | Quantifies refining effectiveness | Provides a "Go/No-Go" metric for casting |

| Threshold Monitoring | Ensures hydrogen content < 3%-4% | Guarantees structural integrity and minimizes scrap |

Eliminate Casting Defects with KINTEK Precision

Don't leave your aluminum quality to chance. KINTEK’s advanced laboratory and high-temp systems empower you to achieve perfect melt purity through precise density index monitoring. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of your thermal processing.

Ready to optimize your refining process? Contact us today to discover how our specialized equipment can enhance your lab's efficiency and guarantee the integrity of every component you cast.

Visual Guide

References

- Ladislav Socha, Petr Nuska. Assessment of refining efficiency during the refining cycle in a foundry degassing unit in industrial conditions. DOI: 10.1038/s41598-024-51914-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What role does a vacuum annealing furnace play in evaluating Ag2S1-xTex phase stability? Map Material Limits Precisely

- What is the role of a vacuum oven or vacuum furnace in the preparation of ordered porous magnesium oxide via the nanocasting method? Ensure High-Fidelity Material Replication

- Why is a vacuum furnace beneficial for applications requiring high purity? Achieve Unmatched Material Purity and Performance

- How does a heat treatment furnace modify Fe-Cu composites? Enhancing Strength and Toughness via Precision Thermal Cycles

- What functions does a high-density graphite mold serve in the SPS process? Beyond Shaping Materials

- How is a vacuum sintering furnace used in the metal powder metallurgy industry? Achieve High-Density, Pure Metal Parts

- How are high-temperature vacuum furnaces utilized in scientific research? Unlock Pure, Controlled Material Synthesis

- How does a vacuum environment affect heat transfer? Optimize Lithium Battery Drying with Conduction Mastery