A vacuum furnace is ideal for high-purity applications because it removes the very medium that causes contamination: the atmosphere. By operating in a near-total vacuum, it eliminates reactive gases like oxygen and moisture before the high-temperature process even begins, preventing unwanted chemical reactions and ensuring the material's integrity remains pristine.

The critical advantage of a vacuum furnace isn't just creating a clean starting environment; it's the continuous removal of impurities and byproducts throughout the entire heating cycle, actively protecting the workpiece from contamination.

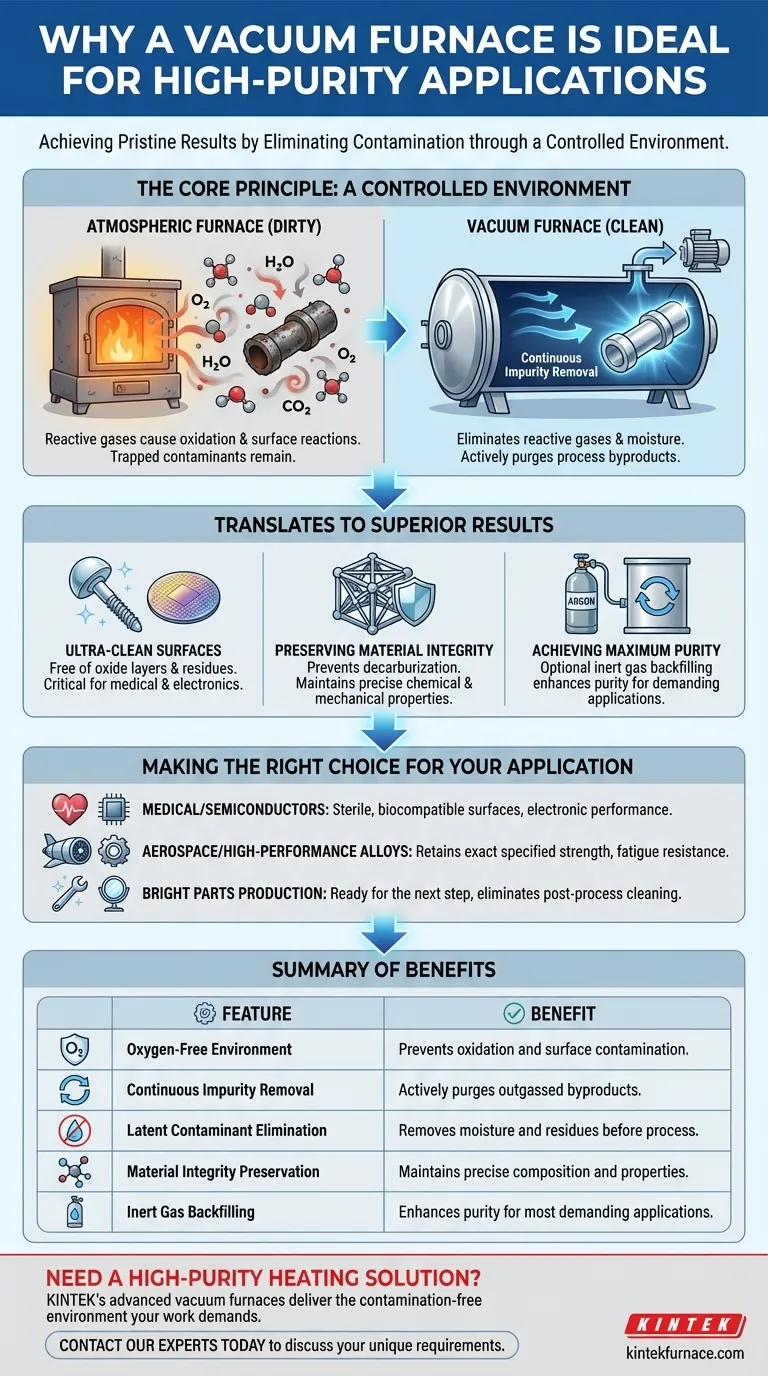

The Core Principle: A Controlled Environment

A standard atmospheric furnace heats materials in the presence of air, which is a mixture of nitrogen, oxygen, water vapor, and other trace gases. At high temperatures, these gases can aggressively react with the surface of a part. A vacuum furnace fundamentally changes this equation.

Eliminating Oxidation and Reaction

The most significant contaminant in many high-temperature processes is oxygen. When heated, metals readily react with oxygen, forming an oxide layer on their surface. This is undesirable in most precision applications.

A vacuum furnace removes virtually all the air from the heating chamber. Without oxygen present, oxidation cannot occur, leaving the part's surface bright, clean, and chemically unchanged.

Removing Latent Contaminants

Before a process starts, the chamber and the parts themselves may hold onto contaminants like moisture or residual cleaning agents. The initial pump-down phase of a vacuum furnace cycle turns these liquids into vapor, which is then pulled out by the vacuum system.

This ensures that the process begins in an exceptionally dry and clean environment, preventing reactions that could be caused by these hidden contaminants.

Actively Purging Process Byproducts

As materials are heated, they can release trapped gases or create volatile byproducts, a process known as outgassing. In an atmospheric furnace, these byproducts remain trapped, potentially re-contaminating the parts.

The vacuum system, however, is always running. It continuously captures and removes these outgassed impurities, actively purifying the environment throughout the cycle and protecting the workpiece from its own emissions.

How This Translates to Superior Results

The theoretical benefits of a controlled environment lead to tangible, critical outcomes for high-stakes industries like aerospace, medical, and semiconductor manufacturing.

Ultra-Clean Surfaces

For medical implants or semiconductor components, even microscopic surface contamination can lead to catastrophic failure. A vacuum furnace produces parts with exceptionally clean surfaces, free of the oxide layers and residues common with other heating methods.

Preserving Material Integrity

Certain processes, like the heat treatment of steel, are sensitive to carbon content. The presence of specific gases can cause decarburization, where carbon leaches from the steel's surface, weakening it.

By removing these reactive gases, a vacuum furnace ensures the material's precise chemical composition and intended mechanical properties are perfectly maintained.

Achieving Maximum Purity

For the most demanding applications, atmosphere purity can be further enhanced. A common technique involves pulling a deep vacuum and then backfilling the chamber with a high-purity inert gas, like Argon.

This cycle of pumping and refilling can be repeated several times to dilute any remaining trace contaminants, resulting in an almost perfectly pure environment for the process.

Making the Right Choice for Your Application

Choosing a vacuum furnace is a decision to prioritize control and material integrity over all else.

- If your primary focus is medical implants or semiconductors: A vacuum furnace is non-negotiable for achieving the sterile, contamination-free surfaces required for biocompatibility and electronic performance.

- If your primary focus is aerospace or high-performance alloys: A vacuum furnace is essential for preventing oxidation and decarburization, ensuring the material retains its exact specified strength and fatigue resistance.

- If your primary focus is producing bright, clean parts: A vacuum furnace eliminates the need for significant post-process cleaning, as parts emerge from the furnace ready for the next step.

Ultimately, using a vacuum furnace provides an unparalleled level of control over the processing environment, guaranteeing the highest possible purity and quality.

Summary Table:

| Feature | Benefit |

|---|---|

| Oxygen-Free Environment | Prevents oxidation and surface contamination |

| Continuous Impurity Removal | Actively purges outgassed byproducts during heating |

| Latent Contaminant Elimination | Removes moisture and residues before the process begins |

| Material Integrity Preservation | Maintains precise chemical composition and mechanical properties |

| Inert Gas Backfilling Capability | Enhances purity for the most demanding applications |

Need a high-purity heating solution for your critical applications? KINTEK's advanced vacuum furnaces are engineered to deliver the contamination-free environment your work demands. Leveraging our deep R&D and in-house manufacturing expertise, we provide custom solutions—including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems—tailored to your unique process requirements. Contact our experts today to discuss how we can help you achieve superior material integrity and flawless results.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy