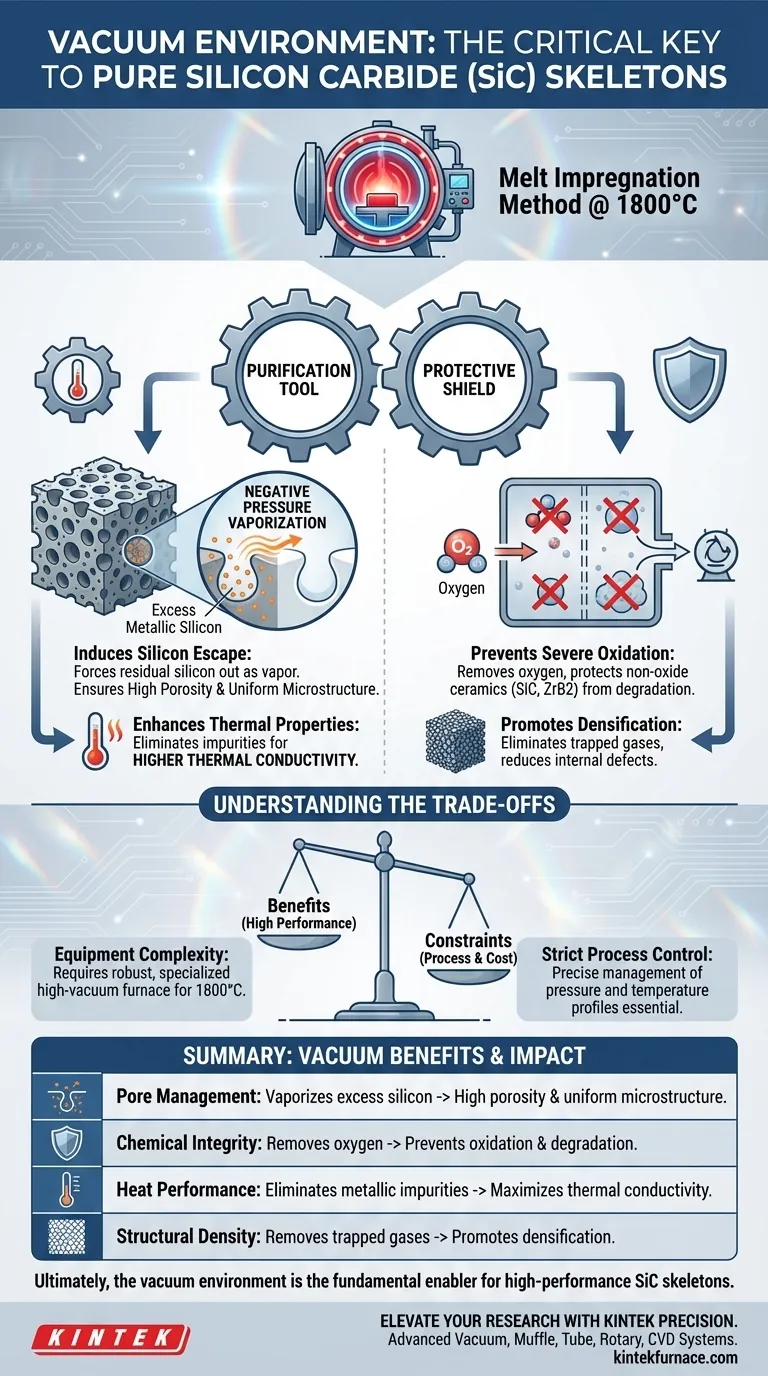

A vacuum environment is the critical operational requirement for achieving purity and structural integrity when preparing silicon carbide (SiC) skeletons via melt impregnation. Its primary function is to utilize negative pressure to vaporize and physically remove excess metallic silicon from the material's pores, ensuring the final product is a pure ceramic rather than a metal-ceramic composite.

The vacuum environment acts as both a purification tool and a protective shield. By leveraging negative pressure at 1800°C, it forces residual silicon out of the structure to ensure high porosity and thermal conductivity, while simultaneously eliminating oxygen to prevent the severe oxidation that degrades non-oxide ceramics at high temperatures.

The Mechanism of Purification

To create a high-quality biomimetic SiC skeleton, you must move beyond simple synthesis and focus on the refinement of the microstructure.

Inducing Silicon Escape

The primary reference highlights that raising the temperature to 1800°C within a vacuum furnace is essential for material refinement.

Under these specific conditions, the vacuum creates negative pressure.

This pressure differential induces excess metallic silicon to vaporize and escape from the skeletal pores.

Ensuring High Porosity

The removal of this residual silicon is what differentiates a dense composite from a porous skeleton.

By forcing the silicon out in vapor form, the process effectively "clears" the internal architecture.

This results in a biomimetic SiC ceramic template characterized by high porosity and a uniform microstructure.

Enhancing Thermal Properties

Purity directly influences performance.

By eliminating metallic impurities through vacuum extraction, the thermal impedance of the material is reduced.

This yields a final SiC skeleton with significantly higher thermal conductivity.

Preserving Chemical Integrity

While the primary reference focuses on physical purification, the vacuum plays an equally vital role in chemical preservation.

Preventing High-Temperature Oxidation

Non-oxide ceramics, such as SiC and ZrB2, are highly susceptible to degradation when exposed to oxygen at elevated temperatures.

The vacuum environment removes oxygen from the sintering atmosphere.

This prevents severe oxidation reactions that would otherwise compromise the mechanical properties of the ceramic.

Promoting Densification

Beyond oxidation, trapped gases can inhibit the structural integrity of the material.

The vacuum helps eliminate residual gases trapped inside the green body (the unfired ceramic).

Removing these gases reduces internal defects and further promotes the densification of the ceramic struts within the skeleton.

Understanding the Trade-offs

While a vacuum environment is necessary for high performance, it introduces specific processing constraints.

Equipment Complexity

Achieving a vacuum at 1800°C requires specialized, robust equipment capable of maintaining seal integrity under extreme thermal stress.

This significantly increases the capital intensity and complexity of the manufacturing process compared to atmospheric sintering.

Strict Process Control

The interplay between temperature and pressure must be precisely managed.

If the vacuum pressure is insufficient, residual silicon will remain, reducing porosity.

If the temperature profile is not maintained at the critical 1800°C threshold, the vaporization rate of the silicon may be too slow to be effective.

Making the Right Choice for Your Goal

The decision to utilize a high-vacuum, high-temperature furnace depends on the specific performance metrics required by your application.

- If your primary focus is High Purity and Porosity: You must use a vacuum to generate the negative pressure required to vaporize and extract excess metallic silicon from the pores.

- If your primary focus is Material Longevity: You must use a vacuum to remove oxygen and preventing the chemical degradation of the SiC structure during the high-temperature phase.

Ultimately, the vacuum environment is not just an optional feature; it is the fundamental enabler that transforms a raw ceramic precursor into a high-performance, biomimetic silicon carbide skeleton.

Summary Table:

| Feature | Vacuum Environment Benefit | Impact on SiC Skeleton |

|---|---|---|

| Pore Management | Vaporizes and extracts excess metallic silicon | Creates high porosity and uniform microstructure |

| Chemical Integrity | Removes oxygen from the sintering atmosphere | Prevents oxidation and degradation of non-oxide ceramics |

| Heat Performance | Eliminates metallic impurities | Maximizes thermal conductivity and reduces impedance |

| Structural Density | Removes trapped gases from the green body | Promotes densification and reduces internal defects |

Elevate Your Ceramic Research with KINTEK Precision

Unlock superior material performance with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems designed to meet the rigorous demands of your lab. Whether you are preparing biomimetic silicon carbide skeletons or specialized non-oxide ceramics, our systems are fully customizable to provide the precise negative pressure and 1800°C+ stability your process requires.

Ready to optimize your high-temperature synthesis?

Visual Guide

References

- Min Yu, Dou Zhang. Review of Bioinspired Composites for Thermal Energy Storage: Preparation, Microstructures and Properties. DOI: 10.3390/jcs9010041

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a vacuum drying oven ensure efficient encapsulation? Master Vacuum Impregnation for Phase Change Materials

- What are the advantages of using a vacuum drying oven for t-BTO nanoparticles? Preserve Critical Material Integrity

- How does an inert gas circulation system work in a vacuum furnace? Achieve Rapid, Controlled Cooling for Your Materials

- In which industries is vacuum brazing aluminum commonly applied? Essential for Aerospace, Automotive, Electronics, and Medical

- What is the significance of precise temperature control in a vacuum furnace? Ensure Quality, Consistency, and Reliability

- What are the key benefits of vacuum carburizing? Achieve Precision, Low Distortion, and Eco-Friendly Hardening

- Why is a high-temperature homogenization furnace treatment necessary for (CoCrNi)94Al3Ti3 alloys? Ensure Metal Purity

- What maintenance procedures are required for a vacuum heat treatment furnace? Ensure Peak Performance and Longevity