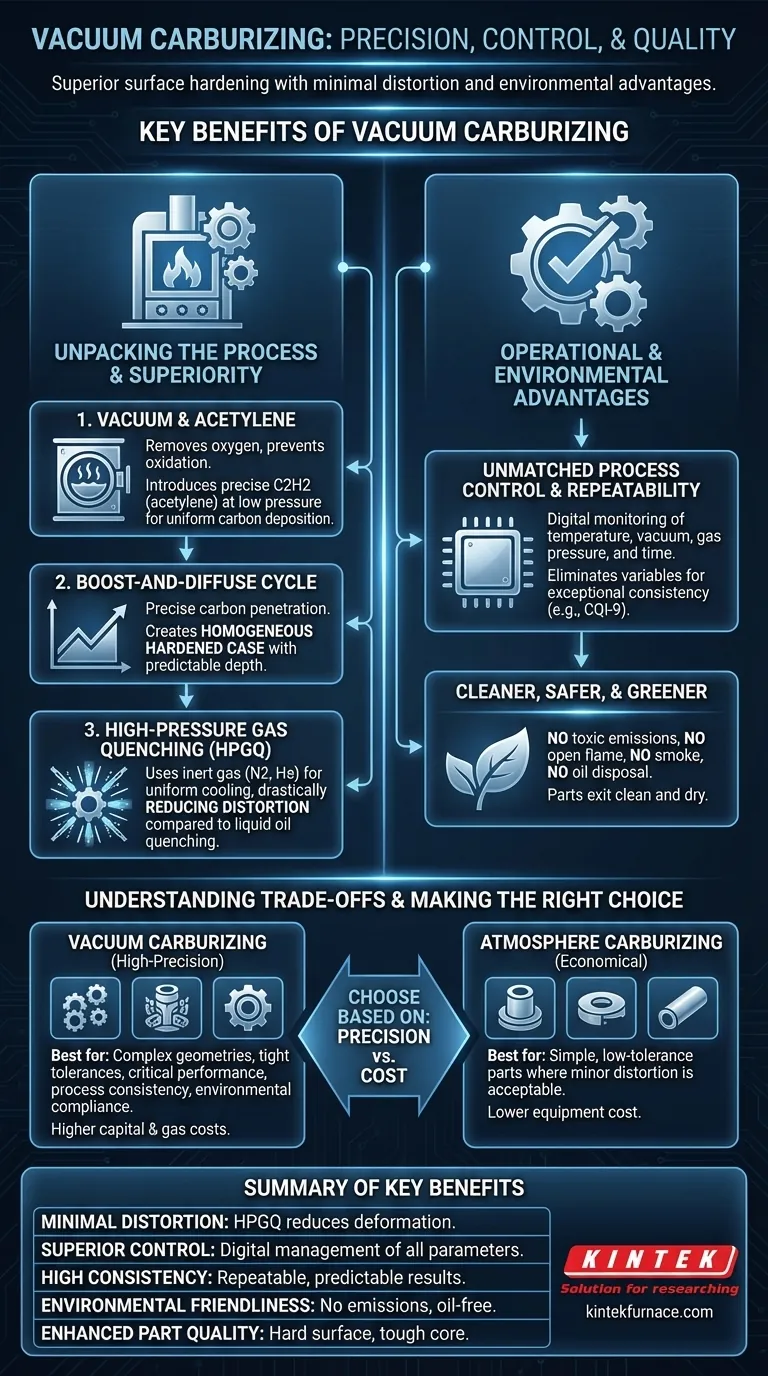

At its core, vacuum carburizing delivers superior results by replacing traditional processes with high-precision control. It is a case hardening technique that produces parts with a hard, wear-resistant surface and a tough, ductile core, but with significantly less distortion, higher consistency, and a cleaner environmental footprint compared to conventional atmosphere carburizing.

The fundamental advantage of vacuum carburizing is not just a better outcome, but a fundamentally more controllable and cleaner process. By removing atmospheric variables and using precise gas management, it transforms heat treatment from a bulk, variable process into a highly repeatable, digital-first manufacturing step.

Unpacking the Process: Why Vacuum Carburizing Excels

To understand the benefits, you must first understand the key differences in the process itself. Vacuum carburizing, also known as Low-Pressure Carburizing (LPC), operates on entirely different principles than its atmospheric counterpart.

The Role of Vacuum and Acetylene

The process begins by heating components in a furnace under a strong vacuum. This step is critical because it removes all oxygen and other atmospheric contaminants, preventing any surface oxidation from occurring.

Once at temperature, a precise amount of a hydrocarbon gas, typically acetylene (C2H2), is introduced at very low pressure. The high temperature causes this gas to break down, depositing a uniform layer of carbon atoms directly onto the steel's surface, which then diffuses inward.

Achieving Superior Metallurgical Quality

This controlled, "boost-and-diffuse" cycle allows for exceptionally fine-tuned carbon penetration. The result is a homogeneous hardened case with a highly predictable depth and carbon profile.

This hard case provides excellent wear resistance, while the component's core remains softer and more ductile. This combination creates a part that is highly resistant to surface wear while also being able to absorb shock and resist fracture.

Minimizing Distortion with Gas Quenching

Perhaps the most significant benefit is the drastic reduction in part distortion. After carburizing, conventional methods quench parts in a liquid oil bath, a thermally violent process that induces significant stress and geometric change.

Vacuum carburizing instead uses high-pressure gas quenching (HPGQ). An inert gas like nitrogen or helium is circulated at high velocity and pressure, cooling the part rapidly but uniformly. The flow, pressure, and velocity of this gas are precisely controlled, allowing the quenching intensity to be tailored to the part's specific geometry and material.

The Operational and Environmental Advantages

Beyond part quality, the process itself offers compelling benefits for modern manufacturing operations.

Unmatched Process Control and Repeatability

The entire vacuum carburizing cycle is managed by a microprocessor. Every critical parameter—temperature, vacuum level, gas pressure, and time—is digitally monitored and recorded.

This removes operator guesswork and environmental variables, ensuring that every batch is processed under the exact same conditions. The result is exceptional consistency and repeatability, which is vital for high-performance applications and for meeting stringent quality standards like CQI-9.

A Cleaner, Safer, and Greener Process

Vacuum carburizing is an inherently clean technology. There is no open flame, no smoke, and no sooty carbon byproduct that must be cleaned off parts.

It is an environmentally friendly process with no toxic emissions and no need to dispose of used quench oil. This creates a safer, cleaner working environment and eliminates the significant costs and liabilities associated with managing hazardous materials. Parts exit the furnace clean, dry, and ready for the next manufacturing step.

Understanding the Trade-offs

While powerful, vacuum carburizing is not a universal replacement for all heat treatment. Acknowledging its limitations is key to making an objective decision.

Equipment and Consumable Costs

Vacuum furnace technology represents a higher capital investment than traditional atmosphere furnace lines. The gases used, such as high-purity acetylene and nitrogen or helium for quenching, can also be more costly than the bulk gases and oils used in conventional methods.

Suitability for the Application

For simple, low-tolerance components where minor distortion is acceptable, the lower cost of traditional atmosphere carburizing may be a more economical choice. The precision of vacuum carburizing provides the most significant return on investment for parts with complex geometries, tight tolerances, or critical performance requirements.

Making the Right Choice for Your Components

Selecting the correct carburizing method requires aligning the process capabilities with your component's engineering and business goals.

- If your primary focus is high-precision parts or complex geometries: The minimal distortion from high-pressure gas quenching makes vacuum carburizing the superior choice.

- If your primary focus is absolute process consistency and traceability: The digital control and data logging of vacuum carburizing offers unparalleled repeatability and quality assurance.

- If your primary focus is environmental compliance and operational cleanliness: The emission-free, oil-free nature of the vacuum process provides a clear and immediate advantage.

- If your primary focus is minimizing cost on simple, non-critical parts: Traditional atmosphere carburizing may remain the more economical solution.

Ultimately, choosing vacuum carburizing is an investment in predictability, precision, and quality.

Summary Table:

| Key Benefit | Description |

|---|---|

| Minimal Distortion | Uses high-pressure gas quenching for uniform cooling, reducing part deformation. |

| Superior Process Control | Digital monitoring ensures precise temperature, pressure, and time management. |

| High Consistency | Repeatable results with predictable carbon penetration and case depth. |

| Environmental Friendliness | No toxic emissions, oil-free process, and cleaner operations. |

| Enhanced Part Quality | Hard, wear-resistant surface with a tough, ductile core for durability. |

Upgrade your heat treatment process with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering superior performance, reduced distortion, and eco-friendly operations. Contact us today to discuss how we can optimize your carburizing processes and boost your manufacturing efficiency!

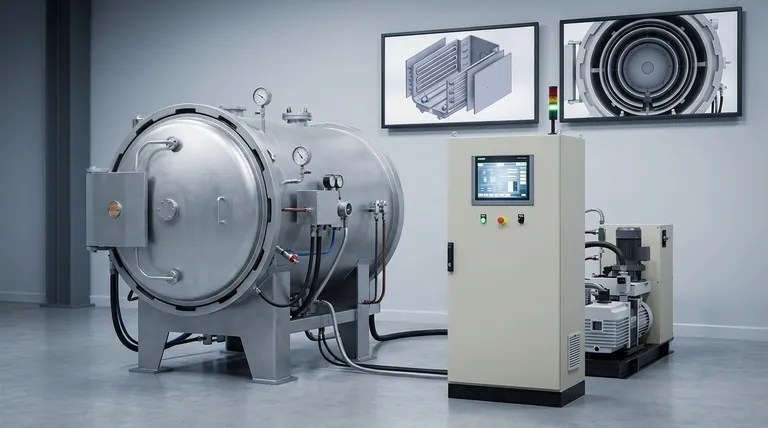

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures