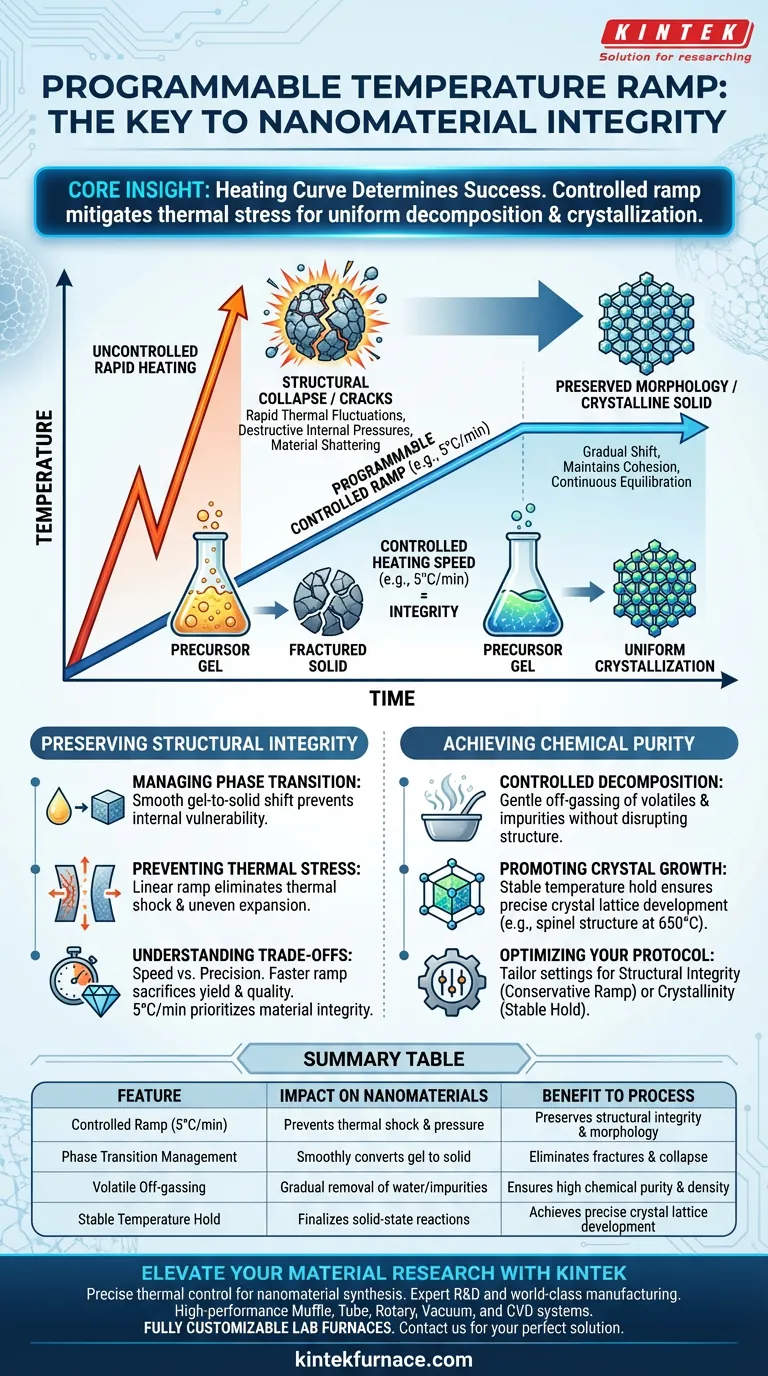

A programmable temperature ramp rate is critical for preserving the structural integrity of nanomaterial precursors during thermal processing. By enforcing a controlled heating speed, such as 5°C per minute, you prevent rapid thermal fluctuations that lead to destructive internal pressures. This control is the only way to successfully navigate the delicate transition from a precursor gel to a crystalline solid without causing the material to collapse.

Core Insight: The difference between a high-quality nanostructure and a failed batch often lies in the heating curve. A programmable ramp mitigates thermal stress, allowing the material to decompose and crystallize uniformly rather than shattering under the pressure of rapid temperature changes.

Preserving Structural Integrity

Managing the Phase Transition

Processing nanomaterials often involves converting a precursor gel into a solid. This is a significant physical transformation that creates vulnerability within the material.

If this transition happens too quickly, the material cannot adapt to its new state. A programmable ramp ensures this shift occurs gradually, maintaining the material's internal cohesion.

Preventing Thermal Stress

Rapid heating causes uneven expansion and internal pressures. When the temperature creates stress inside the material, the delicate nanostructure can fracture or collapse entirely.

By utilizing a steady ramp rate (e.g., 5°C/min), you eliminate the thermal shock that leads to these structural failures. This linear increase allows the material to equilibrate continuously as it heats.

Achieving Chemical Purity and Definition

Controlled Decomposition

Before the final crystal structure forms, the material must undergo thermal decomposition. This process removes residual water and volatile impurities trapped within the precursor.

If the furnace heats uncontrolled, these volatiles may expand violently on a microscopic level, destroying morphology. A controlled ramp allows these byproducts to off-gas gently without disrupting the solidifying structure.

Promoting Crystal Growth

The ultimate goal is to achieve a specific crystal arrangement, such as the standard cubic spinel structure found in high-quality NiFe2O4 nanoparticles.

Reaching a stable target temperature (e.g., 650°C) is necessary for the solid-state reaction that finalizes this structure. However, the path to that temperature determines whether those crystals form correctly or contain defects.

Understanding the Trade-offs

The Risk of Speed

The primary temptation in furnace operations is to increase the heating rate to reduce processing time.

However, saving time comes at the direct cost of yield and quality. Accelerating the ramp beyond the material's thermal tolerance almost guarantees structural collapse or incomplete phase formation.

The Cost of Precision

Conversely, a highly controlled, slow ramp rate extends the total processing time and increases energy consumption.

You must balance the need for structural perfection with operational efficiency. The rate of 5°C/min represents a proven baseline that prioritizes material integrity over speed.

Optimizing Your Thermal Protocol

To achieve the best results with nanomaterial precursors, tailor your furnace settings to your specific quality requirements.

- If your primary focus is Structural Integrity: Prioritize a conservative ramp rate (around 5°C/min) to minimize internal pressure during the gel-to-solid transition.

- If your primary focus is Crystallinity: Ensure your protocol includes a stable hold at the requisite annealing temperature (e.g., 650°C) to allow for full crystal lattice development.

Consistency in your heating profile is the single most important factor in reproducing high-quality nanoparticle morphology.

Summary Table:

| Feature | Impact on Nanomaterials | Benefit to Process |

|---|---|---|

| Controlled Ramp (e.g., 5°C/min) | Prevents thermal shock and internal pressure. | Preserves structural integrity and morphology. |

| Phase Transition Management | Smoothly converts precursor gel to crystalline solid. | Eliminates fractures and material collapse. |

| Volatile Off-gassing | Gradual removal of water and impurities. | Ensures high chemical purity and density. |

| Stable Temperature Hold | Finalizes solid-state reactions (e.g., spinel structures). | Achieves precise crystal lattice development. |

Elevate Your Material Research with KINTEK

Precise thermal control is the difference between a breakthrough and a failed batch. At KINTEK, we understand the delicate science of nanomaterial synthesis. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the most rigorous heating profiles.

Whether you need custom ramp programming or specialized atmosphere control, our lab high-temp furnaces are fully customizable to your unique research needs. Ensure the integrity of your next discovery—contact our technical specialists today to find the perfect furnace solution.

Visual Guide

References

- Changwei Shan, Liwei Mi. Co<sub>1−<i>x</i></sub>S@CNT composite with a three-dimensional skeleton for high-performance magnesium–lithium hybrid batteries. DOI: 10.1039/d3ma01089a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a muffle furnace operate? Uncover Its Efficient, Contamination-Free Heating Process

- What is a hydrogen muffle furnace and how does it work? Precision Heating with Hydrogen for Oxide-Free Results

- What role does a muffle furnace play in the curing process of GaN and TiO2? Optimize Your Photoanode Sintering

- Why is the type of controller important in a muffle furnace? Unlock Precision and Repeatability for Your Lab

- What type of temperature control does the basic muffle furnace have? Discover Simple, Accurate Heating Solutions

- What role does an industrial-grade high-temperature muffle furnace play in the calcination of Barium Titanate powders?

- What is the function of a high-temperature lift furnace in the sintering process of SSZ electrolyte pellets?

- How does the atmosphere control differ between muffle furnaces and drying ovens? Key Insights for Lab Efficiency